Today at Formnext in Frankfurt, Ultimaker unveiled new software updates and printing profiles developed in collaboration with leading materials companies. This complete solution offers customers an even greater range of materials for applications from prototyping to production, with a simpler 3D printing workflow.

Here’s a quick summary of the releases and updates, which we’re excited to be making available today:

Preconfigured profiles in Ultimaker Cura for Owens Corning, DSM, BASF, Clariant, and DuPont materials

Our new abrasion-resistant print core is available to order

Ultimaker Cura 3.6 delivers slicing and UX enhancements

Advanced materials from world-leaders

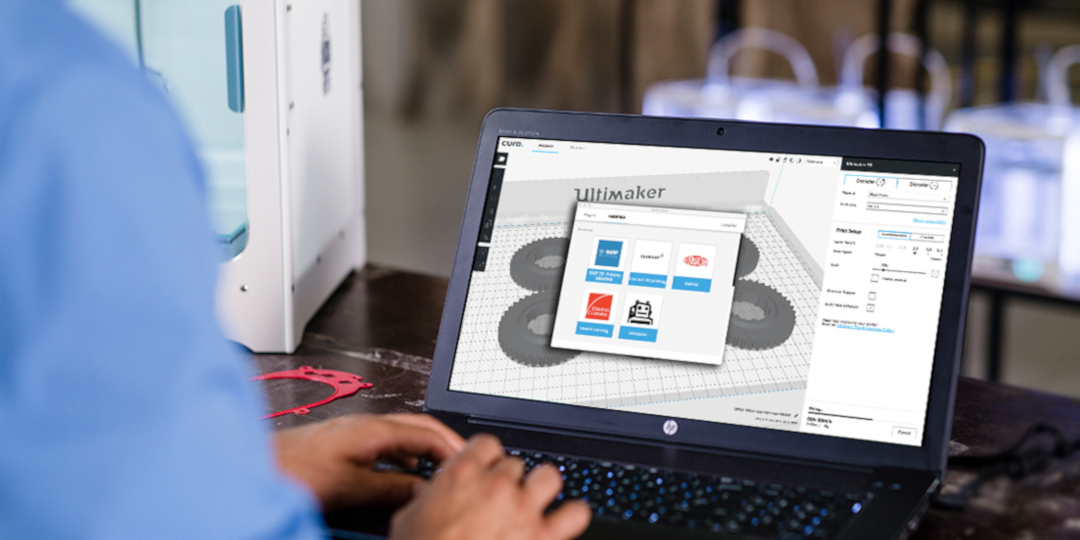

In the latest version of Ultimaker Cura (more on that below), you can now download preconfigured printing profiles for filaments from some of the world’s best-known materials companies.

Printing profiles optimized for world-leading materials can be downloaded in Ultimaker Cura

In addition to the Owens Corning and DSM materials announced earlier, we are delighted to offer BASF, Clariant, and DuPont printing profiles in Ultimaker Cura. The new profiles are:

BASF: PP GF30 is ideal for parts used in environments that require chemical resistance, such as piping or automotive applications under the hood. PET CF is an easy-to-process carbon fiber reinforced material, suitable for lightweight, strong, and stiff parts that require an impact resistance, for example drones

Clariant: Flame retardant PA6/66 using Exolit® and Flame retardant PA6/66 with 20% glass fibers using Exolit® can be used to produce parts such as switchgears, electrical enclosures, electronics, and automotive components that require flame retardancy and good mechanical properties. PET-G is a tough, chemical-resistant polyester with improved heat resistance

DSM: Novamid® ID1030 CF10, PA6/66 reinforced with carbon fibers, creates stronger, tougher and stiffer printed parts, matching the easy and fast printing of unreinforced plastics. Arnitel® ID2060 HT, a high performance TPC, combines sustained high temperature use with chemical resistance. Arnitel® ID2045, a very flexible TPC, is suitable for many applications, from footwear mid-soles to electronics. Novamid® ID1030 is a PA6/66 material for durable applications requiring good mechanical properties

DuPont: Zytel® 3D1000FL, an unreinforced polyamide with ultra-low shrinkage, and Hytrel® 3D41000FL, a polyester elastomer with shore D60 hardness showing similar properties in X, Y and Z direction, are both suitable for industrial, automotive and consumer product applications

Owens Corning: Glass-fiber reinforced Polypropylene (XSTRAND™ GF-30 PP) and Polyamide 6 (XSTRAND™ GF-30 PA6) unlock any application that require high-strength and durable parts that need to operate in a tough, extreme temperature environment, either outdoor or indoor.

You can download optimized material profiles for all these filaments from the Marketplace in Ultimaker Cura 3.6.

Material profiles from other leading companies such as Arkema, colorFabb, ElogioAM, Eastman, Henkel, igus, Matterhackers, Polymaker, and more will be added to the Marketplace soon.

A world-first in the 3D printing industry, these collaborations bring Ultimaker customers an even greater choice of materials with a variety of mechanical properties. Profiles in Ultimaker Cura created by the experts at these companies ensure you get high-quality and repeatable results every time – with no need to manually input parameters before printing.

Download the latest version of Ultimaker Cura to get started using optimized printing profiles for these materials.

Order the Ultimaker print core CC Red

Announced in September, our composites-ready print core is now available to order through our network of resellers.

The print core CC Red 0.6 has a wear-resistant ruby cone at its tip

The print core 0.6 CC Red is designed to withstand abrasive 3D printing, with a precision-machined 0.6 mm diameter nozzle and tough ruby tip. Its quick-swap design maximizes uptime with no tooling or manual calibration needed. And there’s no need to worry whether your nozzle can deal with the abrasion.

Developed in collaboration with engineer Anders Olsson, the print core is tested to print 10 kg of carbon fiber filament with no loss of quality, and 1,000 plus hours of extrusion.

Simply combine with a composite material of your choice for extremely durable end-use parts, or beautiful aesthetics on your prints.

Our print core 0.6 CC Red is compatible with the Ultimaker S5, comes with four spare Ultimaker S5 nozzle covers, available for €295 ($295). Order the print core 0.6 CC Red from your local reseller.

Ultimaker Cura 3.6

The world’s most-used 3D printing software gets a suite of slicing enhancements and improvements to the user experience. That’s not to mention the exclusive printing profiles from Owens Corning, DSM, BASF, Clariant, and DuPont available via the Marketplace.

Read our latest Ultimaker Cura blog to see full details of the release.

Complete production solution

These releases extend the power of our open and integrated ecosystem, so you can do more with Ultimaker hardware and software. See what Ultimaker technology can do for your business.