What’s it like to be a student administrator for a 3D printing lab space? What kind of experiences could you offer to a student at your own school by hiring them for such position? Find out in this special guest post from student Sabastian Moncayo!

I have been involved in additive manufacturing since August of 2015 when I began to attend the University of Texas at El Paso (UTEP). I am pursuing my degree in Metallurgical and Materials Engineering; I have an interest in the way materials respond to different conditions and how it is that you can harvest those unique characteristics. Currently, I work in the Learning Environments as part of the all-student staff that administers the four 3D printers used in their 3D pilot program. This dedicated group of student staff offers technical training and support, helps administer the lab and printing processes, and keeps the 3D printers in working condition.

Joining the Learning Environments 3D Printing Lab

I remember the first time I saw a working 3D printer. I was amazed by the way it goes from a computer design to palpable model. I printed several models that until this day, I still cherish. I was fortunate to be able to join the staff of the Learning Environments in late November of 2015, who were starting a 3D printing pilot program. I was lightly involved on the 3D printers for the first month or so, then started taking action and participating in the pilot program. I was astonished by the amount of attention that the program received from the students. An open 3D printing lab available for all students was something unheard of, at least here in our community. Most of the 3D printing labs that are here at the University of Texas at El Paso are reserved for specific majors such engineering or science, but not this one; here, everybody is welcomed.

As part of the pilot program, I started to learn how to keep the 3D printers working in good condition and about the basics of troubleshooting for the common problems that printers have. I also started to familiarize myself with 3DPrinterOS, which we use in our lab to be the medium between the students and the staff. Through this website, students are able to send the files that they wish to print. Then we carefully inspect the print models until we are able to print them.

The picture above shows me sitting at the 3D printing support desk, where students come for help or to pick up their finished prints. Some of the models on the shelves are ready for students to pick up, and some are decorative models that we printed for testing. Every day I start my day by looking at the files that were submitted for printing and making sure that they are ready to print. If a file has problems then I send an email to the submitter describing the problem (support material, orientation, scale down or up, etc). Most students email me back with additional questions or resend the file with no more problems, ready to print.

Helping students design and print at the lab

After a month, we began to give workshops on 3DPrinterOS and Tinkercad, which is a very user-friendly program to design 3D models. This pilot program captured the attention of many because it not only provided the service of printing 3D models but it also provided the necessary help for people that were new to the 3D printing “phenomenon.” The students that began to print ranged from engineering majors all the way to writing and liberal arts majors. The fact that so many people were so interested pushed me to inform myself as much as possible. I was determined to provide good service to everybody that wanted to transfer an idea to a three-dimensional model. We also had several engineering classes that participated by designing and printing small bridges. There was also an art class that utilized the printers to print art projects for the class, that consisted of printing geometric figures such as triangles and rectangles in order to put them together into abstract pieces of art.

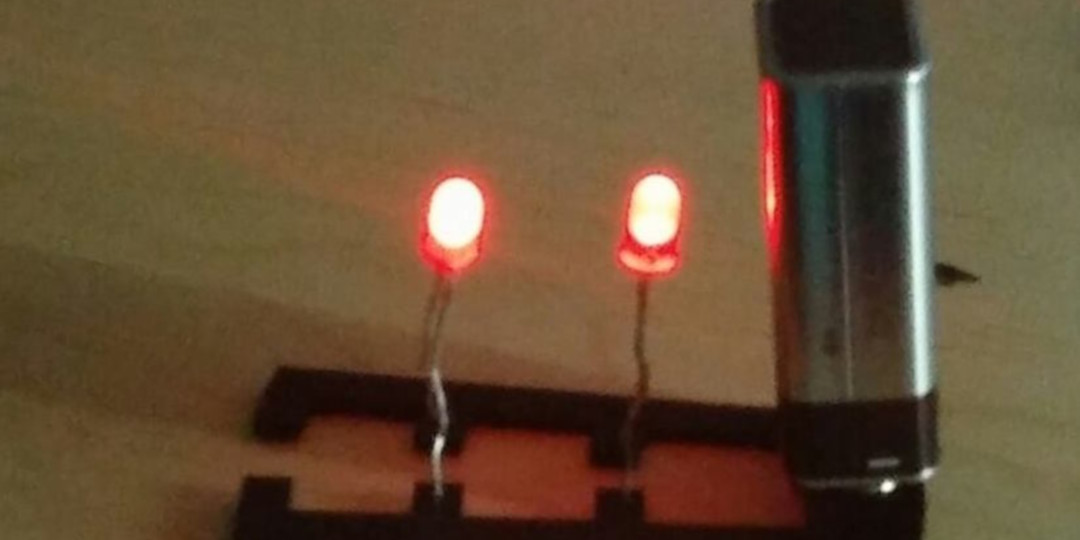

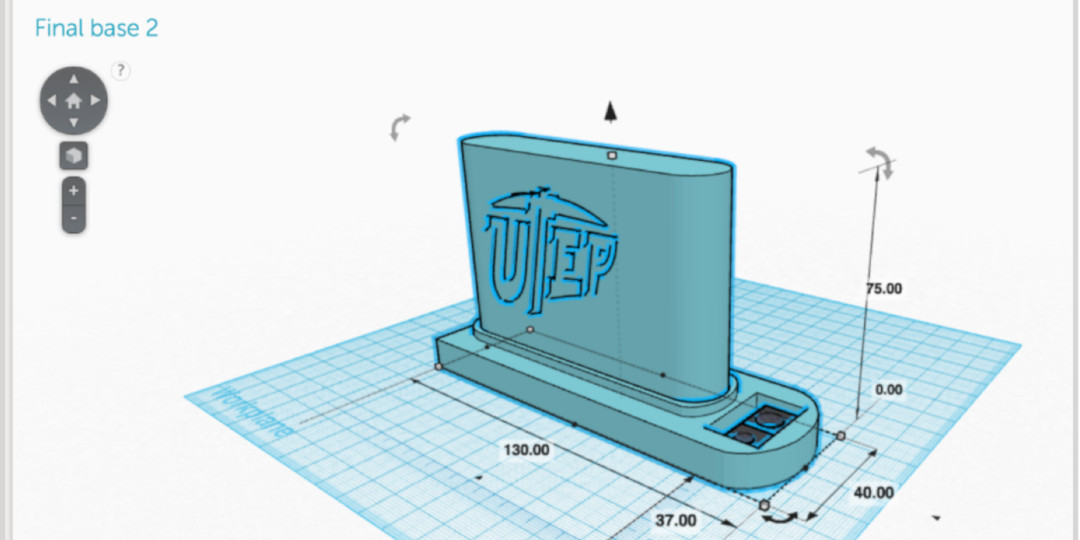

As the program continued, each and every day my team and I familiarized ourselves more and more with the printers. I began to work closely with Hector Lugo Nevarez one of the main persons in charge of developing and expanding the pilot program. I also began to design models for different purposes, such as souvenirs for a recent summer camp and special requests for replicating manufactured parts. I also worked with Hector Lugo Nevarez to test a new conductive filament that we had just acquired. Along with co-worker Erik Lopez, we were able to design a 3D-printed lamp whose circuit was also completely 3D printed out of the conductive material. The pictures below show the lamp circuit completely 3D printed with the conductive material and the design for 3D printing the housing of the bottom of the lamp.

The student staff also maintains the 3D printers. This is Karla Ayala, one of the students on the staff of the 3D pilot program, replacing the nozzle of one of our printers. It is incredible the amount of dedication my coworkers have for this program. It is also amusing just how much attention this pilot program has received. Since the enrollment during the summer was small we stopped printing and focused that time to maintain the 3D printers making sure everything was ready for the Fall semester. A week ago, we resumed 3D printing again for the new academic year, and the response was astonishing. Within a day, people were coming into the lab to ask for help or to pick up their new prints. Many people came by just to ask “Is it true you guys are starting to print again?” The response of the UTEP community was amazing. What is even more incredible is that the Fall semester has not even started yet. I am sure that even more students will begin to come to claim their models or simply to explore the lab once school starts again.

Into the future

In my opinion, we still have a long way to go. I believe, and I am sure that many of my coworkers would agree, that we should have at least one more printer available in order to deliver better results to the students. Some students get frustrated during our busy times when their designs can take over a week to print. We have only four printers, but more than 430 students are interested in printing. That means a ratio of over 100 people per printer -- and that’s only if one of the printers does not have a malfunction. A new school year is about to begin and I am sure that many incoming freshmen will be excited about the idea of 3D printing, and that means that our program will only continue to grow.

This high demand is also a problem for materials. Since the 3D printing lab is free, the PLA runs out fast. If we could set up a system in which students don’t pay for the service but rather just for the PLA, then we wouldn’t have to slow down our printing rate due to the fear that we might run out of PLA. This would also help the student develop awareness of how 3D printing works and pay attention to what they are doing in order to save money. They would learn about layer height, bottom/top thickness, shell thickness, print speed, and infill since all of these things are factors that determine the weight and outcomes of their 3D printed models.

I am sure that the future of the Learning Environments 3D printing pilot program has even greater things in its future. I strongly believe in this pilot program because I see the determination on both sides: the students that are eager to come and print, and the staff that is enthusiastic to help those students that come in. With the help of my co-workers, I will continue to gain more knowledge and experience in order to provide outstanding service to the students who use our 3D printers.