Under a high-arched roof and 40-ton gantry cranes, New Lab holds echoes of the former factory that built battleships before it built businesses. Every day its members are changing the way companies think about the prototyping and manufacturing process. Robotics, IoT, Machine Learning, Additive Tech, Blockchain, Urban Tech, and Life Sciences, are among the disciplines filling the offices, lofts, and designated work lounges at New Lab, with dedicated member-access fabrication shops that enable around the clock prototyping, testing, and design iteration.

New Lab innovators print their way to faster iterations and design freedom

In an era when startup incubators and co-working spaces spin up as a matter of course in densely populated urban centers, New Lab offers a fresh take on what it means to bring people and companies together to work under one large roof. Extending over 84,000 square feet in the historic Brooklyn Navy Yard, New Lab is home to over 100 member companies, including more than 500 designers, engineers, entrepreneurs, executives, and product realization specialists.

3D printing technologies play a unique role for New Lab member hardware companies, as flexible, general-purpose fabrication solutions that can cross the digital divide from design files to tangible models of physical products. As a result, 3D printers are often central to the design iteration process for New Lab companies, promoting communication, field-testing, and creativity at each step of the prototyping phase.

A 3D printing solution

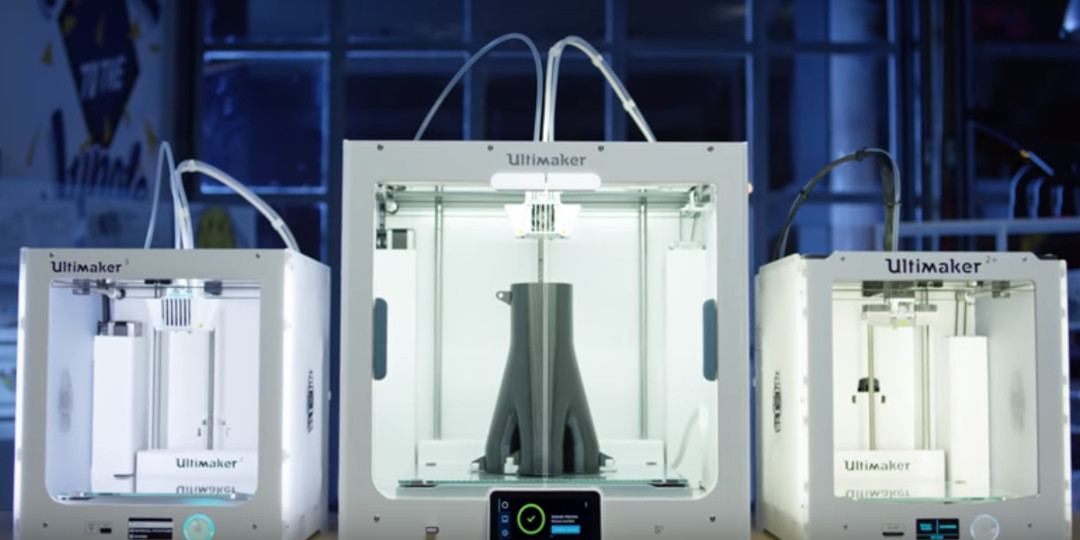

“When Ultimaker joined New Lab as a member company, we brought with us a fleet of our latest-model professional desktop 3D printers and hundreds of spools of free filament that we made available for members to use with full 24-hour access at no charge for the first year and a half,” says Matt Griffin, Ultimaker’s Director of Community for North America. The experiment was aimed to establish a high-velocity, real-world laboratory for addressing immediate requests from New Lab members at work on their projects in progress.

With a boost to their overall fabrication capacity and capability, New Lab was able to eliminate a few high-cost, high-maintenance industrial FFF options, to completely replace them with these units that were made available to members with greater access and lower cost per use. “For the members who might be interested in 3D printing, and in integrating 3D printing into their workflow, the largest barrier was that they either assumed that 3D printing could do anything, or that it couldn’t do the thing they needed it to,” says Alexander Susse, New Lab’s Director of Additive Manufacturing.

The way to get people to truly understand the usefulness of 3D printing is to just give them the tools and let them start trying to print things. You can’t really do that with some of the more industrial options.

Today, New Lab's 3D Printing Lab features twelve Ultimaker 3D printers for community use, fully-integrated into the member services available throughout the building. With these printers readily available to reserve day or night, the possibility for innovation doesn’t punch out.

From industrial to desktop

Replacing industrial 3D printers with a desktop option reflects an emerging industry trend where manufacturers, design firms, engineering firms, and educators substitute a high-capital investment machine with racks of desktop machines for the same initial investment. As 10xBETA CEO Marcel Botha points out, industrial additive manufacturing companies might have missed the mark on providing critical prototyping conditions.

“With our Ultimakers,” Marcel says, “we can finally use 3D printers for experimentation on the fly. The original aim of iterating and rapid prototyping is, at the end of the day, to prototype – not to produce costly artifacts at each stage. When I print using SLS or high-end FFF solutions, I feel the parts that cost so much to produce are precious – but the only requirement for the printed parts is that they are something my team and I can look at for five minutes and then throw away. We’d rather buy three more Ultimakers than one $9k entry-level industrial-grade machine.” Marcel believes that professional desktop 3D printers match and address his team’s actual prototyping needs.

Once he eased into the habit of 3D printing, Tony Kauffmann, Product Development Engineer at Voltaic Systems, says it was simple for him to transform Ultimaker into a powerful tool in his production arsenal. “It definitely speeds things up,” Tony says. It allowed Voltaic to remove several of the middle steps that would’ve hindered their factories. “Timelines overall have shrunk, but I’d say the real advantage for us is that it allows us to improve the quality of our products.”

New Lab Resident Eric Forman of Eric Forman Studio says that 3D printing has changed the way he thinks about what he can produce as a designer, as he considers all of the roles that 3D printers like Ultimaker might offer for improving the practicality and functionality of his other tools.

“I would say three-quarters of what I print is probably to assist with another tool,” Eric says. As he combines interactive and responsive technology with natural materials like wood, it’s important that everything he produces works in harmony and serves a purpose. 3D printing works to bridge and cohere the disparate materials.

Eric considers, “Is there a way to do this with 3D printing that’s gonna be better?” These days he tends to think about 3D printing much earlier in the construction process. “And now that I’ve expanded to using the actual 3D-printed parts in the final piece as the material itself, and not just as a helper,” he says, ”it’s a whole different ball of wax.”

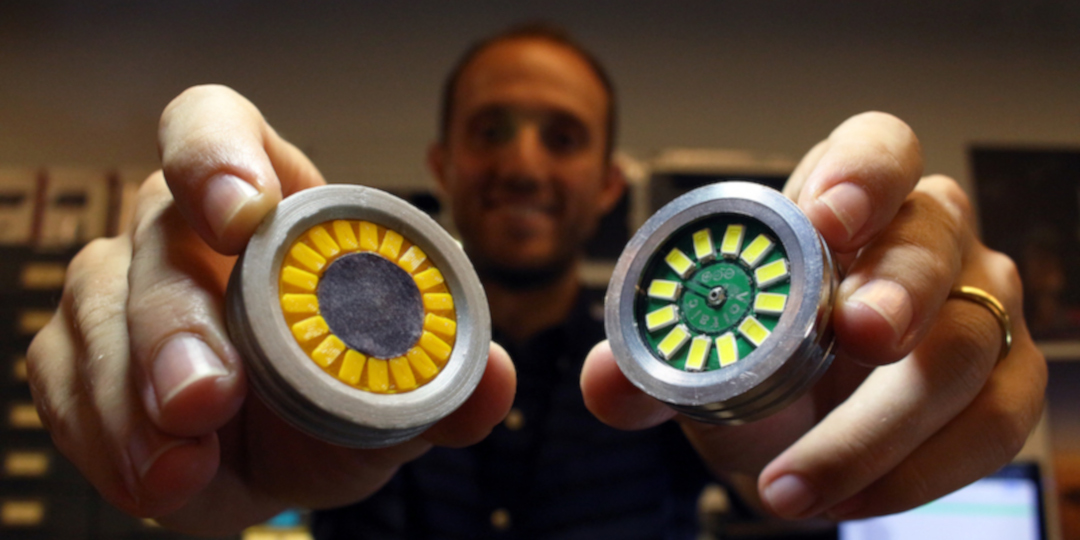

Like Eric, Arya Tabatabai’s idea of 3D printing’s place in the manufacturing process evolved after joining New Lab. A Mechanical Engineer who works as a free agent for companies like SILO, Arya says that he’s gained competency from using the tools New Lab has made available. He’s discovered how useful it is to create “looks-like” models of 3D printed parts by sanding and finishing the prints, which he can hand off to an Industrial Designer for immediate feedback.

Expediting the prototyping process

Of the tools available at New Lab, Arya finds desktop 3D printers to be the most valuable and user-friendly. “The Ultimakers are great tools for prototyping in general,” he explains. “I've done a lot of research on desktop 3D printers, and from what I can see the Ultimakers are one of the best, if not the best in terms of the FFF category. It's a strength to my work just using them, being able to think up something, CAD something up, and get it in front of you. Whether it's in an hour or a day, that speaks for itself as to how beneficial it is.”

Looking ahead, the prototyping process has pushed New Lab members to consider the future implications of these versatile technologies – whether through investing in their own equipment or expanding their horizons with tools they had not previously considered. With the cost barrier of more expensive machines, they’re content to use the fully capable tools already available to them.

By eliminating the time consuming and costly steps between ideation and manufacturing, these innovators have all found the Ultimaker delivers more freedom to improve their products. Their creative solutions and cross-company collaborations are a testament to just how successfully New Lab has transformed their working environments. Spaces like New Lab are opening doors to greater networking opportunities and speedier production processes, giving capable fast-moving hardware companies a chance at success.