Faster in-house iteration with desktop 3D printing

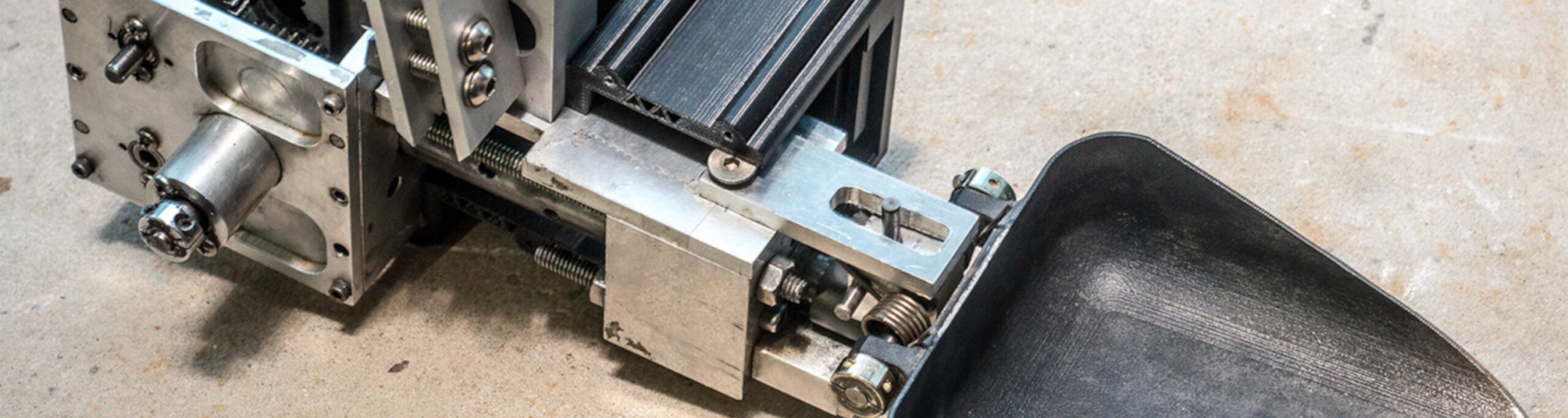

When we are building a new type of robot, there’s no point in getting metal parts when coming up with a new design because it is too expensive and takes too long. We’ll print something that same day, put bearings, bushings, and other components into it, and integrate a motor into it. This allows us to explore different parts of a robot that might be needed and modify any design that does not work.

- Yoni Saltzman, Project Engineer, Honeybee Robotics

Challenge and solution

Challenge

Engineers and staff at Honeybee Robotics are looking for quick, low-cost fabrication solutions in their office to support the multiple rounds of iteration for the early stages of their designs -- while they are still validating concepts and establishing project parameters.

Solution

Ready access to Ultimaker professional desktop 3D printers onsite boosts productivity for new mechanical design projects. Engineers and designers are able to quickly and inexpensively produce functioning mechanical studies from the earliest stages of a project’s development.

Results

New mechanisms explored: Test robotic systems ideas before the project constraints are fully known — this helps engineers and designers to learn quickly what does and doesn’t work. With this process in place, teams can iterate freely without straining the budget.

Design improvements shared: Not every client and project stakeholder question can be satisfied by a technical drawing and an updated project brief—giving your collaborators a physical mockup to hold, interact with, and inspect offers a far richer and deeper understanding of a subject.

Concept models fabricated: Unlike traditional model building, desktop 3D printing allows engineers to tweak scale at the point of fabrication: miniaturizing large assemblies to present an overall target, or enlarging a single critical feature for the purpose of discussion and investigation.

Product planning simplified: When designing equipment that is destined to travel hundreds of thousands of miles to perform to operations on the surface of another planet, it is worth exploring every possible scenario and iteration for your design here on Earth first.