Our vast community of 3D printing experts not only have in-depth knowledge of Ultimaker products, they’re also happy to share their expertise with everyone who asks. Helping users to achieve more with their 3D printer. Today, the focus is on one of our most prolific contributors, Anders Olsson, and how his work led to the development of a new wear-resistant print core.

About Anders

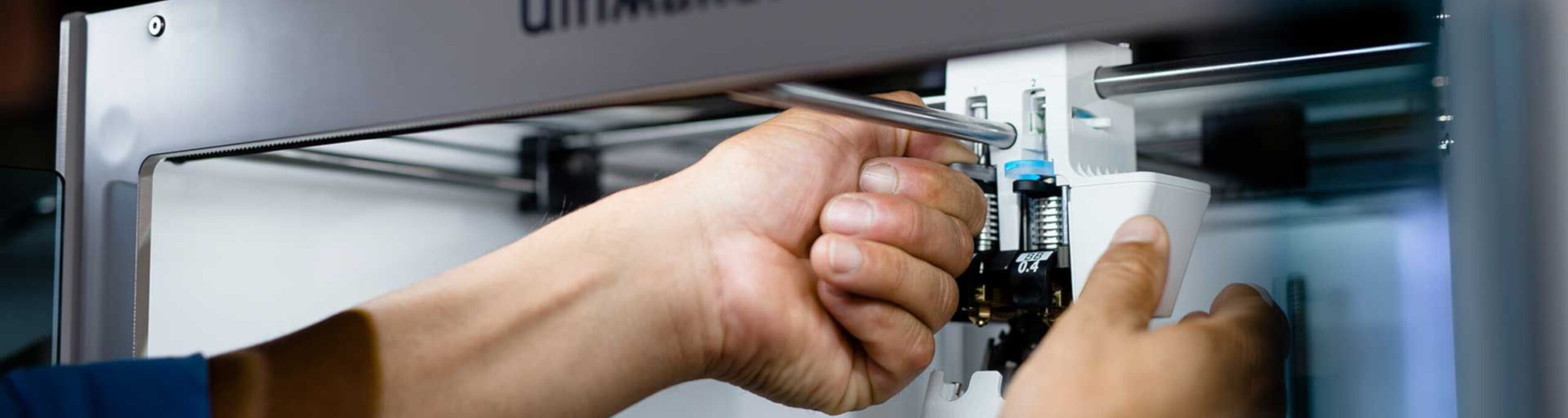

Anders is the mind behind the Olsson Block, a development of the Ultimaker 2+ nozzle he created in order to 3D print with boron carbide. Now, Anders is keen to elaborate more on another project he’s involved with. Our print core CC Red 0.6 – a wear-resistant ruby nozzle for the Ultimaker S5, with the same quick-swap design as our other print cores.

Anders is a research engineer at Uppsala University in Sweden. He’s well-known in his industry for 3D printing boron carbide composites for nuclear shielding (boron carbide is one of the world’s hardest known materials).

Developing a wear-resistant nozzle

To print with this highly abrasive material, Anders needed a longer lasting nozzle than the standard brass option. Printing with boron carbide, it would be destroyed during the first print and contaminate the printed part with its residue. Besides affecting the nozzle diameter through wear, abrasive materials also erode the ‘shoulder’ on the tip of a nozzle. Both types of wear cause print quality issues.

Anders’ interest in an abrasion-resistant print core came from printing with enriched boron carbide, which has much better performance than natural boron carbide, but is considerably more expensive. Dual extrusion with the Ultimaker 3 and Ultimaker S5 made it possible to combine natural and enriched boron carbide in the same print, using the more expensive material only in spots where it is really needed. Anders liked the reliability of the print cores, but needed more wear resistance, which is what inspired him to modify a print core with a ruby nozzle tip.

Why ruby?

Anders selected ruby because it is incredibly hard, chemically stable, non-toxic and not dangerous when worn down (unlike, for example, tungsten carbide, where the cobalt binder would cause problems in a neutron environment).

The ruby offers a consistent performance for general printing with any abrasive materials too.

Besides abrasive materials, Anders also used the ruby-tipped print core with non-abrasive filaments without any noticeable downsides.

More on the print core CC Red 0.6

The print core CC Red 0.6 will be available to buy through Ultimaker’s reseller network from November 13, 2018.

With a 0.6 mm diameter, it offers great balance between printing speed and detail. Also, it’s wide enough not to clog easily,which is vital as some of the abrasive materials containing fibers can be really problematic when using smaller nozzles.

Anders and his team recently cut open a nozzle that had printed around 25 kg of carbon fiber and no wear was detectable. To put that into perspective, when printing with common carbon filled materials, brass nozzles typically last for 0.3 kg of printing, stainless steel nozzles for 1 kg, hardened steel for 3-5 kg.

The nozzle on the right shows the wear caused by abrasive filament to a conventional brass nozzle

Users should be aware that ruby can be fragile. As such, it should never be hit with a hard object, and care should be taken when cleaning it. Avoid cleaning the nozzle with a flame as brass easily overheats and deforms which can seriously damage the ruby.

What makes a material ‘abrasive’?

In general, it is best to assume that any filament with a filler (e.g. metals, ceramics, carbon fillers) will cause increased wear, unless the filler is obviously much softer than brass (e.g. wood).

Some are not easy to know, for example glow-in-the-dark filament which has a ceramic powder to produce the glow, which makes it abrasive.

Print core CC Red 0.6 was announced at TCT Show in September, 2018

Using the new print core

Anders is currently testing fillers that stop radiation, that are magnetic, electrically conductive, or can be fired into a ceramic object after printing. His goal is to combine several properties in the same three-dimensional object, which can only be achieved with a dual material printer like the Ultimaker 3 or Ultimaker S5. This requires a reliable print core like the print core CC Red 0.6.

We’d love to hear more about your experiences and plans for printing with composites – join in the conversation here.