Today, May 29th, 2018, marks the 10 year anniversary since the first child of a RepRap printer was assembled by Dr Adrian Bowyer, Vik Olliver, and Ed Sells. Since then, 3D printing has undergone an immense journey – inspiring minds, encouraging collaboration, and influencing the way we think about production. We look back on the role the project played in the career of Siert Wijnia, CTO and co-founder of Ultimaker.

RepRap (short for replicating rapid prototyper) started as an initiative at the University of Bath in England in February 2004. The initial idea was to create an affordable desktop 3D printer that could essentially recreate itself by printing its own parts. The project was started by Dr Adrian Bowyer as a way to make fused filament fabrication (FFF) 3D printing accessible to anyone. At its core, the project is open source, engaging a number of users who continue to contribute to its evolution today. From the hardware to the designs and software, RepRap aims to represent the democratization of production.

RepRap started everything.

On May 29th, 2008, the first instance of a RepRap "child" was created, which was quickly followed by the first printing of a part for a "grandchild". This was proof of the theory that the printers could recreate themselves, marking the first instance of its real-life potential. According to Siert Wijnia, CTO and co-founder of Ultimaker, "From one RepRap printer, you can create two more. Each of those can create two more and so on. Until you have an entire fleet of 3D printers."

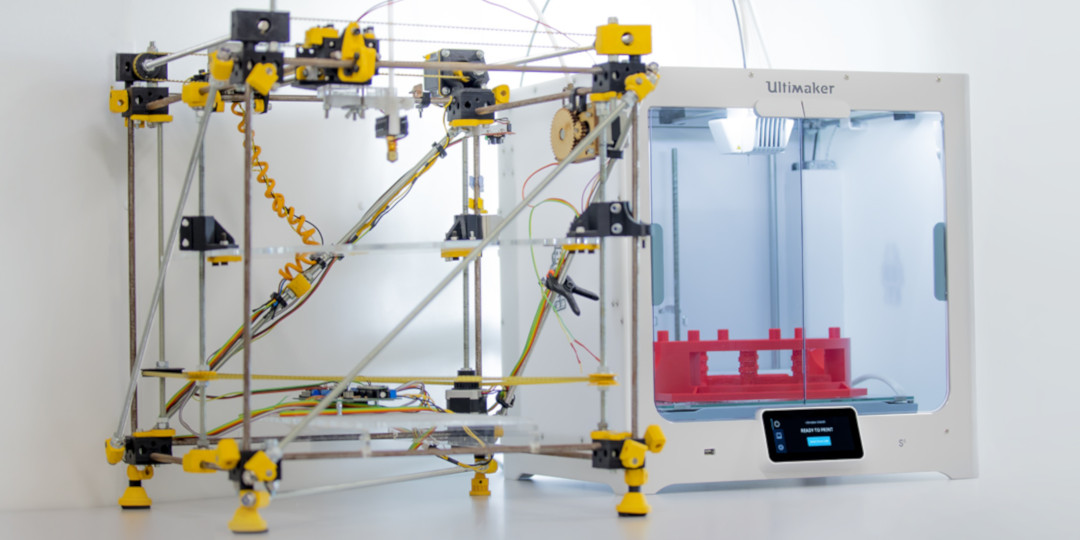

A RepRap Darwin 3D printer assembled by the co-founders of Ultimaker, pictured next to an Ultimaker S5

"The RepRap project started everything," continues Siert. "The price of all the parts – less than €500 – brought it within the reach of the individual. It allowed lots of different people to work together via the internet. There are so many different fields involved – the electronics, the mechanics, the software, the materials. It didn’t matter whether you had a printer or not, you could start working on an aspect of it and contribute to the online community."

3D printing takes off at home and at work

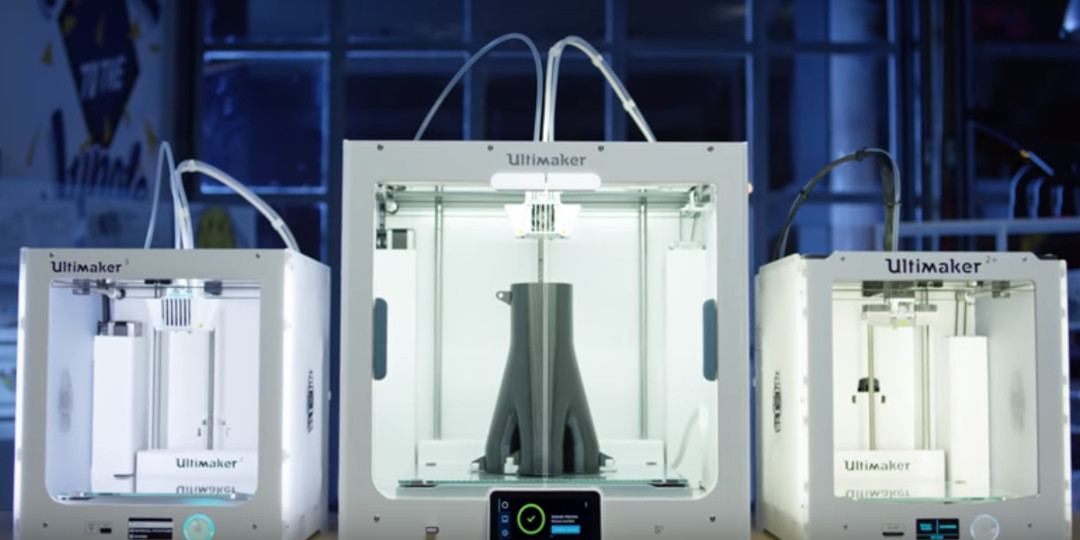

Since 2008, desktop 3D printing has become valuable not only to the home users, but even more so in the workplace. "Researchers are using them for highly complicated scientific studies; engineers are using them to test wind turbines to harness energy. An example we're really proud of is the work of the e-NABLE community, who used our printers to create 3D printed prosthetics. I think that has been interesting – watching people convert energy into something else," says Siert. "They taught us how valuable 3D printing is and made us speed up the process of making 3D printing accessible."

Where is 3D printing going to next?

"I'm convinced that by simplifying the process of creating prototypes, tools, jigs, and fixtures, more creativity will be encouraged," says Siert. "It is not only our task to create an accessible 3D printing experience, but also to present the industry with convincing business cases that underline the added value of 3D printing from an end users' perspective."

The spark that ignited our company.

Siert has huge respect for the project and for Dr Adrian Bowyer. "He gave me the opportunity to get involved and I was lucky enough to be around at the start," he says. "Adrian is a very humble man and put his idea at the center. RepRap was the spark that ignited it all. It was the spark that ignited our company."