Daniel Arellano joined the Bercy Chen Studio over seven years ago, fulfilling a lifelong goal of getting his hands dirty at a design build firm. Today, he’s a Senior Project Manager and oversees design projects for a range of clients—whether they’re 30 and building a commercial space or 70 and designing their dream home.

Building in the heart of Texas

Bercy Chen Studio is located in Austin, Texas, handling commercial projects in and around the city, as well as high-end residential builds in central Texas. With a focus on two key aspects of design and building—construction and architecture—it’s essential that Daniel and his co-workers are able to see site build plans from all angles. In order to achieve this while presenting designs to clients, the team began 3D printing in 2015 to showcase full-scale buildings and wall section models.

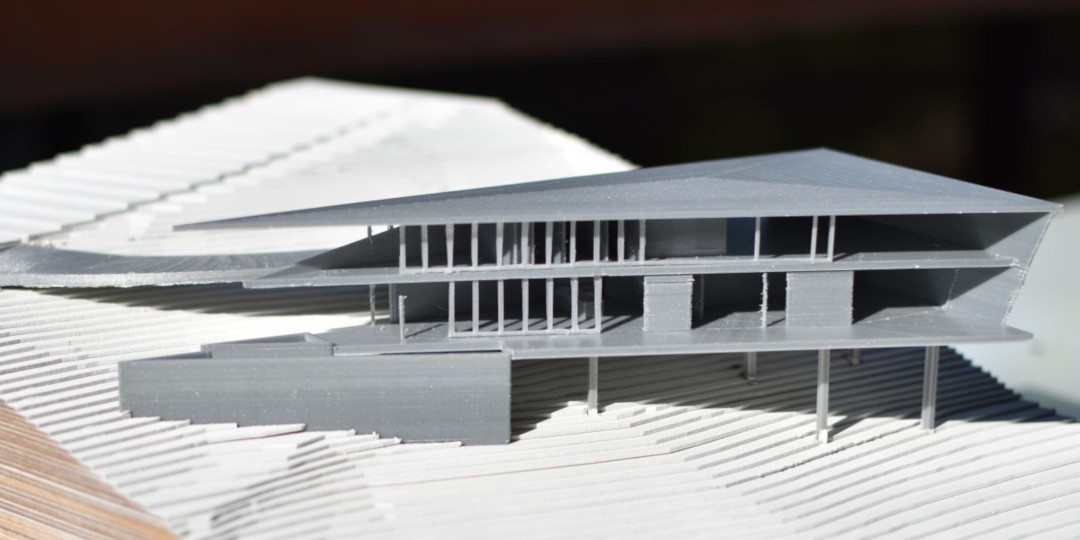

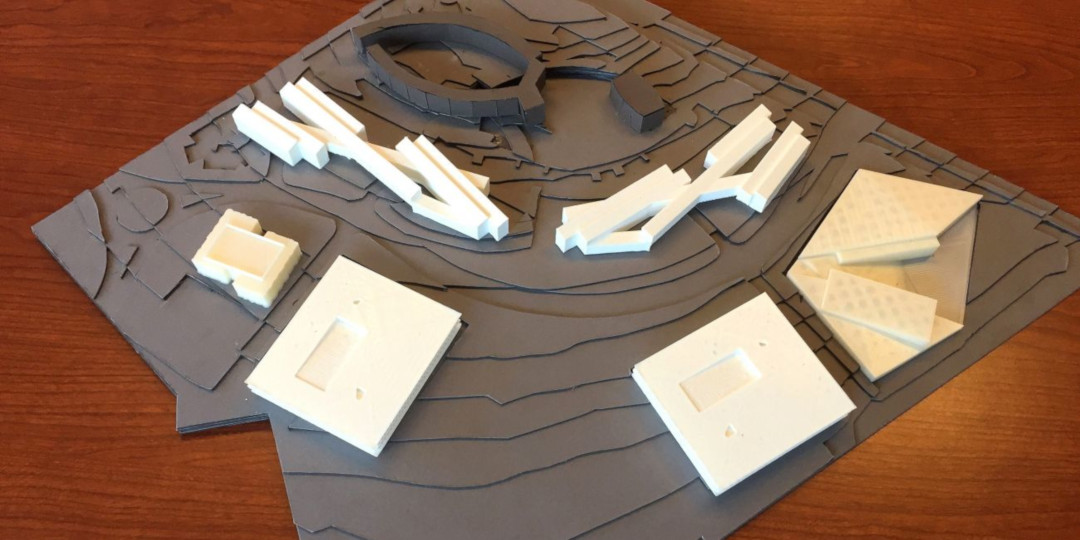

A model of a custom hilltop home in Central Texas

Though they originally purchased a 3D printer to produce designs that would help a client better understand their drawings, the machine remains an essential tool for their processes today. They’re able to mail models directly, show them off in video meetings, or present models in person—effectively clearing up design questions with tangible examples.

Our clients are always giving us great feedback about how much the model helped them understand the project.

Everyone involved enjoys the 3D printed samples, with some clients even requesting to keep their models; though the Bercy Chen team prefers to hold onto them as favorable examples of past projects.

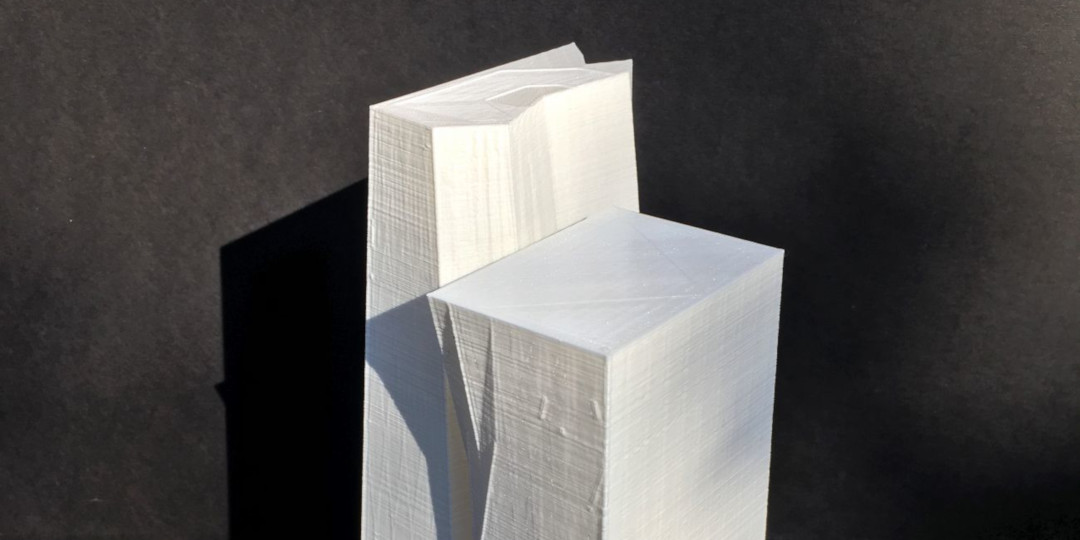

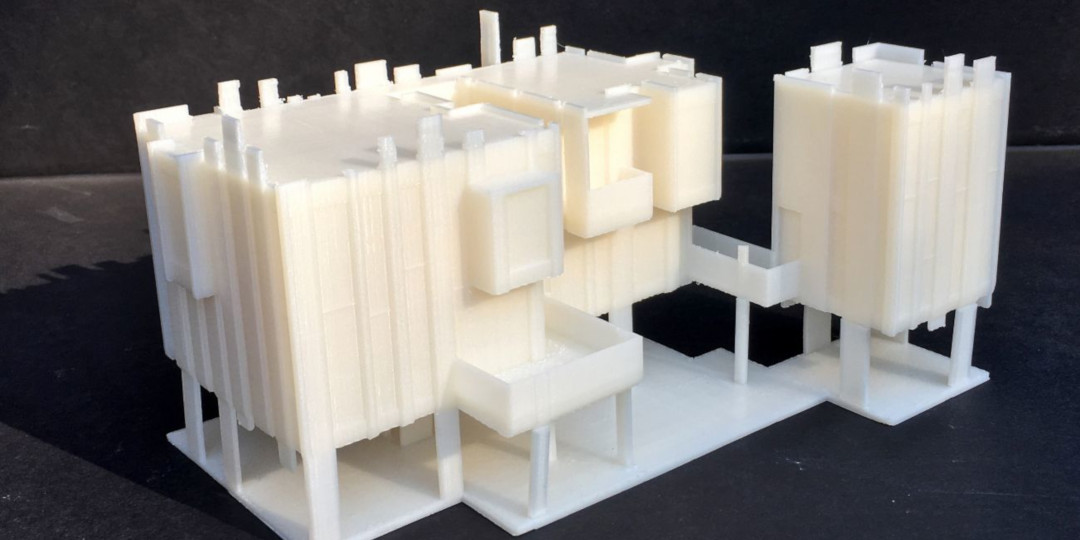

A 3D printed model of a tower in Mexico

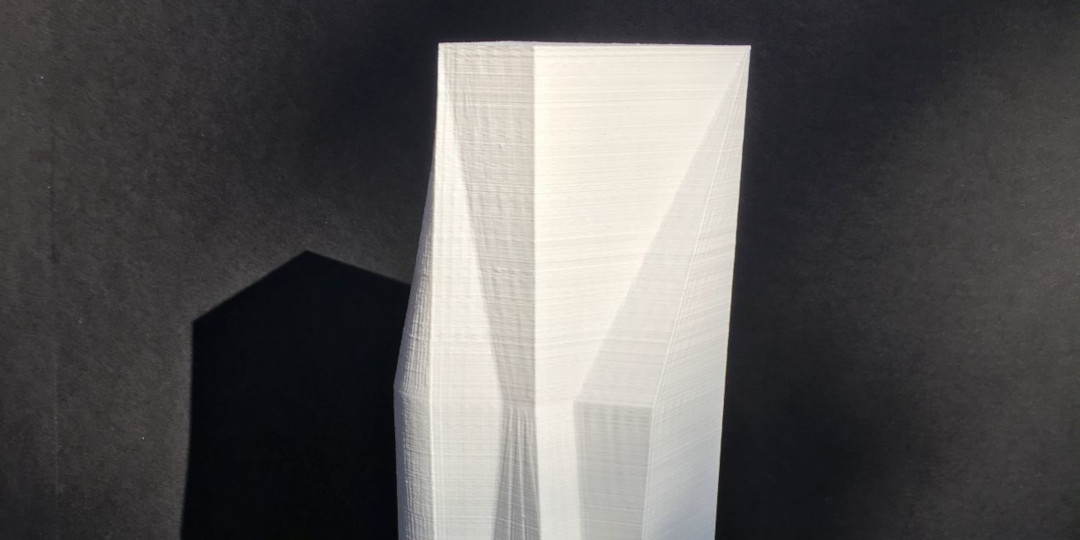

Another 3D view of the tower in Mexico

The models do more than simply provide tangible build site plans. These 3D prints show clients how key architectural features can bring the entire design to life. “They fall in love with the design faster,” Daniel says. “It's almost like a reaffirmation that this can be a real project. It can be built and it can be their home or development.”

A cost-effective design solution

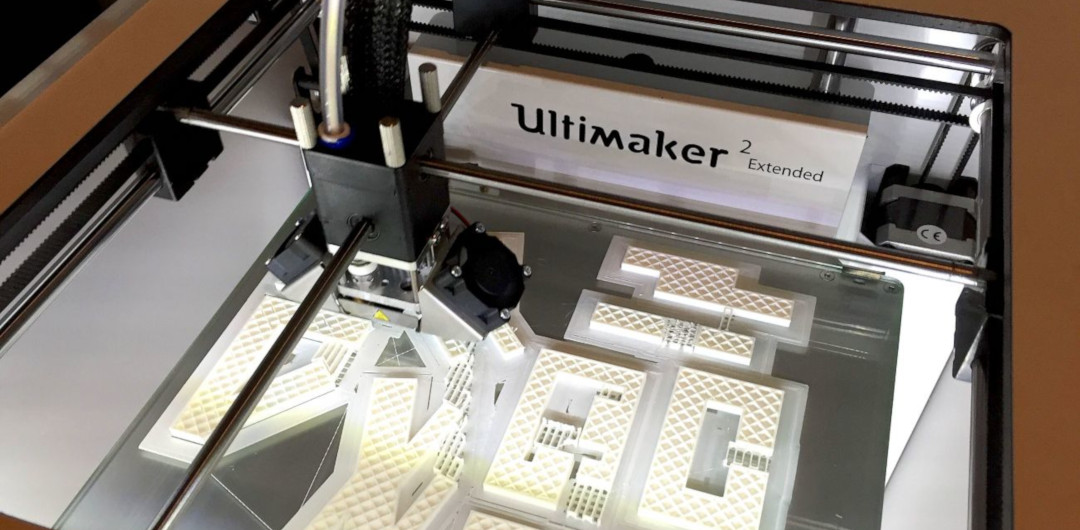

Bercy Chen Studio currently has an Ultimaker 2 Extended on hand, which typically runs once every week for a 24-hour period. When they were in the market for a 3D printer in 2015, the team wanted a user-friendly machine from a company with a solid history of customer interaction. Ultimaker was a clear winner in ease of use, as well as the bonus of an active online community. Now, with nearly three years of 3D printing under their belt, they’re able to get the most out of every design.

We feel that now we don’t throw away any idea. We print and have a physical sketch of that idea that we can all see and share; if we do not end up using that design, it lives on our desk or on the design shelf for a later time.

Discernable advantages of the printer extend beyond impressive keepsake models, however. The easy-to-use Ultimaker Cura software and the quality of their Ultimaker 2 Extended are two important features that have resulted in valuable benefits. “Making a model on the machine is a lot more cost effective than paying someone to make one,” Daniel explains. “Architecture models are expensive and the machine can make a model a lot faster than a person." Since they began using Ultimaker 3D printers, the Bercy Chen team has experienced notable time savings, cost savings, and enhanced productivity all around.

https://community.ultimaker.com/

The Ultimaker also allows their team to print things that would be difficult to hand model, providing greater design flexibility for clients. Such versatility is vital in their design process, which includes modeling tools like Revit, Rhino, and FormIt before they import files into SketchUp and Ultimaker Cura for printing.

Modeling the future of architectural design

To date, one of Daniel’s favorite projects included a large site plan of several buildings that they worked on with two additional architects. His team took the time to print the entire site plan model, complete with buildings from the other designers for a comprehensive presentation. The client was impressed, showing the model to investors and presenting it at a city meeting for site plan approval. Another favorite 3D printing project at the Bercy Chen Studio featured a high-end house perched on the side of a cliff, presenting impressive design and structural features for their client.

A large site plan modeled by Bercy Chen Studio

A high-end house model on the side of a cliff

Daniel feels that other architects can benefit from 3D printing, as it is an invaluable medium for presenting ideas to clients and working through design phases. Creating 3D printed architecture models, he says, gives life to the project that a 2D presentation cannot.

It’s such a great tool for Architects. There is something intangible about holding a design and working on it through model iteration.

In the future, Bercy Chen Studio hopes to print more parts for construction that they can cast themselves, or send to a steel fabricator. They’re excited about evolutions in 3D printing that may bring faster print times, greater resolution, and larger print builds that architects and builders can use to help bring more innovative designs to the table.