What is innovation? We believe it’s all about having the right tool to test your concepts. It’s about troubleshooting and communicating ideas quickly, easily and coherently. Read on to find out how we developed the Ultimaker 3 – using our very own Ultimaker 2+ printers.

3D printers open up a world of possibilities. They let product designers and engineers test, evaluate and improve their ideas. Even more importantly, they’re a powerful tool for professional applications and can be used by anyone. By making professional 3D printing more accessible, we enable engineers, manufacturers and many more people to enjoy greater dimensional freedom. The Ultimaker 3 is the perfect example of this in action.

How was the Ultimaker 3 made?

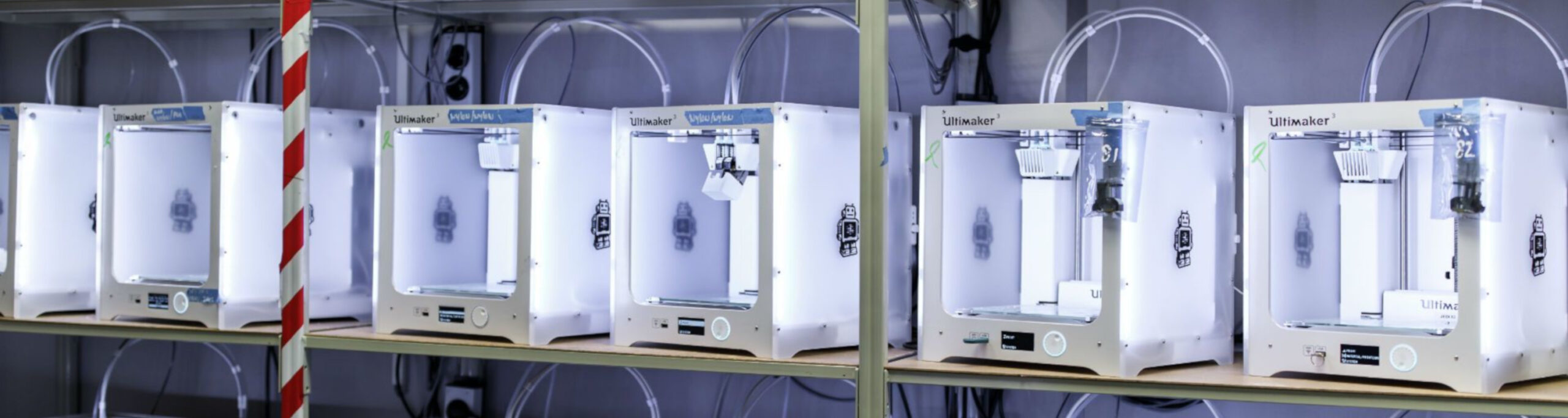

The latest Ultimaker printer was created using our own Ultimaker 2+ machines! Throughout the development process, Jan Oosting (one of our lead engineers) and his team used our existing 3D printers to evaluate designs, create functional prototypes, test assembly and feasibility, as well as troubleshoot and create customized tooling.

This saved us over 4 months of development time and over 20% in R&D hardware development costs – proving just how effective and powerful 3D printing can be.

Validating and testing

Jan Oosting, R&D engineer at Ultimaker

As an engineer, you ideally want to test your ideas at a very early stage, and thanks to this flexible process there are more opportunities to remove risk of failure from your design. This leads to an end-product that’s far more reliable, not to mention more cutting-edge.

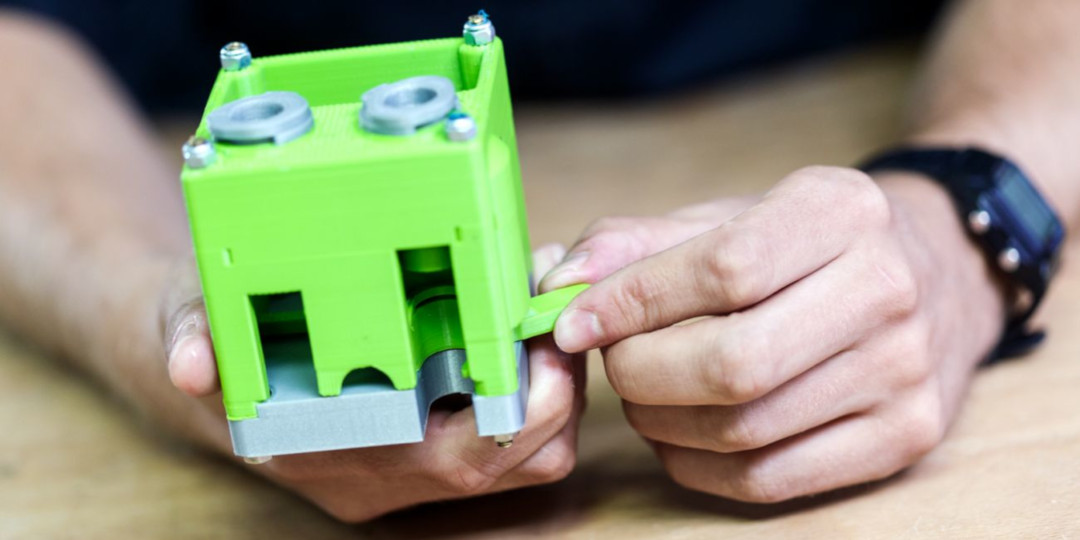

With a 3D printer, you can communicate your ideas to the team and validate the designs incredibly quickly. Take the Ultimaker 3 print head. Our R&D team could evaluate the 3D printed prototype designs, fine-tune the aesthetics and envision far more easily how people would interact with the print cores.

After performing the conceptual study, you can dive deeper into design details and explore how the parts will be assembled, fit and work together. It gives you the chance to test several concepts at the same time (at almost no extra cost) and validate the design before going into production. Just as importantly, you can do this in-house, which saves time in terms of waiting and negotiating. It goes without saying that it also saves a lot of money if you eliminate the need for 3rd party vendors.

Functional prototyping

When it came to functional prototyping, using Ultimaker 2+ printers for the development of the new Ultimaker 3 was invaluable. “For example,” Jan told us, “we could easily create scaled-up versions of the necessary parts. Without a 3D printer we would have skipped this important analysis, because it would be too much hassle to arrange the prototypes and justify the external costs.”

The idea might look great on paper, but without a tangible model, there’s no way of testing to see if it really works in real life. Therefore, functional testing is crucial, and with 3D printing you can do it at least two times faster. You can check several concepts at the same time, and test how everything fits together before ordering the injection-molded parts.

We used 3D print prototyping to put different designs to the test; checking the stress relief on the print head cable, not to mention testing how reliable they were, and how easy to use.

Greater efficiency

One of the greatest advantages of using the Ultimaker 2+ machines to develop our product was the time we managed to save. Our team could swiftly verify the best design concept, discuss ideas, and do iterations without running up a significant additional cost.

“Normally it would take weeks to test each new concept,” Jan informed us, “but with the Ultimaker 2+ we could significantly optimize the process. We could design a few new prototypes, print them overnight and test several dimensions the very next day.”

The Ultimaker 2+ machines were also useful in the later stages, enabling the team to test functional models. The first Ultimaker 3 prototypes of the reel holder and filament guides were printed on the Ultimaker 2+. “The prototypes of the filament guide, for example, helped us test the feasibility of different concepts, to see if we could solve the entanglement problem. That was extremely helpful for us.”

Troubleshooting

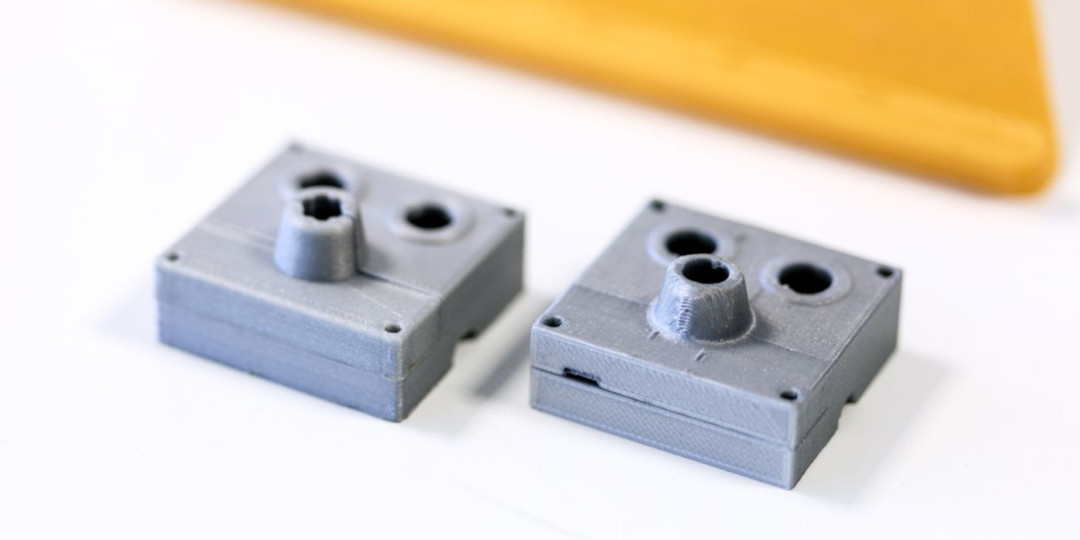

In addition to testing and prototyping, our Ultimaker 2+ printers proved to be ideal for troubleshooting issues. For example, one of Ultimaker 3’s unique features is the swappable print cores. For this feature to work properly, the nozzle placement has to be precise. While road-testing this function, we had a few issues with layer shifting.

We printed scaled-up models of the bottom plate, then added some ink where the nozzle touched it. This let our team get a feel for the problem, and develop a range of different possible solutions (introducing lower torque on the screws to make the bottom plate flatter, which ensured the conical parts lined out better). We also added a steeper slope, ensuring the positioning force was higher at the center.

Tackling the layer shifting issues with 3D printed scaled up parts

Custom tooling

Additionally, our team used Ultimaker 2+ to 3D print custom tools, which resulted in easier, faster assembly. Jan elaborated: “Without tooling, you had to use pliers to push down the capacitive sensor into the fan bracket. It was really difficult, and took a lot of time to do it properly. To solve the problem, we simply used the Ultimaker 2+ to create a stapler. It saved us loads of time in production.”

It’s also worth mentioning that manufacturing aids offer great ROI. You can 3D print the necessary custom tool in a matter of hours and spend about $10 in material costs. This is a huge difference when compared to popular traditional production technologies.

Better communication

All our engineers agree that 3D printed prototypes are vital when it comes to communicating ideas within the entire company. “It’s easier to get approval from the management board,” Jan told us, “as they can see the part in action. We can also prove it’s reliable, effective and easy to manufacture before committing to production.”

Some of the brilliant people behind the Ultimaker 3

Making of the Ultimaker 3 was an incredibly exciting project and we want to thank all the amazingly talented people who helped us make this happen!

This is a real-life example of how 3D printers help you innovate – to test and explore new designs, and to offer an even better end-product. It’s all about communicating, collaborating and improving. We believe, with the right tool, there are no creative limits, only endless ways to make a real difference. The future's in the making. Now it’s your move!