Forward-thinking professionals all over the world, from designers to engineers to architects, discovered that the Ultimaker 3 is a powerful, low-cost solution that significantly streamlines production processes and concept development. Building on the capabilities of the Ultimaker 3, the Ultimaker S5 adds enhanced performance with a larger build volume, effortless operation, and unparalleled reliability.

The Ultimaker S5 is here

We are proud to announce our most advanced 3D printer yet – the Ultimaker S5. Built for the office, the Ultimaker S5 is a powerful, reliable, and versatile 3D printer that delivers industrial-class results.

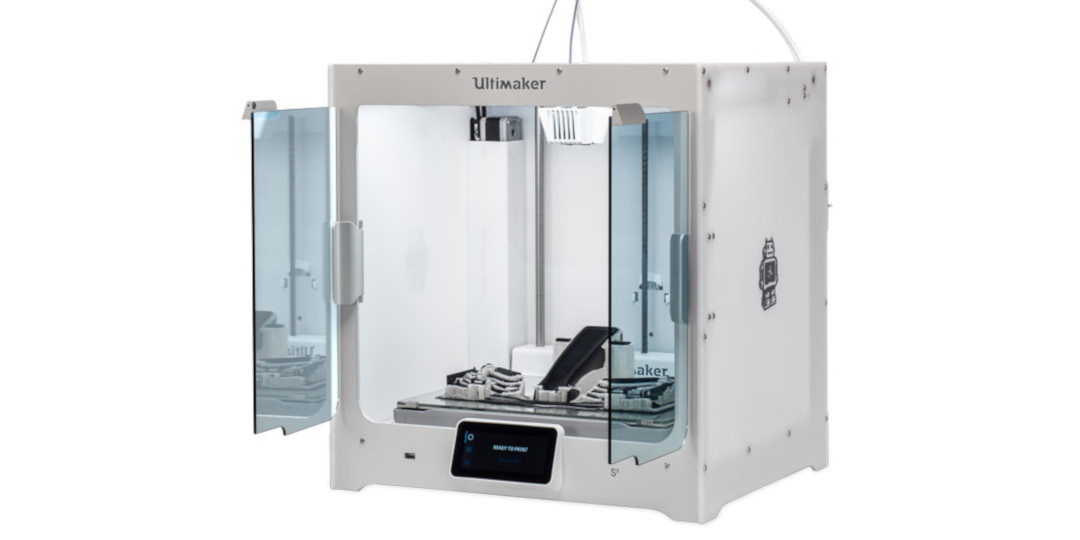

Function with form

The Ultimaker S5 packs powerful technology in a simple, clean, stylish enclosure that fits right in with your office. An enclosed front, with tinted glass doors, ensures that the internal temperature and airflow are optimal. An intuitive touchscreen interface guides you through operation of the printer, and displays detailed status information. Frame lights provide visual feedback, and project clean white light to overview and inspect your print up close. And an embedded power supply gives the printer a clean footprint, making it ideal for shelf or rack mounting.

Reliability at scale

The Ultimaker S5 has a large build volume of 330 x 240 x 300 mm. Print at large scale, or fit multiple parts on a build plate, so you can get the dimensions you designed for. And in combination with our remote 3D printing software, group multiple Ultimaker S5 and Ultimaker 3 printers together to maximize production efficiency.

Reliable adhesion, from first layer to finished part

A perfect first layer is crucial to every 3D print. To ensure that this happens every time, we have overhauled our active leveling technology. The Ultimaker S5 probes the build plate in a greater number of locations, creating a precisely detailed heightmap of the build surface. Using this data, it compensates for any surface deviations in real time, giving you a perfect, ultra-flat first layer, with secure adhesion that lasts the entire print. There’s no need for constant monitoring - just start a print, and leave the Ultimaker S5 to do its job while you do yours.

High uptime and greater flexibility

Swappable print cores enable effortless, tool-free maintenance and maximum printer uptime. Achieve different print characteristics using different nozzle sizes, ranging from 0.8 mm for rapid prints, to 0.25 mm for ultra-fine detail. With two available print core slots in the print head, quickly and easily click in your desired combination for reliable dual-extrusion. Print with different colors for aesthetic impact, or use water-soluble PVA or Breakaway support for full geometric freedom, easy post-processing, and a high-quality surface finish, so that tactile presentation models, or complex mechanical parts look polished and professional.

To keep your print securely in place for the entire print duration, the Ultimaker S5 uses a large hardened glass build plate that quickly and easily clips onto an extra-stiff cast aluminum heated platform.

Full control at your fingertips

A responsive, full-color touchscreen, integrated into the front panel of the Ultimaker S5, makes operation intuitive, effortless, and informed. Swipe through menus and tap options to select them, just like a smartphone. Detailed information, such as loaded materials, print cores, and the build plate and nozzle temperature keeps you up to date about jobs in progress, and a 3D preview lets you see what’s printing at a glance. And with eleven supported display languages, including English, German, Simplified Chinese, Japanese, and Korean, the Ultimaker S5 is accessible to users all over the world.

Never used a 3D printer before? No problem. The touchscreen intuitively guides you through setup and maintenance operations, using simple, easy-to-understand language, complete with high-resolution images, so that everything is crystal-clear, regardless of your technical abilities.

Get ahead with professional prototyping

A Bowden extrusion system keeps the print head ultra-light, for the fastest possible performance. A tight filament path ensures a reliable experience printing with flexible materials, such as TPU 95A.

Material is moved at a precise rate with a tool steel feeder gear, with an extra-hard coating to prevent long-term wear. And the redesigned silicone nozzle cover keeps print head airflow consistent, for efficient material throughput.

Loading, unloading and changing material is effortless, with an ergonomic locking lever built into each feeder. Flip the lever upwards to manually insert or remove material. Flip it closed, and constant force is applied to the material, so it is driven accurately.

A built-in filament flow sensor intelligently detects when material stops moving or is nearing an end. To save your print if a material runs out, the Ultimaker S5 will automatically pause and prompt you to take action.

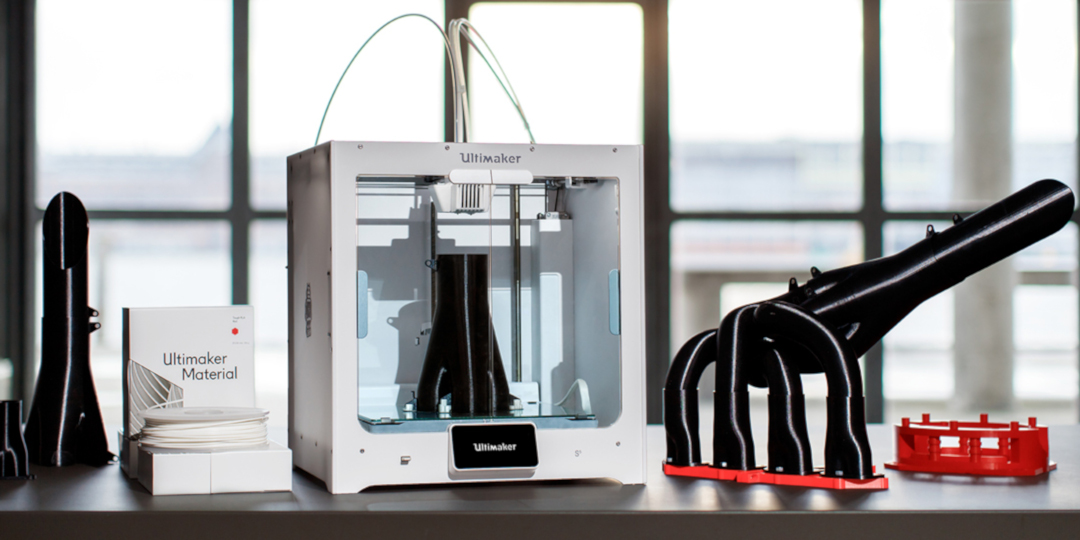

Engineering-grade materials, for a diverse range of properties

The Ultimaker S5 supports the full portfolio of Ultimaker materials, including ABS, CPE+, Nylon, and TPU 95A. A 750 g spool of our newest material, Tough PLA, is included in the box of each Ultimaker S5. With high impact strength and stiffness, but with the easy and reliable printing experience of PLA, Tough PLA has mechanical properties similar to ABS, making it a great material for large functional prototypes, tooling, or manufacturing aids.

A smart spool holder conveniently clips on to the back panel of the Ultimaker S5, and accommodates two separate 750 g material spools. Load a spool onto the holder, and using the holder’s built-in NFC reader, the printer will recognize the Ultimaker material type, and automatically select the optimum printer settings, so you don’t need to.

Our team of material experts has performed rigorous testing on each Ultimaker material to ensure maximum compatibility with the Ultimaker S5, as well as optimizing over 200 settings in Ultimaker Cura, our free print preparation software, to create material profiles. Use material profiles to prepare your prints, and take the guesswork and experimentation out of 3D printing, achieving high-quality results the first time around. And if you want to experiment other materials, our open filament system lets you use third-party materials with ease.

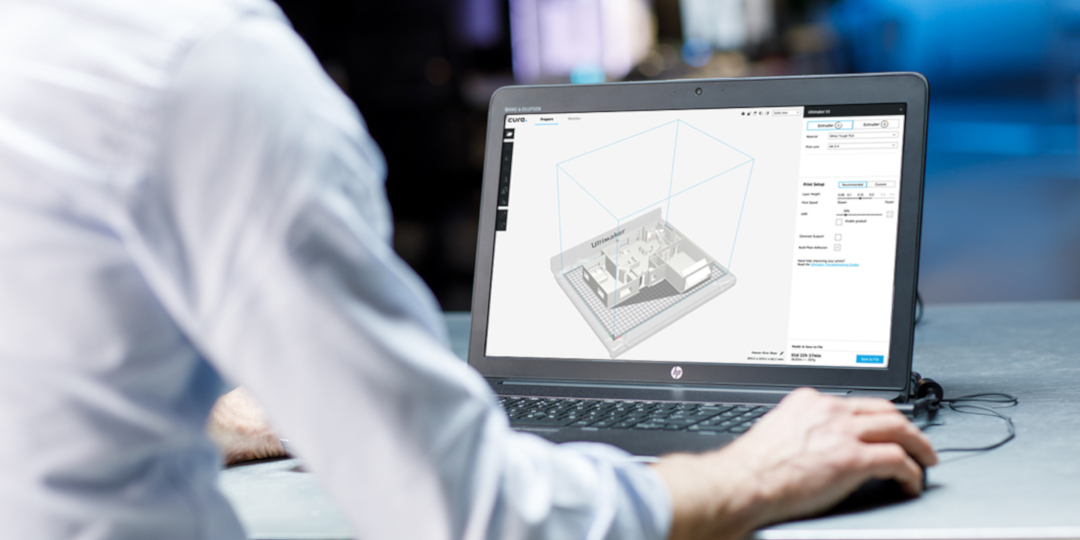

An end-to-end workflow, ready for the future

Make 3D printing a smooth process by using an integrated ecosystem of software products designed to work seamlessly with each other.

With high speed Wi-Fi and LAN connectivity built directly into the Ultimaker S5, regular firmware updates, with new features and improvements, will enhance the printer’s capabilities over time.

Ultimaker Cura ensures a seamless workflow. Prepare prints, send them to the printer wirelessly, and monitor jobs remotely using the printer’s integrated camera. Learn more about Ultimaker Cura.

Get a mobile overview of each running job with the new Ultimaker app. Manage and monitor printers, and receive notifications on the go—even outside your local network.

Get ready for the most powerful Ultimaker yet

The new Ultimaker S5, Tough PLA, and the new Ultimaker app are available from May 15th 2018. Localized, certified support is included with every purchase.