Pioneer Joshua Pearce explains why educators (and everyone else) should always consider using free and open source options in and out of the classroom.

Three reasons for open source tech in your 3D printing classroom

Joshua M. Pearce

Department of Materials Science & Engineering

Department of Electrical & Computer Engineering

Michigan Technological University

Although educators should always consider the use of free and open source software (FOSS) for education, the preponderance of evidence shows that in the area of 3D printing/additive manufacturing the case for FOSS is clear. Three reasons you should only use an open source toolchain in the classroom to teach 3D printing include:

1. History: Open source is the only reason you have a 3D printing class at all

3D printing is actually a pretty old technology. It goes all the way back to the 1980’s. Unfortunately, it was locked away with intellectual property for 20 years with only a few lucky well-funded people able to access it (in the old days the only available 3D printers cost hundreds of thousands of dollars). That all changed with the open sourcing of the RepRap (self replicating rapid prototyper) 3D printer after the overly-broad patent on all fused filament printing expired. The RepRap project’s goal was to make a 3D printer that could print itself.

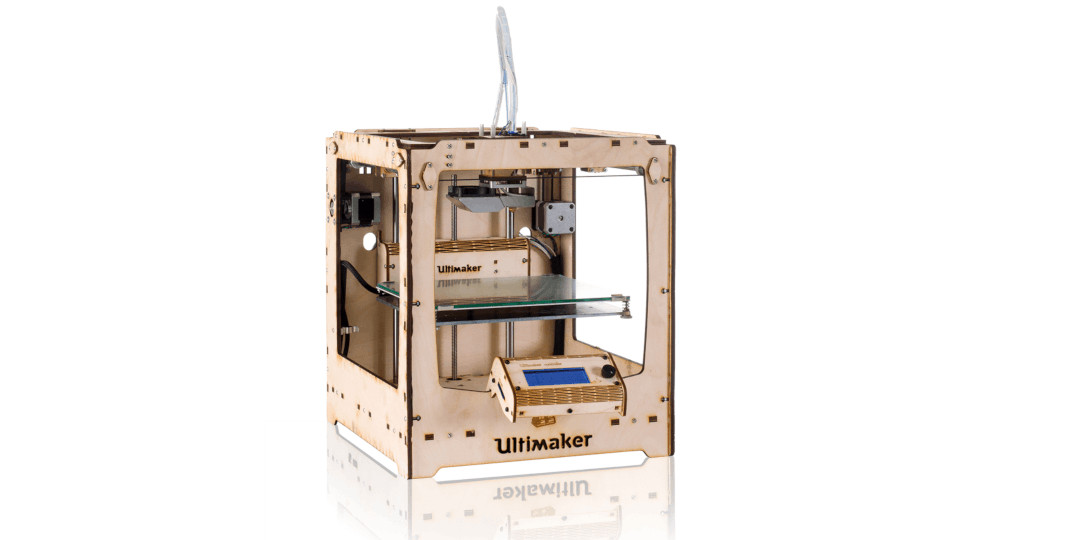

RepRap is an open source hardware project licensed under an open source license, which means that over the last decade or so, hundreds of innovators all over the world have been improving RepRap technology: both hardware and software. The open sourcing of the RepRap has led to dozens of 3D printer companies including Ultimaker (see source files) that used the RepRap designs as a foundation to jump-start their own products. As you know, now there are many affordable high-quality 3D printers that make excellent educational tools at every academic level. To remain consistent with the spirit of that development and to avoid unethical coercion and forced dependency of your students on proprietary software, you should utilize an open source toolchain.

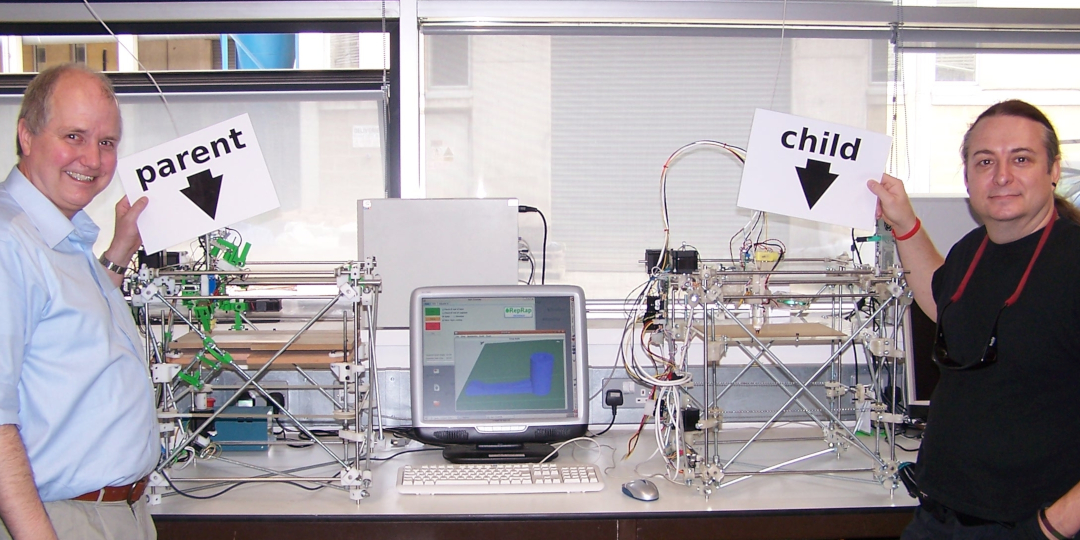

Adrian Bowyer (left) and Vik Olliver (right) with a parent RepRap machine, made on a conventional rapid prototyper, and the first complete working child RepRap machine, made by the RepRap on the left. The child machine made its first successful grandchild part at 14:00 hours UTC on 29 May 2008 at Bath University in the UK, a few minutes after it was assembled. (https://reprap.org/wiki/About)

Ultimaker Original open source 3D printer

2. Cost: $0

It is not only the hardware in 3D printing that can be free, but also the software. The “free” in FOSS refers to software that respects your freedom. Thus it means that the users have the freedom to run, copy, distribute, study, change, and improve the software. In the context of 3D printing software it also means that because you have access to the source code and the freedom to use it, the software is free - i.e. cost of $0. This has an obvious benefit as it reduces the cost of your 3D printing program at your school. However, the benefits also extend to your students. They can download the software for free at home, so they can practice or work on their projects at home without purchasing expensive licenses. The benefits extend into the future as well. After your students graduate from your school, they will be able to freely open and edit their own work and build upon it. This is not true of most proprietary packages. They may get educational discounts now (or even freeware), however, when they graduate this is rarely true.

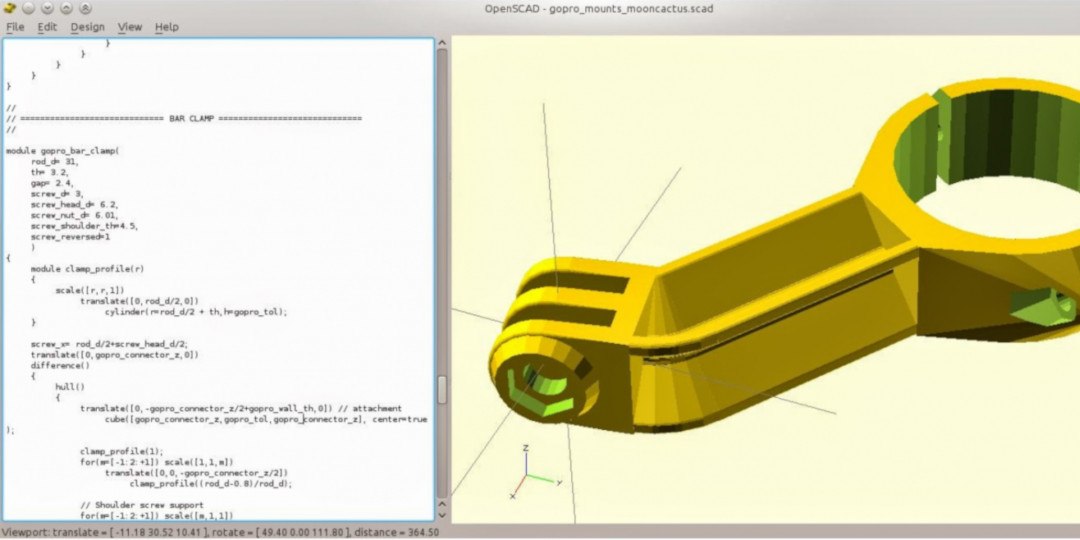

For example, 3D printing design normally begins with CAD (computer aided design). A typical proprietary CAD package like Autodesk’s Autocad costs $1,400 per year! At Michigan Tech for our award winning 3D printing class we use three FOSS CAD packages. First, we use OpenSCAD, which is a script based CAD package for students that are already familiar with computer coding and because it is extremely powerful at parametric designs. For students more familiar with conventional CAD packages, there is FreeCAD. Finally, for students with more of an artistic bent, there is a free 3D modeling program called Blender, which was originally meant to help make 3D movies, but also makes for an aesthetically pleasing 3D printing design tool.

With all of these FOSS CAD packages it will make it easy for you and your students to share designs on websites like YouMagine. Then rather than others only be able to customize the STL files with significant effort, they will also be able to use your source files with free software to improve upon the design. This creates a technological evolution, which can pay dividends to your students for sharing their designs.

Example of OpenSCAD for 3D printing.

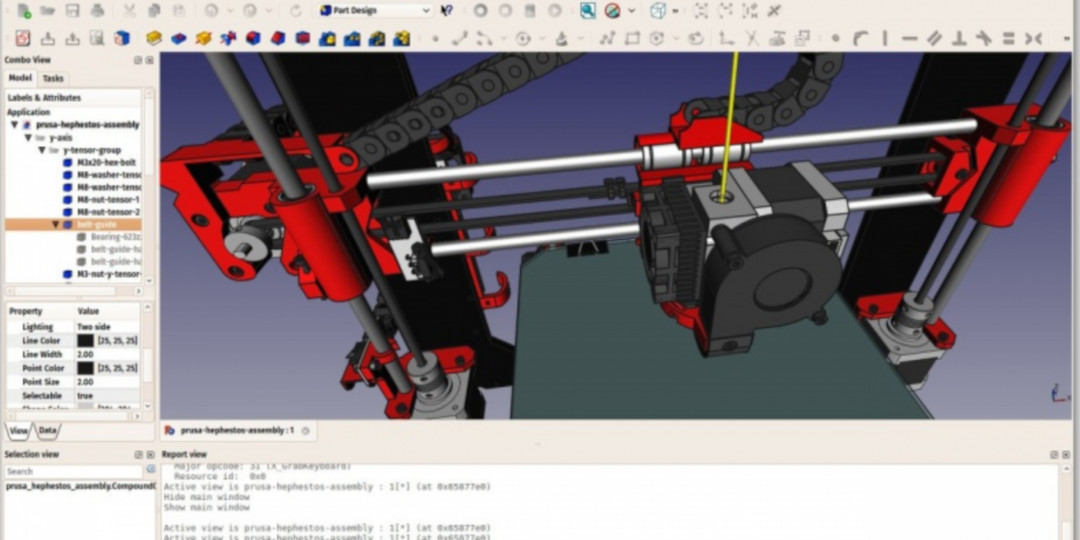

Example of FreeCAD for 3D printing.

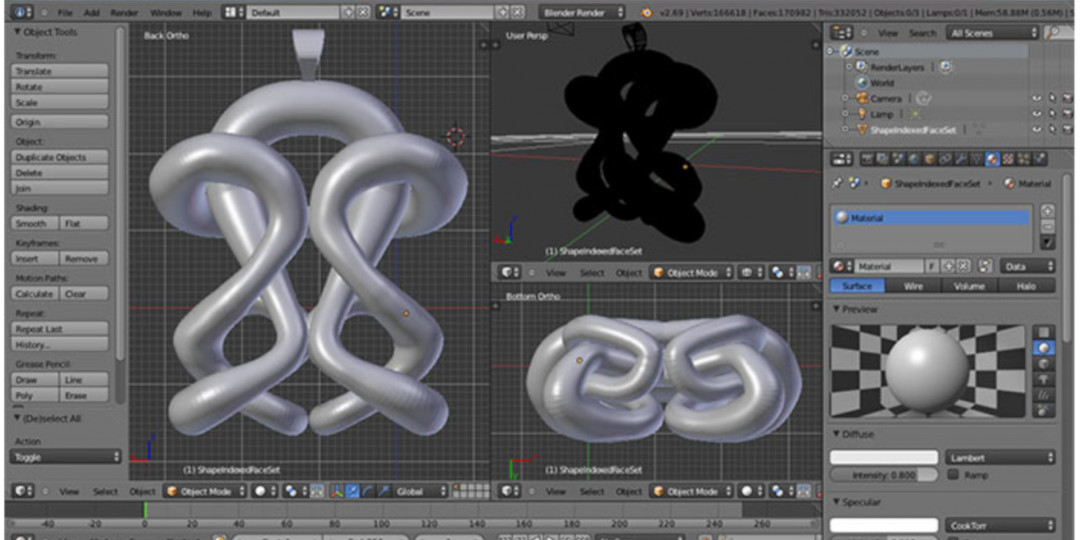

Example of Blender for 3D printing.

Next you need a slicer to break your 3D model into 2D slices of toolpaths for your print head. There are several excellent FOSS options available including Slic3r and Cura. Next you need a print controller if you do not use the built in version in Cura such as Printrun or Franklin. It is absolutely possible to completely run a 3D printer from start to finish using only FOSS.

3. Control: You are never held hostage

If you use FOSS and FOSH you always have control over your 3D printing tools. With access to the code you always have the ability to continue to work with the software. If you are reliant on commercial proprietary software you are beholden to the companies that own it. This means you could literally lose control of your own 3D printer if you go the closed-source route.

Your 3D printers could be held for ransom or simply cease functionality completely if proprietary vendors no longer offer support for their products due to a litany of reasons including:

loss of key technical staff,

planned obsolescence of equipment to sell new models (or software)

ends a product line,

stopped supporting software to run their old hardware as operating systems change with time,

they have canceled making specific products or components, or

in the worst case, simply gone out of business.

In addition, if your 3D printing vendor is bought by another company that changes policy or price, with a proprietary technology you have no control. With FOSS and FOSH your equipment can never be held ransom. You truly own it - which means you can fix it (or pay someone else to), improve it, upgrade it, and use it indefinitely. Best of all, so can your students - so what they learn in your classroom they can take when they graduate. You and your students only have this kind of control with free and open source technology.