Urban Scale Interventions (USI) is a design studio that delivers people-centered innovation to private and public organizations.

When commissioned to transform seven forgotten sites in Belfast, Northern Ireland, the USI team turned to 3D printing to create a lighting experience that draws inspiration from local history.

Their largest, award-winning installation at the "Winecellar Entry" has transformed the space outside the city's oldest tavern, Whites. What was once a hub for antisocial behavior has become a tourist hotspot and one of the most photographed parts of the city.

To kick off the project, the USI team brought the community together to inform every decision made. In a series of public workshops, they surveyed over 1,500 residents to answer one question:

How would you use lighting to bring a sense of belonging or hope to a city?

Four co-design principles came to light from the answers – to create experiences that were "sustainable, playful, interactive, and safe".

3D printed using Ultimaker, their (now award-winning) installation would create a focal point that illuminates one of the hidden gems of Belfast's rich merchant history.

People-first design

Ralf Alwani, Co-Founder of USI, chose to explore FFF 3D printing following the start of the pandemic. The technology gave his team the ability to control every aspect of the design and production process in-house.

"It gives people like us who aren’t advanced manufacturing experts an opportunity to get into the process of design-to-manufacture."

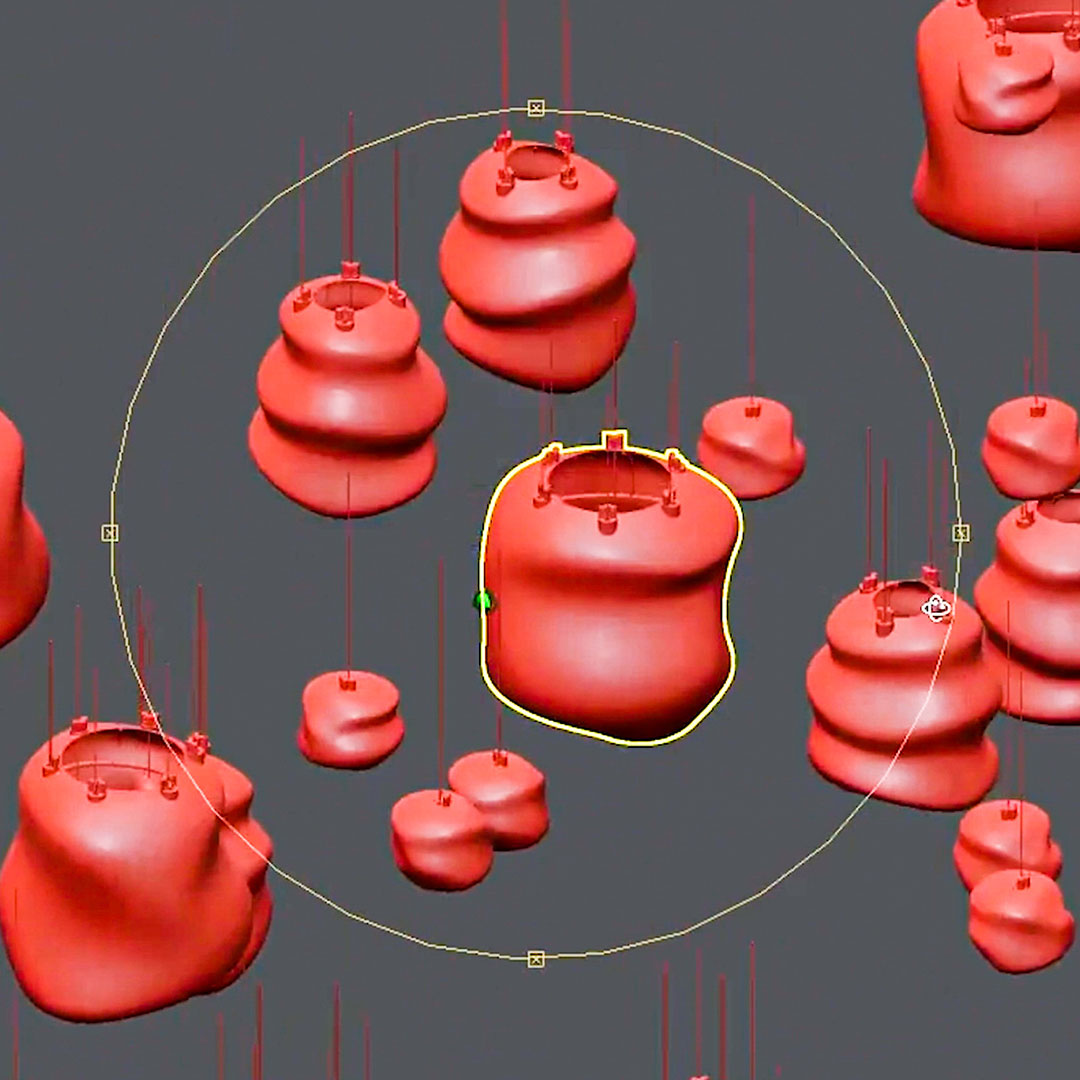

The team quickly realized other benefits. With the ability to visualize the entire installation in 3D using CAD, they gained the flexibility to test sculptural ideas and then easily translate those designs to the 3D printer. This production process wasn't just faster – it effectively negated human error in comparison to traditional model-making.

Art Director, Greg Edwards, elaborated, "For us it was a whole new organic design process. We were able to literally take these objects from the design table to the street."

But what exactly are these objects?

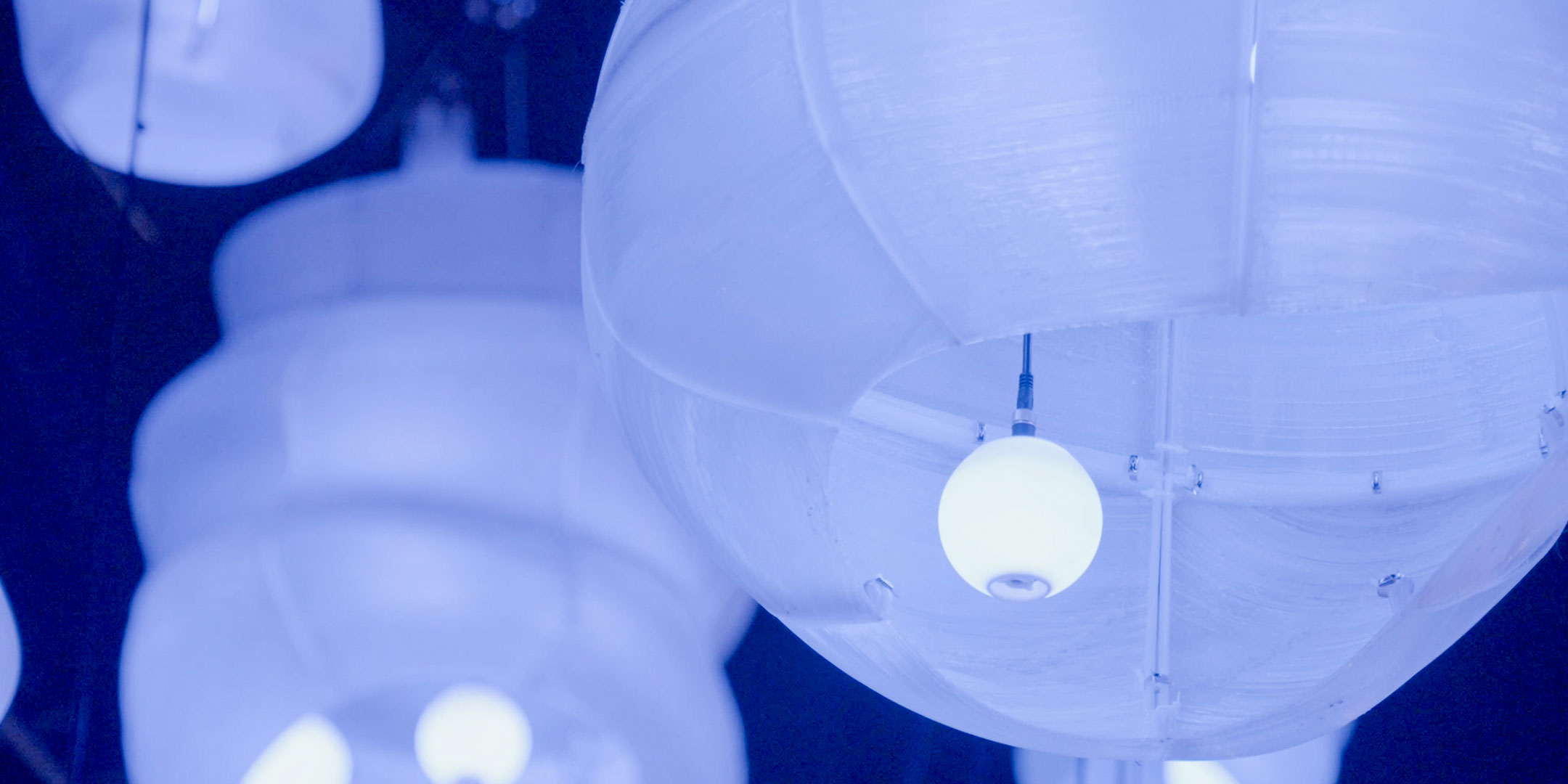

An ocean of floating orbs

After testing different forms, the team finally decided on an evocative "ocean orb" design. This links to Belfast's maritime heritage and the location's history as a fish market.

The designers could visualize the entire installation in 3D

Then transfer files to the 3D printer to validate the design

The team created iterations quickly on site allowing them to explore more design options. Alwani explains:

"We could constantly change parts, adapt them, and use them in a way that improved our design. The ability to experiment throughout the making process completely changed the output of the product."

There are 43 orbs in total, in 3 sizes. Because even the smallest size was too large for the 3D printer's 330 x 240 x 300 mm build volume, the orbs were 3D printed in sections. The small sizes had 3 sections and the larger size had up to 15 sections. All in all, roughly 450 sections had to be accurately 3D printed within a tight deadline.

Deadlines despite COVID

The workhorse machines chosen for this big challenge? Three Ultimaker S5 3D printers.

"With the Ultimakers working in the background, it was almost like having an extra pair of hands. This allowed us to progress other aspects of the project," said Project Architect, Lorna McCarten.

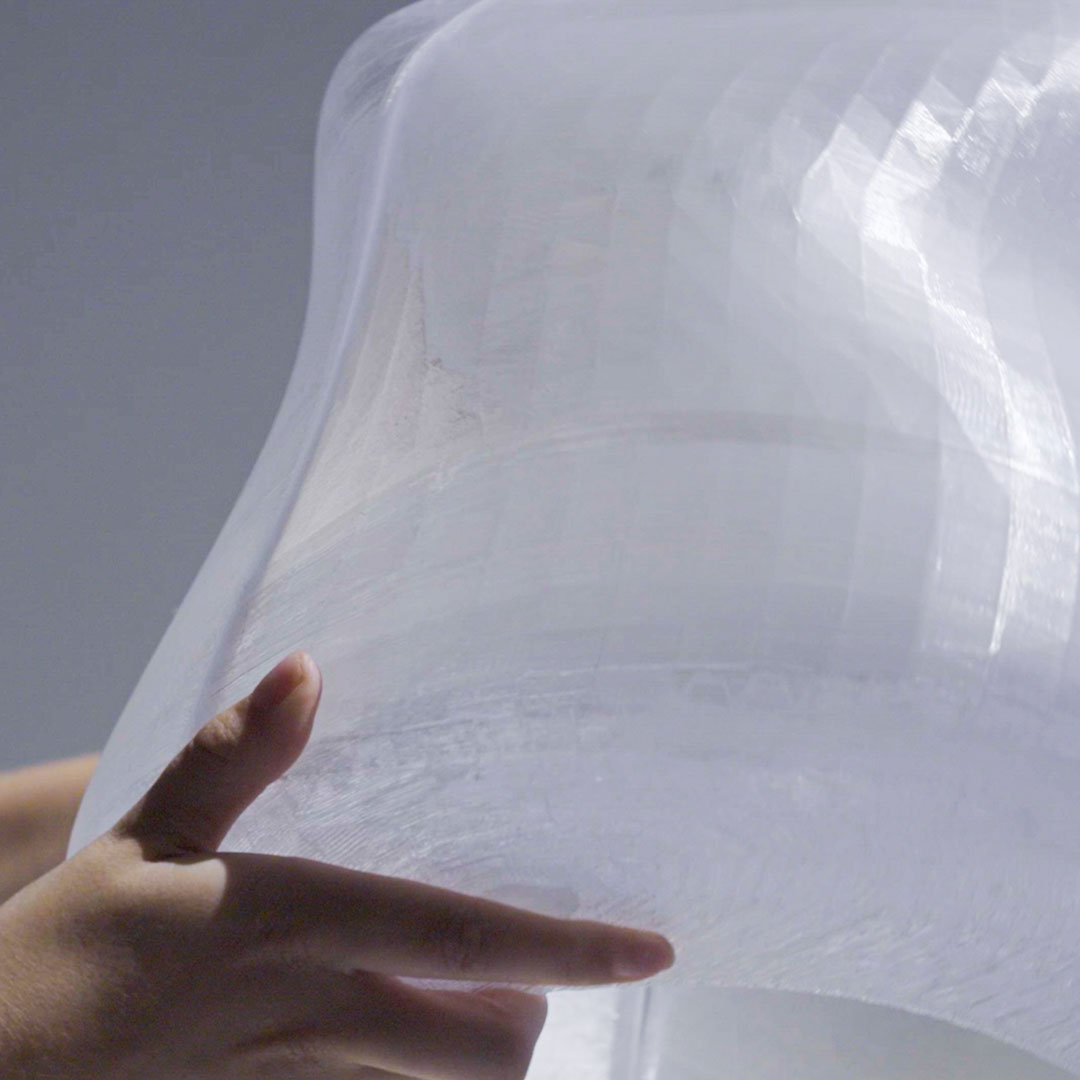

The orbs were 3D printed in up to 15 sections each, using a transparent PETG made from recycled plastic

This manufacturing flexibility was crucial when a new wave of COVID restrictions threatened to delay the project. The team had been working out of an old linen mill in the center of Belfast. But the compact, modular nature of the Ultimakers meant production could continue. Alwani said:

"The ability to set the Ultimaker S5 up anywhere was really handy. When lockdown came, we moved to the spare room in my house because we had a deadline to meet and there we could continue manufacture."

And when that deadline arrived, the USI team found that 3D printing had enabled an intimacy with the project in a way they never expected.

Graphic Designer, Rosanna O’Kane, said: "3D printing allowed our team to be hands-on every step of the way. From design to fabrication to installation. So we knew everything about the project and could problem-solve more easily along the way."

Despite COVID lockdowns, the team met their install deadline thanks to 3D printing's flexibility

The team could be involved in every step of the project – from design to deployment

Simple, sustainable material

As well as reducing environmental impact with local manufacturing, USI went further to pursue their principle of sustainability.

They chose to 3D print the orbs using Filamentive's Translucent PETG (its click-and-print settings are available on Ultimaker Marketplace). Wound on a cardboard spool, up to 89% of this filament is made from recycled material – plastic waste that would otherwise go to landfill. For every 1 kg of material sold, Filamentive also plants trees to offset at least 1 kg of CO2.

Using only a single translucent material meant that the bulbs inside each orb could dynamically change color in harmony with a soundscape specifically composed for the installation.

The overall effect created a new sense of place and an instantly "Instagrammable" experience for visitors to share.

Urban Scale Intervention won a Placemaking Award for the Wine Cellar Entry installation

A brighter future for Belfast

And the timing could not have been better. The installation didn’t just transform the site into a destination that people can explore and enjoy. It has also given back to the hospitality industry – one of the sectors hardest hit by COVID.

With USI's work opening the eyes of more people about the possibilities of additive technology, Alwani sees a positive outlook for the city's creative community:

3D printing offers a new and accessible way to put manufacturing back in the heart of young people in Belfast, who aspire to design and reimagine the future.

Want to discover more? Read the 6 reasons why every architect needs a 3D printer. Or download the free white paper below.

This story is based on content originally created by Ultimaker partner, Ultimaker GB.