Ecosystem of additive manufacturing

Additive manufacturing technology requires an entire ecosystem around it to function efficiently. Below are the four components of the ecosystem.

CAD and slicing software

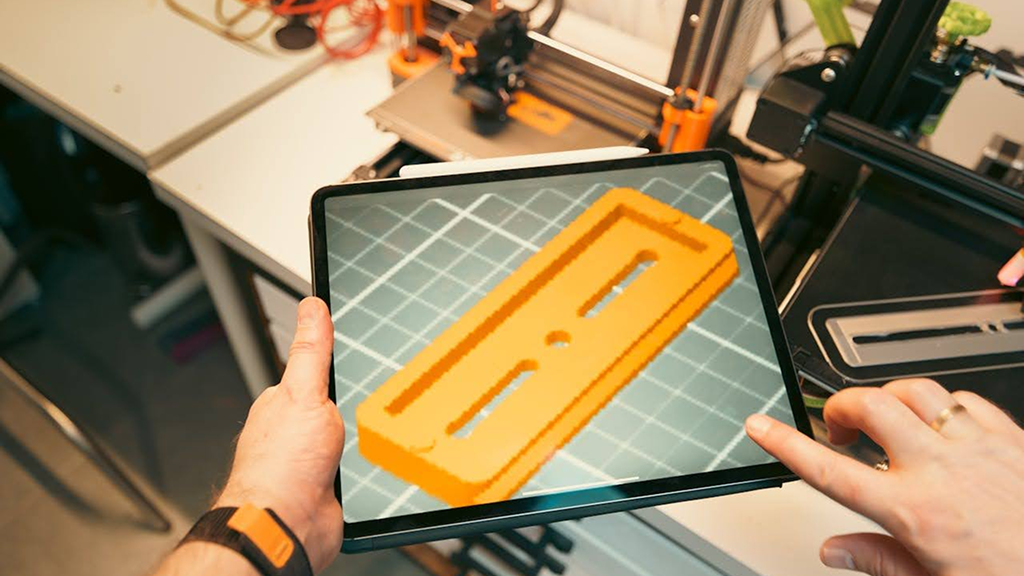

Software forms an integral part of the 3D printing ecosystem. Multiple software are required to complete the 3D printing process. These include CAD design softwares like Catia, Creo, Fusion 360, and Solidworks to create the 3D model.

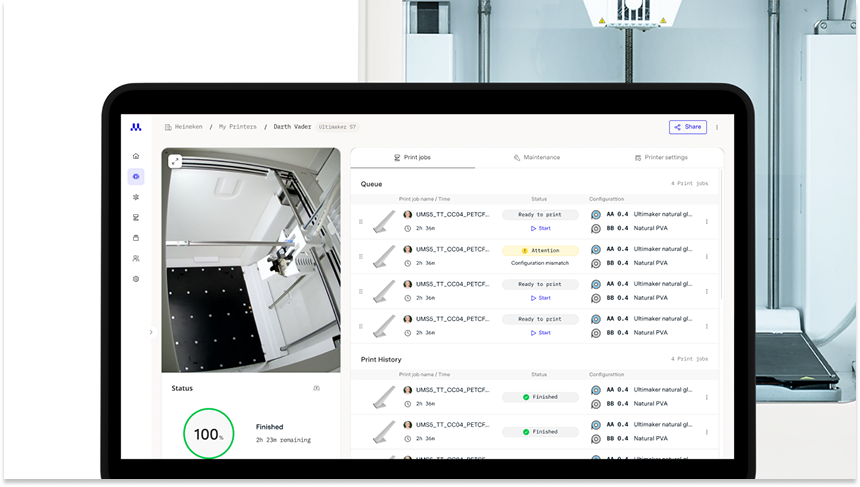

Slicing software takes the design file and prepares it for the printer. New cloud-based options such as Ultimaker Digital Factory add features like remote printing and monitoring, team collaboration and print queuing, and reporting for management.

Material

For additive manufacturing to make sense for your applications, material choice is crucial. Different AM technologies offer different ranges of materials. Some very specific and some more broad. The materials can be polymers, metals, composites, etc. (more on this in the Materials section of this article).

3D printer and supporting accessories

This is where the actual 3D printing process takes shape. Here, the design and associated settings combine to create the three-dimensional object. The final file is sliced and the print is started. In addition to the printer itself, other hardware accessories may come into play.

Post-processing

Almost every 3D printed object requires some level of post-processing and so this also forms an essential part of the 3D printing ecosystem. Post-processing techniques range from basic support removal, sanding, and painting to more complex processes like debinding and sintering for FDM metal prints which results in a solid metal part. Different technologies have different requirements as well. Powder-based systems require the removal of the print from a bed of powder, while resin-based systems require washing harmful resins and post-curing.

Materials used in additive manufacturing

The range of materials compatible with additive manufacturing technologies has expanded dramatically since the early days of rapid prototyping, enabling a wide array of industrial applications. This diversity of materials is a key factor in AM's growing adoption across various sectors. Let's explore the diverse materials used in AM:

Polymers

Polymers were the very first materials to be developed for 3D printing. FDM 3D Printers use filament on spools like those manufactured by Ultimaker. Ultimaker manufactures and sells high-quality polymers like ABS, Nylon, PET Carbon Fiber, PLA, ASA, PETG, PVA and more.

Polymers are also used as resins in Vat Photopolymerization type of 3D printers and as powders in powder-bed fusion type of 3D printers.

They remain the most widely used materials in additive manufacturing, offering versatility and cost-effectiveness.

Recent developments have introduced high-performance polymers with enhanced mechanical properties, temperature resistance, and chemical compatibility, expanding the use of AM in aerospace and automotive industries.

Metals

Metal AM has seen significant growth, particularly in industries requiring complex, high-value parts:

- Titanium alloys: Prized in aerospace and medical applications for their strength-to-weight ratio

- Aluminum alloys: Used for lightweight parts in automotive and aerospace

- Stainless steels: Offering corrosion resistance for various industrial applications

- Superalloys: Such as Inconel, used in high-temperature environments

- Precious metals: Including gold and silver for jewelry and dental applications

Advancements in metal AM have focused on improving material properties, reducing porosity, and developing new alloys specifically optimized for additive processes.

Ceramics

Ceramic is a popular material generally associated with pottery or kitchen items. But it is also widely used in industries because of its ultra-high heat tolerance. As a result, companies have developed ceramic materials for 3D printing in FDM, SLA, and Binder Jetting technologies.

While less common than polymers and metals, ceramic AM is gaining traction in specialized applications:

- Oxide ceramics: Such as alumina and zirconia, used in dental and medical implants

- Technical ceramics: Offering high temperature and wear resistance for industrial components

Ceramic AM processes are evolving to address challenges like shrinkage and porosity, opening up new possibilities in industries requiring high-performance ceramic parts.

Composites

Composite materials in AM combine the properties of different materials to achieve enhanced performance:

- Fiber-reinforced polymers: Incorporating carbon or glass fibers for increased strength and stiffness

- Metal matrix composites: Combining metals with ceramic reinforcements for improved wear resistance

- Functionally graded materials: Varying material composition throughout a part to optimize properties

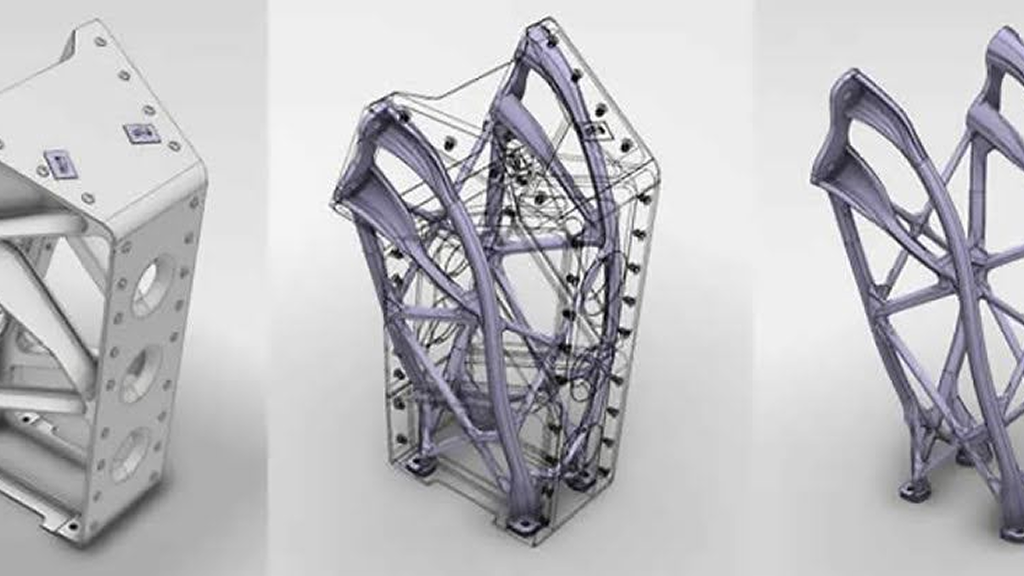

The ability to precisely control material placement in AM allows for the creation of composite structures not possible with traditional manufacturing methods.

Biomaterials

The medical and bioengineering fields are driving innovation in biocompatible and biodegradable materials for AM:

- Biocompatible polymers: Such as PCL and PLA, used in tissue engineering scaffolds

- Hydrogels: Soft, water-containing networks used in bioprinting applications

- Bioceramics: Including hydroxyapatite for bone tissue engineering

These materials are enabling the production of patient-specific implants, drug delivery systems, and even living tissue constructs.

Concrete

Concrete is one of the newest materials to be introduced in 3D printing to cater to the construction application. The use of this material is quite limited right now but shows huge potential in the coming future.

Novel and Emerging Materials

The field of AM materials is constantly evolving, with researchers exploring new possibilities:

- Metamaterials: Engineered structures with properties not found in nature

- Smart materials: Capable of changing properties in response to external stimuli

- Nanomaterials: Incorporating nanoparticles to enhance specific properties

These cutting-edge materials are pushing the boundaries of what's possible with additive manufacturing, opening up new applications and industries.

Material Development Challenges

Despite the wide range of materials available, several challenges remain in AM material development:

- Ensuring consistent material properties across different AM processes and machines

- Developing materials that can match or exceed the performance of traditionally manufactured parts

- Creating multi-material systems that can be processed simultaneously

- Improving the sustainability and recyclability of AM materials

Addressing these challenges is crucial for the continued growth and adoption of additive manufacturing across industries.