When using an FFF 3D printer, support material enables you to print models that would otherwise not be possible due to, well, gravity. It ‘supports’ the material above it so you can print objects with features like overhangs or cavities.

Which 3D printing supports to use: PLA, PVA or Breakaway

With the launch of Ultimaker’s Breakaway support material, there are now even more options for supporting your 3D prints. But which one is right for your design? Let’s take a look at the different options and when to use each one.

For more advanced users, support material can also give you more design freedom. With it you can orient your model exactly how you want for the best results, or create designs with moving parts built in that are free to move once you remove the support material.

Build material supports

The original way to support your 3D print. If you are printing with, for example, PLA, then 3D printing software like Ultimaker Cura can create support structures for your model that will print in the same material.

If you are using a single-extrusion 3D printer, this is the only way to print support structures. It’s also a good option if you don’t want to worry about material compatibility. Not all build materials are compatible with separate support materials.

The main drawback to using build material supports is that when you remove the supports manually, you will never be able to get a model that is 100% accurate compared with your original design. If you cut or sand your supports too much or leave any small bumps, your model will be a slightly different shape to your design.

This can be a problem if your 3D print needs to be very accurate, for example you are prototyping a part to test its fit or form.

Cutting and sanding away supports can also damage the surface of your 3D print and need post-processing techniques like polishing to achieve a good quality surface finish.

To remove build material supports, you will need a cutting implement (most people use a knife or pliers) and sandpaper to get rid of any final traces.

Dissolvable PVA

If your 3D printer can print more than one material, then it is also possible to combine your build material with a separate support material that is easier to remove.

PVA is a water-soluble support material. Because it dissolves away when submerged in water, it gives you almost complete design freedom. Large overhangs, cavities, intricate shapes are all possible, and there is no risk of scratching your print while removing the support. It leaves behind a very smooth surface.

One downside of PVA is that while it is effortless to remove, it does take several hours to dissolve so it can hold up your 3D printing workflow. PVA is also more expensive than other support material options and its quality can degrade if not stored properly.

Ultimaker PVA is optimized for use with PLA, Nylon, and CPE.

To remove PVA, all you need is a container of tap water big enough for your model. Read our complete guide to dissolving PVA.

Breakaway supports

The newest support material offered by Ultimaker, Breakaway has some similarities to the other types of support.

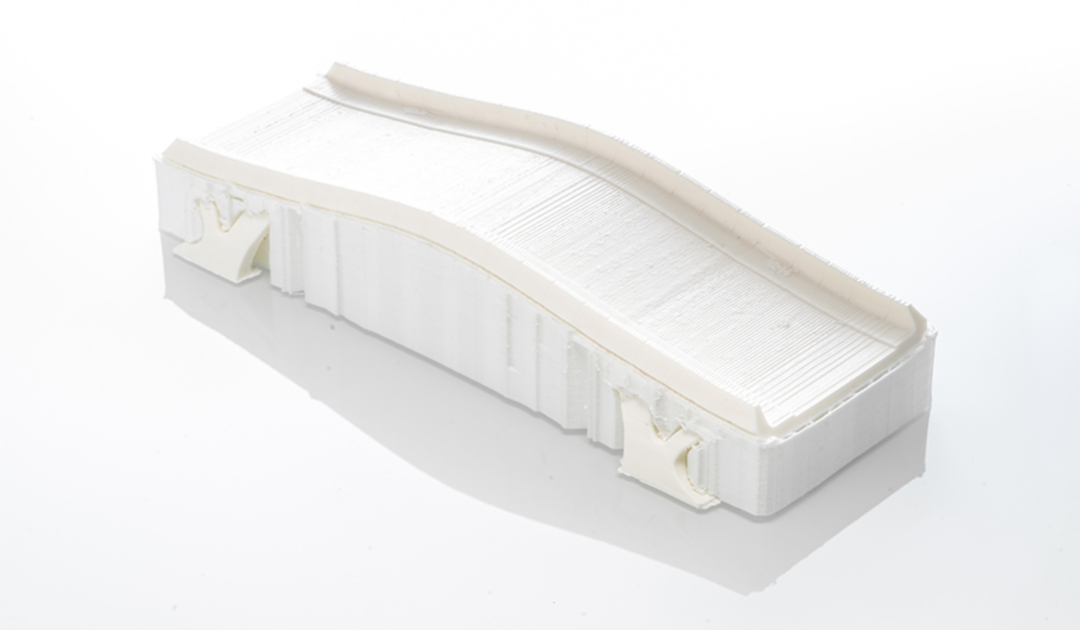

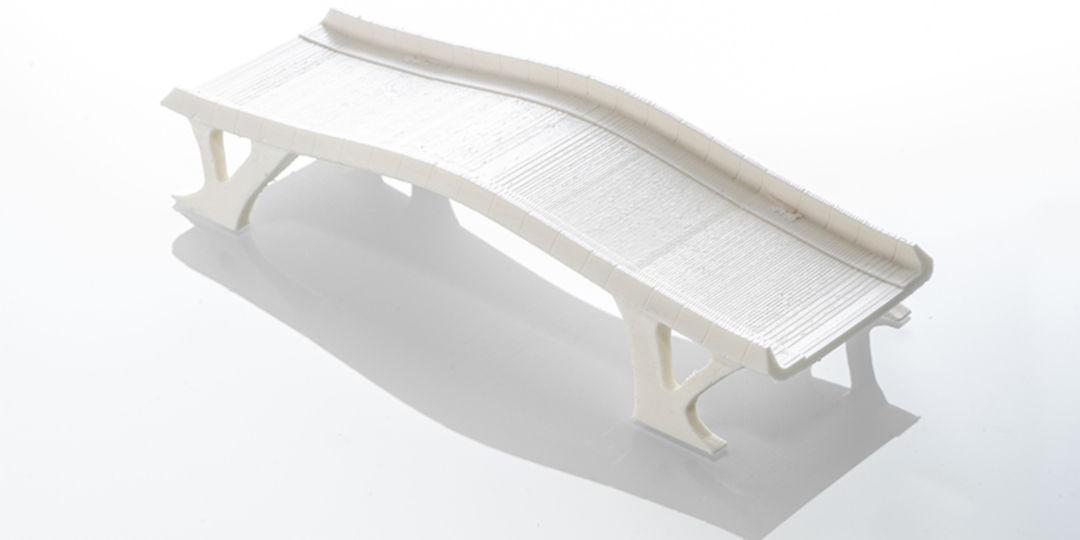

Like build material, it is removed manually. But like PVA, it is a separate material printed with dual extrusion.

The result is a balance between the advantages of the other support material options. You can remove Breakaway by hand so there’s no need to wait hours for anything to dissolve, but it also peels away cleanly from the rest of your print so you have an accurate model and don’t need to post-process it.

However, for the smoothest surface finish we still recommend PVA. And the Breakaway material in your print needs to be accessible for you to remove it, so you do not have complete design freedom.

Ultimaker Breakaway is optimized for use with ABS, Nylon, PLA, CPE, and CPE+.

To remove Breakaway supports, you will need a set of pliers. Read our complete guide to removing Breakaway.

Quick comparison: When to use...

Build material supports: When you don’t need a print that is 100% accurate compared to the dimensions of your 3D design. Or if you only have a single extrusion 3D printer

PVA: Ideal if you’re printing a complex shape or when you want a really smooth surface finish beneath your supports, but takes several hours to dissolve

Breakaway: If you’re short on time, Breakaway is quicker to remove than PVA and keeps the dimensional accuracy of your print, with a quality surface finish