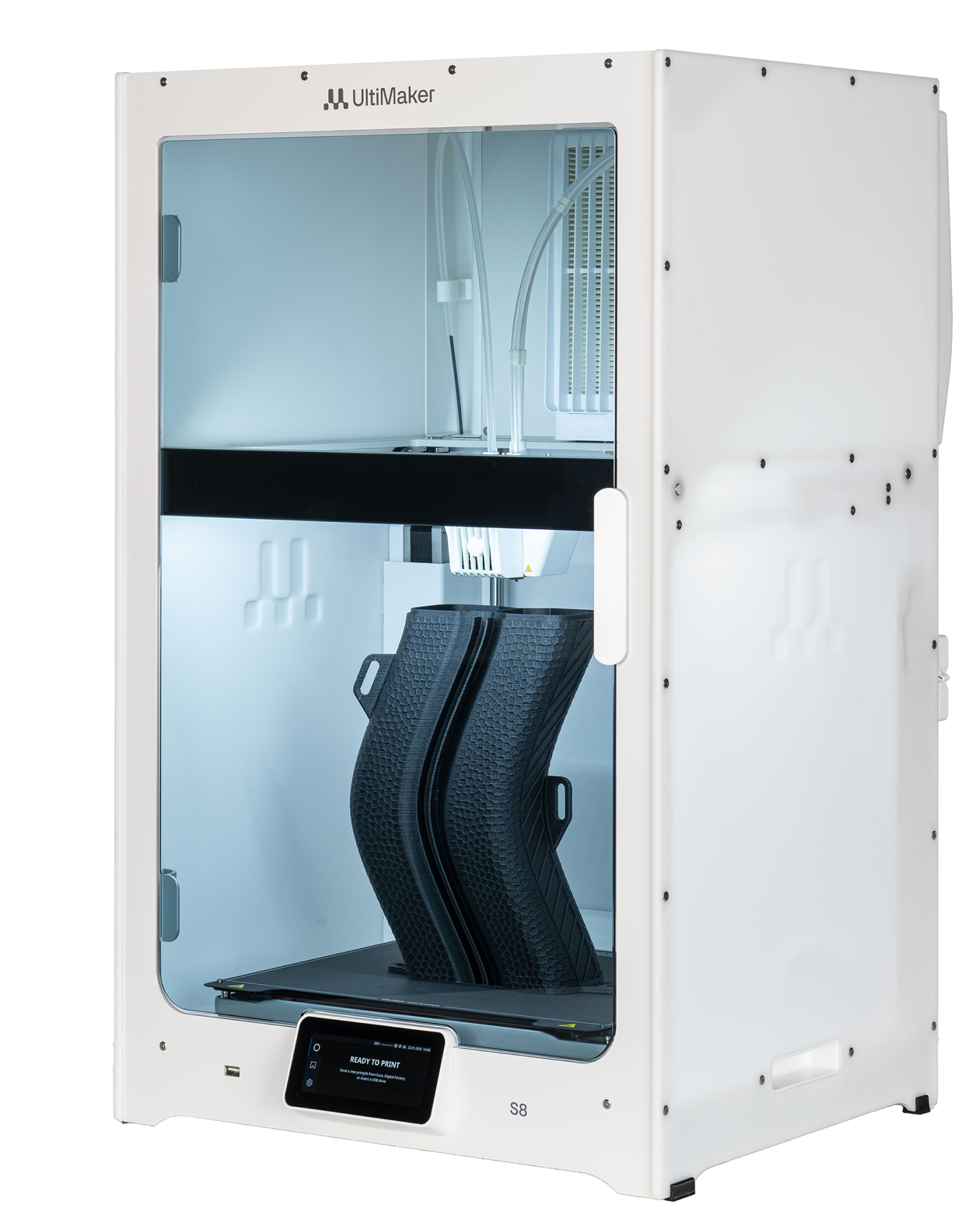

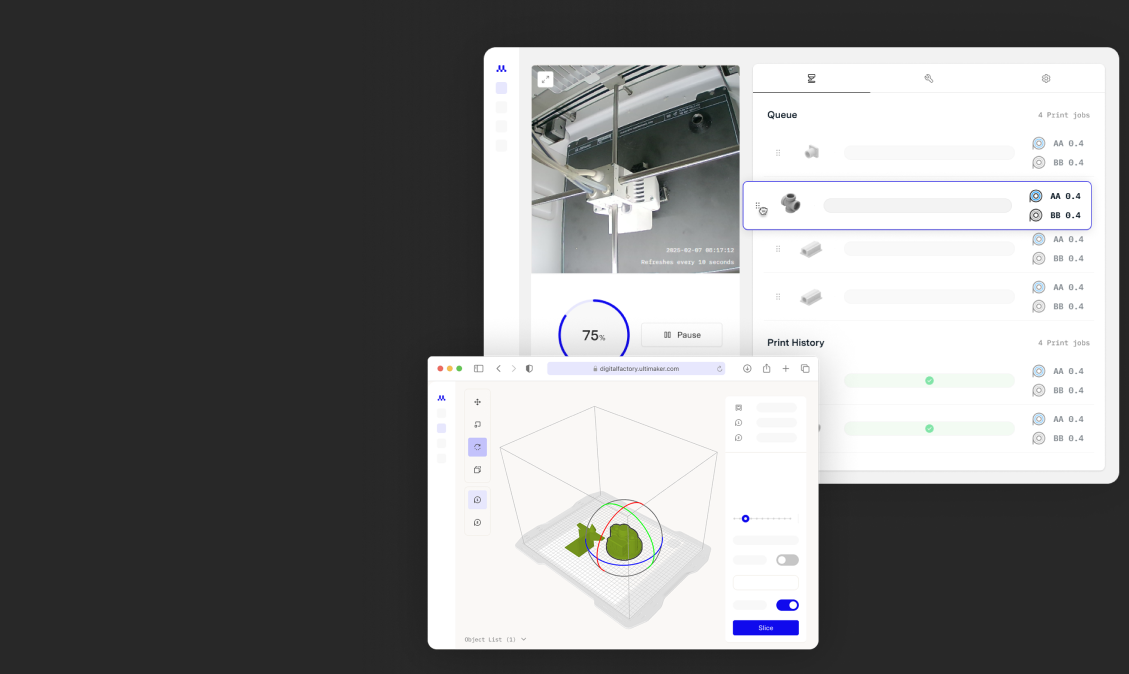

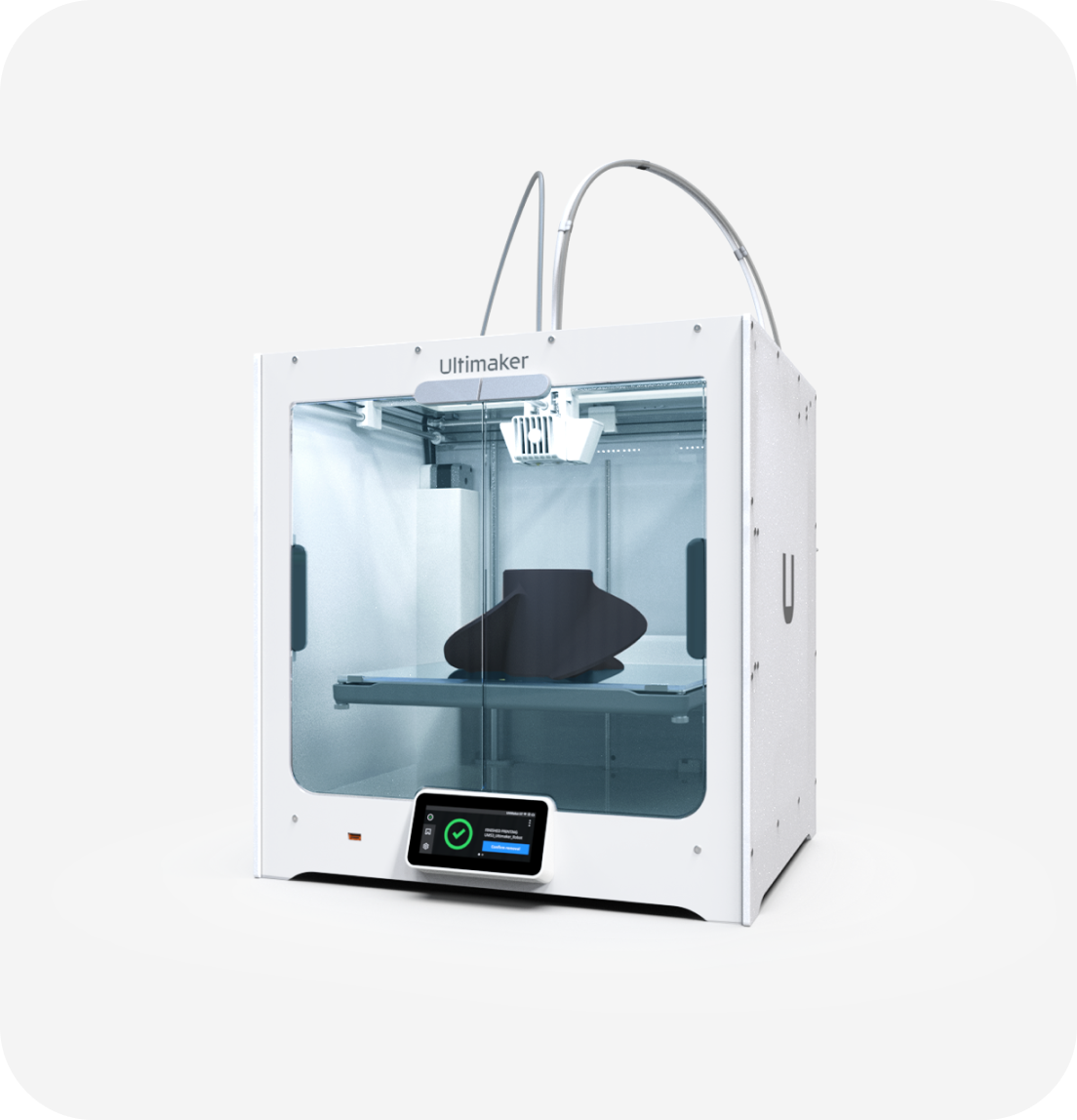

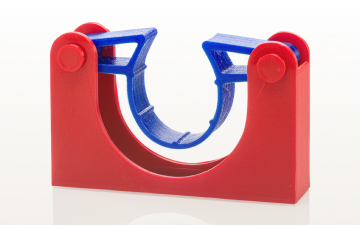

The UltiMaker Cheetah motion planner

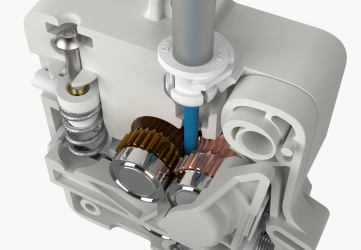

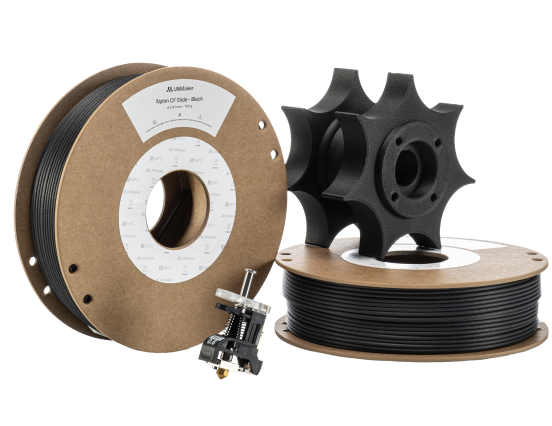

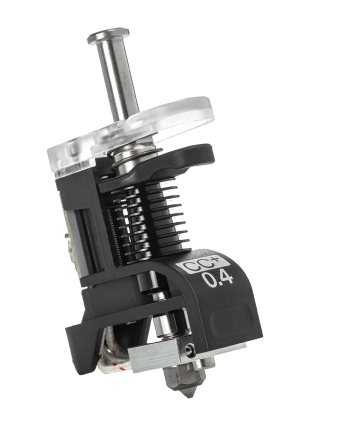

Unlock new levels of efficiency with the new UltiMaker Cheetah motion planner, redesigned high flow print cores, built in accelerometer, new feeder system and improved firmware

Up to

500 mm/s

speed

50 000 mm/s2

acceleration

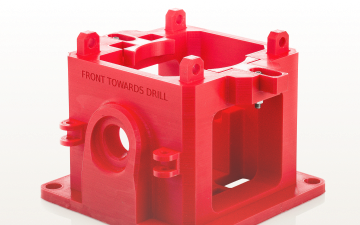

while also improving the quality of the print to 0.15mm ± 0.15%.