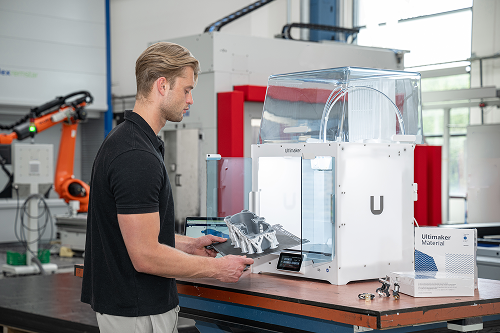

Fast, durable solution with in-house 3D printing

By switching to UltiMaker 3D printing with Nylon CF Slide, the manufacturer was able to produce lightweight yet strong transition combs directly in-house. The material’s wear resistance and low-friction properties made it ideal for continuous use in demanding conveyor environments.

Each comb could be tailored exactly to the conveyor’s needs - and when wear eventually sets in, new parts can be printed in just hours instead of waiting weeks.

Efficiency gains at a glance:

- Cost per part reduced from €30 to just €8.80

- Lead time cut from 2 weeks to only 3 hours

- Material chosen: UltiMaker Nylon CF Slide for strength and durability

Designed to last, built for speed

The printed geometry of the combs was optimized to guide products smoothly with minimal friction. Thanks to Nylon CF Slide, parts required fewer supports, were easy to post-process, and showed excellent layer adhesion - ensuring long service life even under constant use.

Small parts, big impact

Transition combs may not be the flashiest components on the line, but their role is critical. With 3D printing, they can be made faster, at lower cost, and in designs tailored for maximum efficiency.

For this manufacturer, the result was a smoother, more reliable conveyor system—and a powerful reminder that even the smallest parts can deliver big value when produced with additive manufacturing.

Discover how UltiMaker’s professional 3D printing solutions can help you cut lead times, reduce costs, and keep operations running smoothly - no matter your industry.

Curious to see how your organization can benefit from 3D printing? Book a call with one of our applications engineers.