UltiMaker S8

Unlock new levels of efficiency with the new UltiMaker Cheetah motion planner, redesigned high flor print cores, built in accelerometer, new feeder system and improved firmware

Learn more >

Unlimited application potential.

Specialized for engineering applications.

High-performance and certified materials

Over 300 materials to choose from.

From polymers to composites to metals.

Versatility and modularity, now supercharged with innovations like the UltiMaker Cheetah for up to 4x productivity. It's S5 familiarity, redefined for today's demands.

Up to 4x productivity and improved quality, powered by the new UltiMaker Cheetah motion planner.

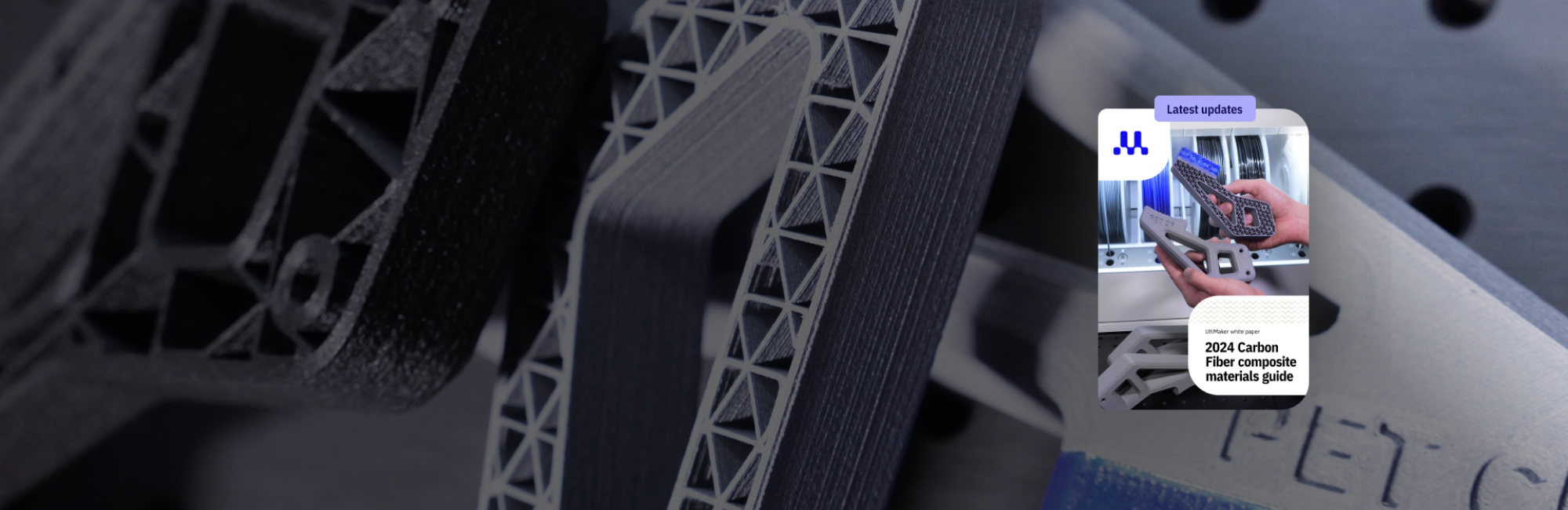

This guide has been created by UltiMaker’s 3D printing experts. It also features examples from real-life engineers, so you can learn from those already using 3D printing to reduce production time and costs.

Unlock the full potential of carbon composites with UltiMaker’s updated Carbon Composites Guide.

Unlock new levels of efficiency with the new UltiMaker Cheetah motion planner, redesigned high flor print cores, built in accelerometer, new feeder system and improved firmware

El UltiMaker Factor 4, nuestro más reciente modelo de impresora 3D de nivel industrial, optimiza la producción, simplifica los procesos y garantiza la continuidad operativa.

Diseño. Impresión. Repetición. Desbloquee aplicaciones de alto valor y reduzca costos con nuestro ecosistema profesional de impresión 3D.

La potencia de la S Series radica en su versatilidad. Explore nuevas aplicaciones de impresión 3D utilizando la más amplia selección de materiales en el mercado, lo que las hace perfectas para la creación de prototipos y ayudas de fabricación de todos los tamaños. Utilizan filamento de 2.85 mm y desbloquean todo el poder de UltiMaker Cura para simplificar su flujo de trabajo.

Learn more

La más amplia selección de filamentos para impresoras 3D de alta calidad en el mercado. Formulados para las impresoras 3D de la serie S y la serie Method para lograr resultados en casi cualquier aplicación que pueda imaginar.

S series materials

Confiado por millones de usuarios, UltiMaker Cura es el software de impresión 3D más popular del mundo. Prepare impresiones con unos pocos clics, intégrelo con software CAD para un flujo de trabajo más fácil, o sumérjase en configuraciones personalizadas para un control profundo.

Descargue gratuitamente