Future trends and innovations in 3D printing for manufacturing

Advanced materials

Researchers are developing new high-performance materials specifically designed for 3D printing. These include advanced metal alloys, ceramics, and composite materials that offer improved strength, heat resistance, and functionality. For example, the development of printable superalloys could further expand aerospace applications, while biocompatible materials are advancing medical implant possibilities.

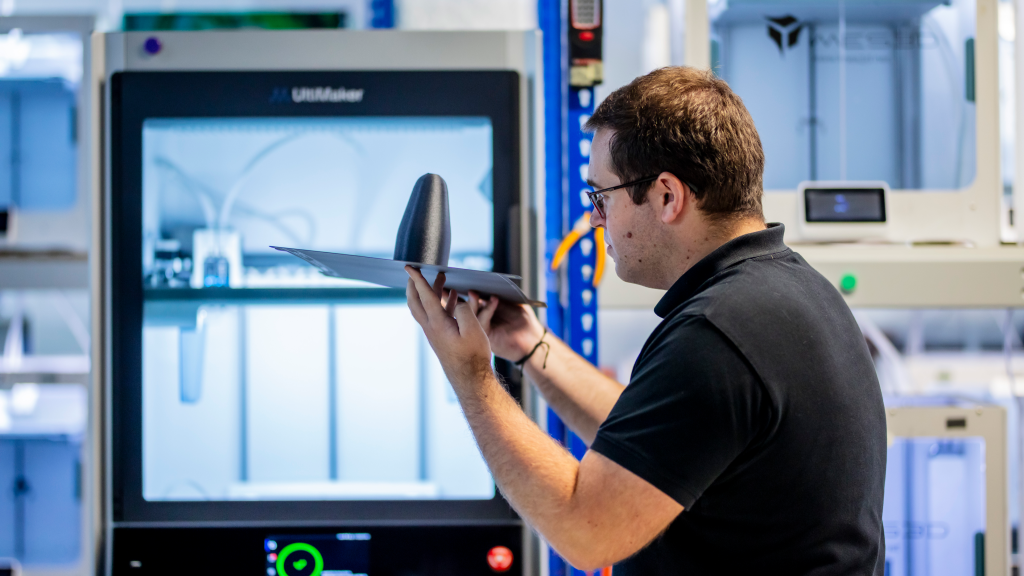

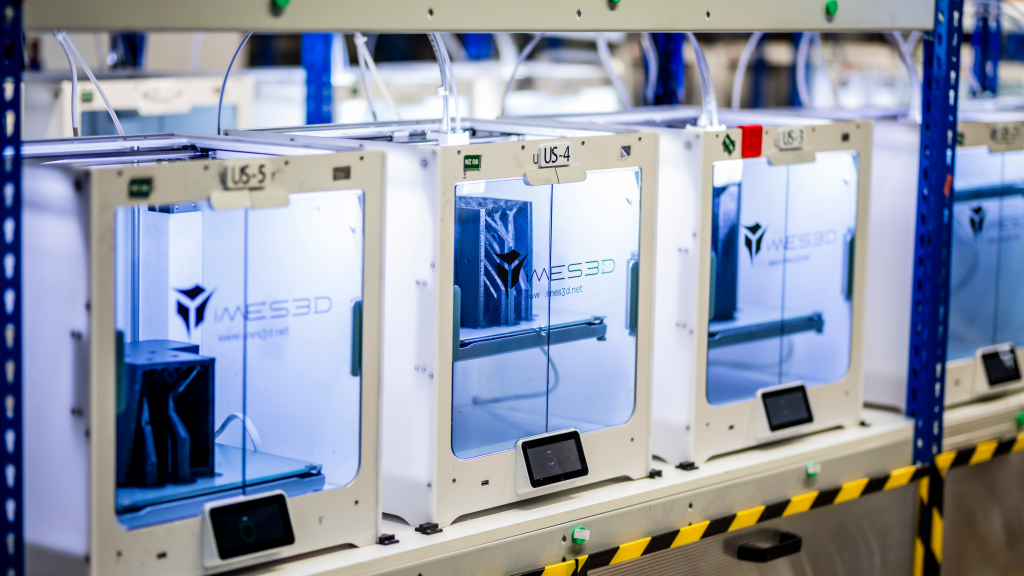

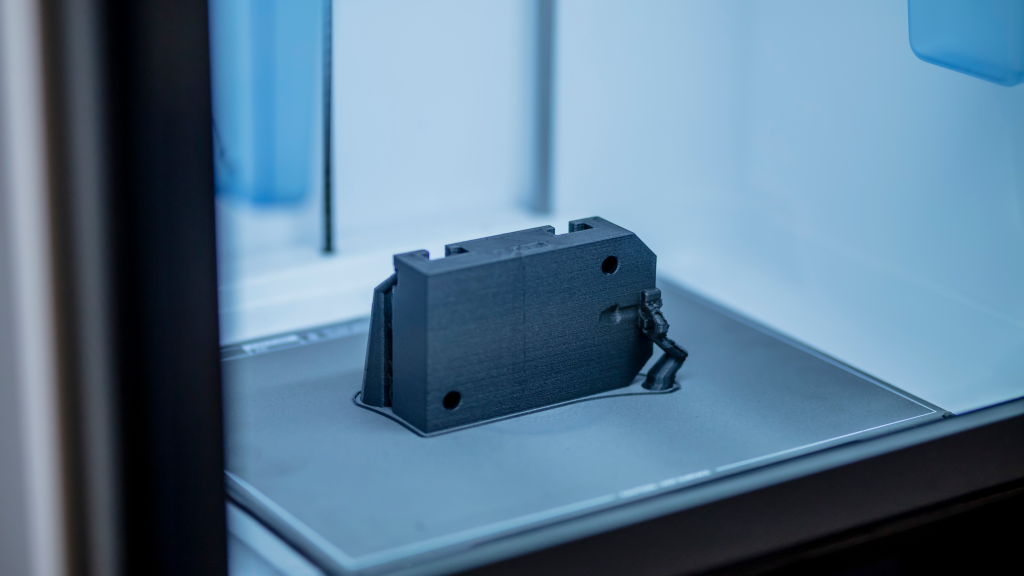

Ultimaker: Materials Enabling Versatility in Manufacturing

UltiMaker’s ecosystem of advanced printing solutions provides manufacturers with the flexibility to choose from a wide range of materials tailored to specific applications. From durable industrial plastics to flexible polymers, these materials enable the production of functional parts that can withstand the rigors of industrial environments even replacing traditional materials such as aluminum or steel in certain applications without compromising on part reliability or function.

As a reference starting point here are 3 of the materials used in the above examples:

UltiMaker Tough PLA:

- Applications: Strong and impact-resistant parts such as jigs, fixtures, and prototypes.

- Use case: Heineken uses Tough PLA to print durable production line components, including bottle guides and tool organizers, ensuring longevity while maintaining cost-effectiveness

UltiMaker Nylon CF

- Applications: High-strength, abrasion-resistant parts like gears, bushings, and conveyor belts.

- Use case: Trivium Packaging leverages carbon reinforced nylon for parts like conveyor infeed worms, which must endure high wear and tear in a manufacturing environment

UltiMaker ABS

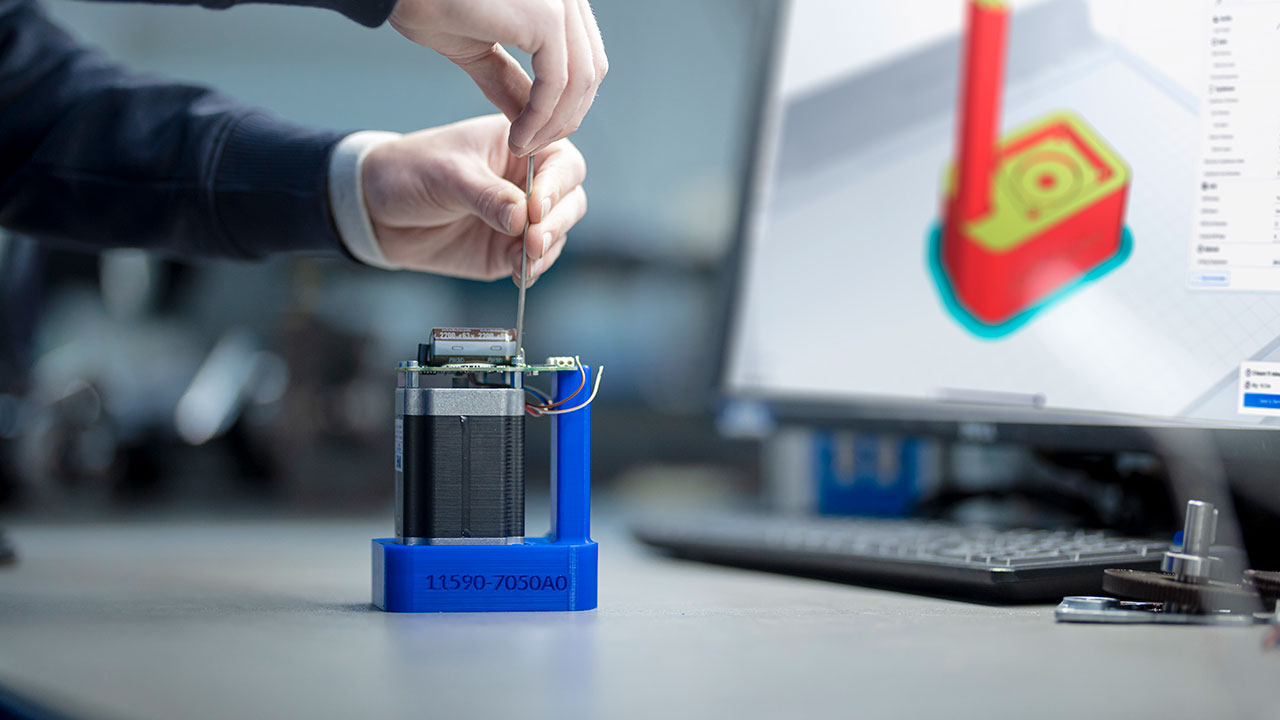

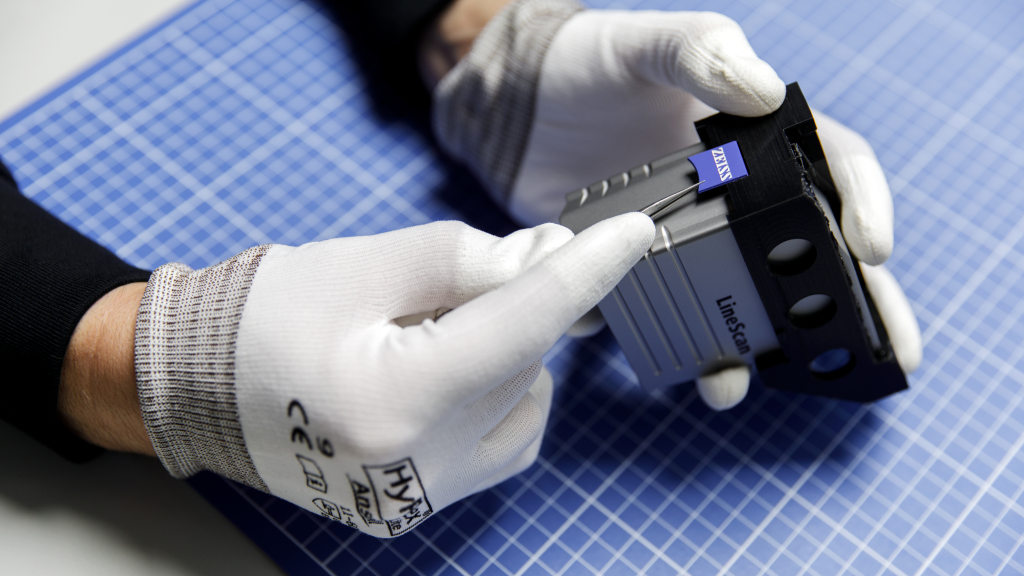

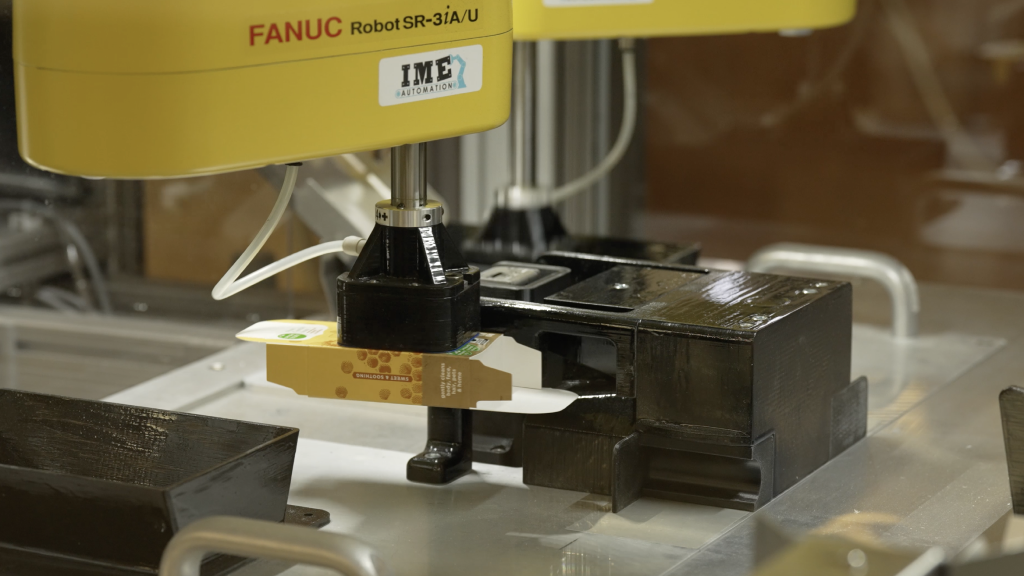

- Applications: Durable parts requiring smooth surface finishes, such as molds and protective covers.

- Use case: Zeiss’s adapter plates and label placement gauges are both made from ABS.

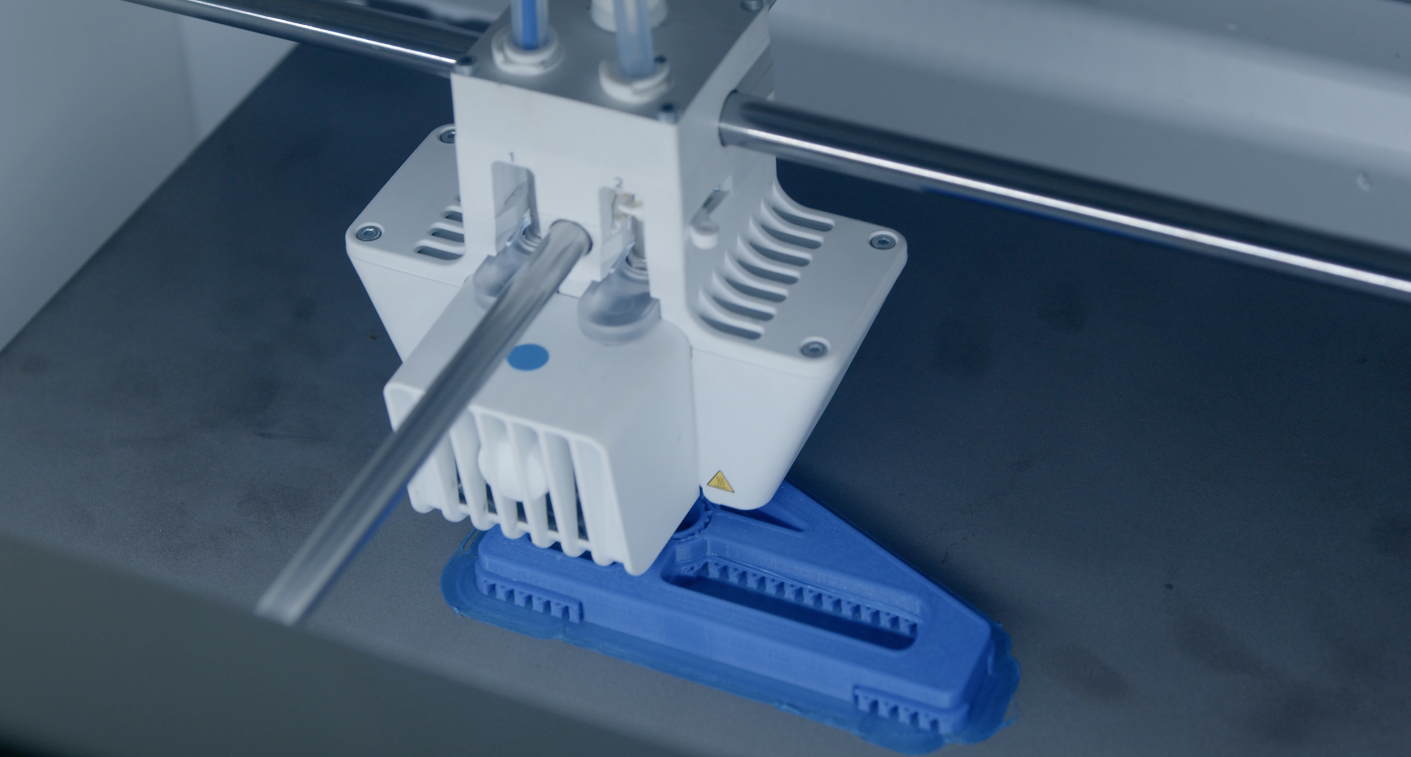

We recognize that material selection is one of the cornerstones of successful 3D printing applications in manufacturing and with a selection of over 200+ materials on the Marketplace, we’ve recently expanded the possibilities available on a single print with our dual-extrusion Factor 4 printer:

- Support Materials: Soluble supports like PVA allow for complex geometries with overhangs or internal structures that would otherwise be impossible to produce through traditional methods.

- Composite Structures: Pairing flexible materials like TPU with rigid materials like nylon creates parts with hybrid properties, such as flexible joints or shock-absorbing elements.

Artificial Intelligence and Machine Learning integration

To address consistency and quality control challenges, AI and machine learning algorithms are being integrated into 3D printing processes. These technologies can optimize print parameters in real-time, predict and correct for potential defects, and even generate optimized designs based on specified performance criteria. This integration promises to improve part quality, reduce waste, and accelerate the design process.

High-speed continuous printing

Innovations in printer design are tackling the speed limitations of current technologies. Continuous liquid interface production (CLIP) and other emerging techniques promise to dramatically increase print speeds, potentially making 3D printing competitive with traditional methods for higher volume production runs.

Large-scale additive manufacturing

Advancements in large-scale 3D printing are expanding the size limitations of printed objects. From architectural-scale structures to large industrial components, these technologies are opening new possibilities for on-site, on-demand manufacturing of large parts.

Hybrid manufacturing systems

Combining additive and subtractive manufacturing processes in a single machine, hybrid systems aim to leverage the strengths of both approaches. These systems can 3D print near-net-shape parts and then machine them to final tolerances, addressing some of the post-processing challenges while maintaining the design freedom of additive manufacturing.

4D printing

An evolution of 3D printing, 4D printing incorporates materials that can change shape or properties over time in response to external stimuli like heat, moisture, or light. This technology could enable self-assembling structures, adaptive components, and new possibilities in fields like biomedical engineering and responsive architecture.

Sustainable practices

Future developments are focusing on further reducing the environmental impact of 3D printing. This includes the development of biodegradable materials, improved recycling processes for print waste, and more energy-efficient printing technologies.

Standardization and certification

To address regulatory challenges, industry stakeholders are working towards standardized processes and testing methodologies for 3D printed parts. These efforts aim to streamline certification processes and increase confidence in the reliability and consistency of additively manufactured components.

Conclusion

As these innovations continue to develop, 3D printing is poised to play an increasingly central role in manufacturing across industries. The technology's ability to enable complex designs, customize products, and produce parts on-demand aligns well with broader trends towards more agile, sustainable, and localized production. While challenges remain, the ongoing advancements in materials, processes, and supporting technologies suggest a future where additive manufacturing becomes an integral part of the industrial landscape, complementing and in some cases replacing traditional manufacturing methods.

The journey of 3D printing from a rapid prototyping tool to a versatile manufacturing technology has been remarkable, and its future evolution promises to be equally transformative. As industries continue to explore and push the boundaries of what's possible with additive manufacturing, we can expect to see new applications, business models, and innovations that will reshape the way we design, produce, and consume goods in the years to come.

To gain a deeper understanding of how 3D printing is benefiting various manufacturing processes, we recommend reading our comprehensive guide on the benefits of 3D printing in manufacturing. This resource provides valuable insights into how businesses can leverage additive manufacturing to enhance their production capabilities and stay competitive in today's rapidly evolving industrial landscape.