Researchers at Cardiff University use 3D printing to create small devices that move small volumes of fluid and are used in various areas of research. 3D printing makes it possible to share the devices with other researchers, making the study of microfluidics more accessible to a wider audience. The 3D printed devices offer a cost-effective alternative to the traditional ones, which are expensive and require specialized skills and equipment. As technology advances and more materials become available, the application of 3D printing in microfluidics research continues to grow.

Microfluidics research

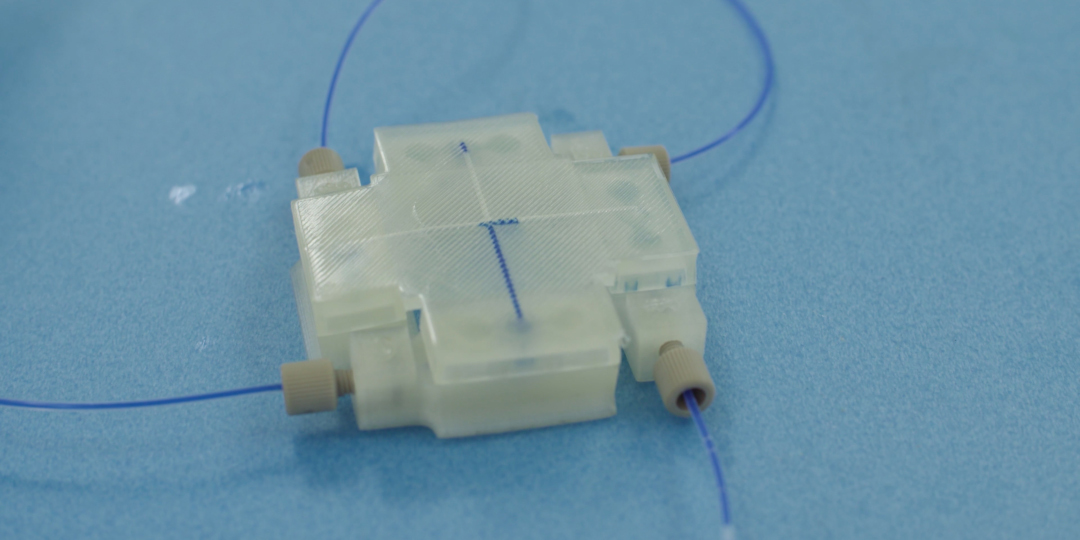

Microfluidic devices are small-scale circuits that are used to study the behavior of fluids in small volumes. The devices consist of small tubes that deliver small volumes of fluid to different sensors and other actuators in the circuit. Conceptually, they can be compared to plumbing systems that are reduced in size, onto a chip. The techniques used to create these microfluidic devices largely coincide with techniques used in the microelectronics industry to make the electronic chips in our computers and phones.

Microfluidic devices are used to make, for example, artificial cells for pharmaceuticals development, nuclear fusion targets for fusion energy production, and alginate capsules with neuronal stem cells inside to transplant into people with damaged spinal cords.

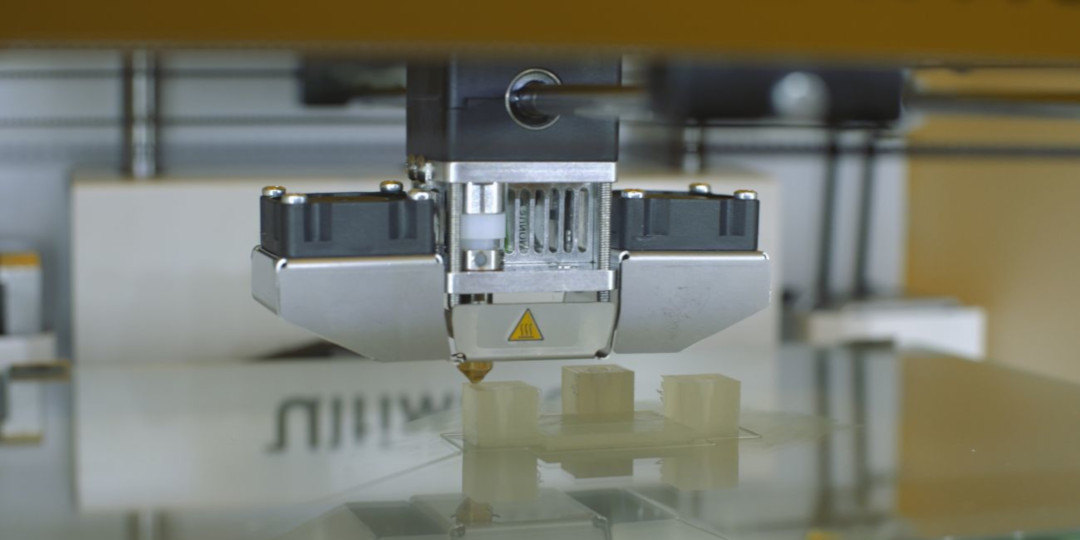

Traditionally, making these microfluidic devices was an expensive, lengthy and sophisticated process, requiring different types of expertise and using specialized equipment. The adoption of 3D printing significantly sped up this process, made it a lot cheaper, and allowed for the devices to be made on the spot in the research lab.

Microfluidics research studies the behavior of small volumes of fluid

3D printing microfluidic devices

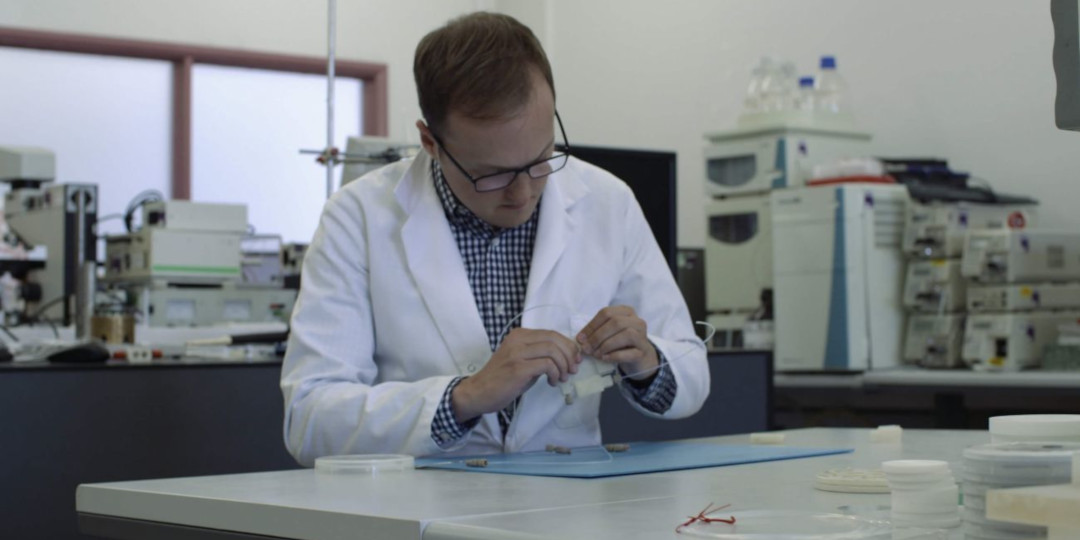

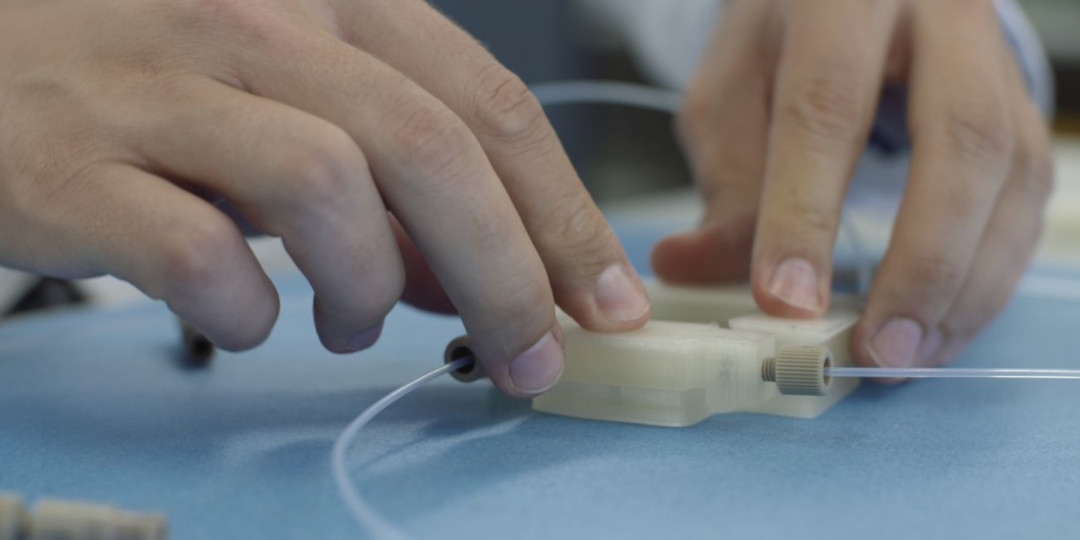

Using their Ultimakers, researchers at Cardiff University now 3D print the microfluidic devices they use in their studies. The 3D printed devices are based on a modular system that consists of standard building blocks that are assembled together. Starting off with a number of standard components (tubings, junctions, etc.), the research team developed different types of microfluidic systems and used those designs to make a modular system that any other researcher can use to make their own microfluidic devices.

3D printing gives rise to significant cost savings over the traditional methods and allows for rapid iterations on the design of the microfluidic devices. Since the designs can easily be shared with researchers in different locations, microfluidics research becomes accessible to other researchers as well. As David Barrow, Research Professor at Cardiff University, explains:

The simple purchase of a 3D printer means that as long as one is able to draw out an object in a suitable file format, using a wide range of available software tools, it is a relatively easy thing to print the object, and indeed make many revisions, relatively rapidly.

A microfluidic device is printed on the research lab's Ultimaker

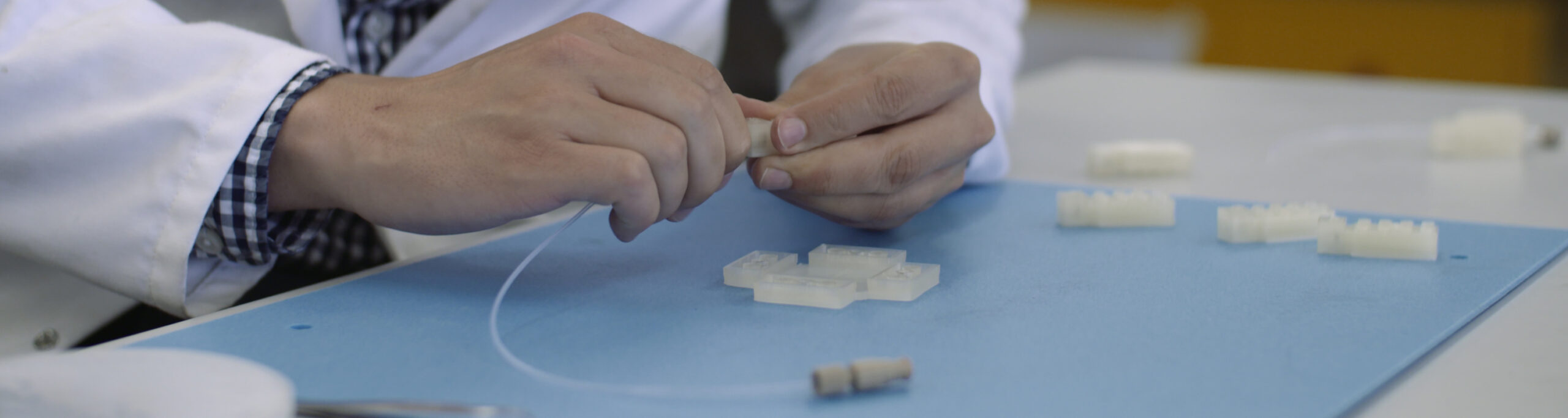

After printing, the different parts of the microfluidic device are assembled

Alex Morgan, Research Associate at Cardiff University, points out that other researchers previously discounted the use of 3D printing to create microfluidic devices as they were non-transparent and often leaked. By optimizing the print settings, however, Alex found that by printing in 50-micron layers and at a print speed of 30mm a second, devices can be printed that are both transparent and water-tight. The research group's recent publication explains how to do this.

3D printing in research

3D printing makes it possible to share the designs of microfluidic devices with other researchers so that they can print them out in their own lab, perform their tests and report back the results. In this way, microfluidics becomes accessible for other researchers that otherwise may not be using it.

As the 3D printing industry evolves, applications of 3D printing in research continue to grow. As Oliver Castell, Group leader for Membrane Biophysics and Engineering explains, as the diversity of available materials increases and the precision of the machines improves, it becomes possible to incorporate not only microfluidics but also optical and electronic components in one device. This will yield multi-functional devices made from different materials.

The role of 3D printing in research is expanding with these technological advancements. Take a look at our explore pages for more applications of 3D printing in research.