3D printing with Ultimaker in 2019: A year in review

It’s official – 2020 is here. We’re excited for the coming year and all that’s in store for both the Ultimaker community and the 3D printing industry. We’re also extremely proud of 2019 and all that was accomplished. Moving to a brand-new headquarters in Utrecht, for instance, or ALL3DP naming the Ultimaker S5 as 2019’s “Best Dual Extruder 3D Printer”. Needless to say, we’re proud, honored, and motivated to continue innovating with products that support the industry and our customers. Here’s a look back at some of the year’s high points on all fronts – hardware, software, materials, and people.

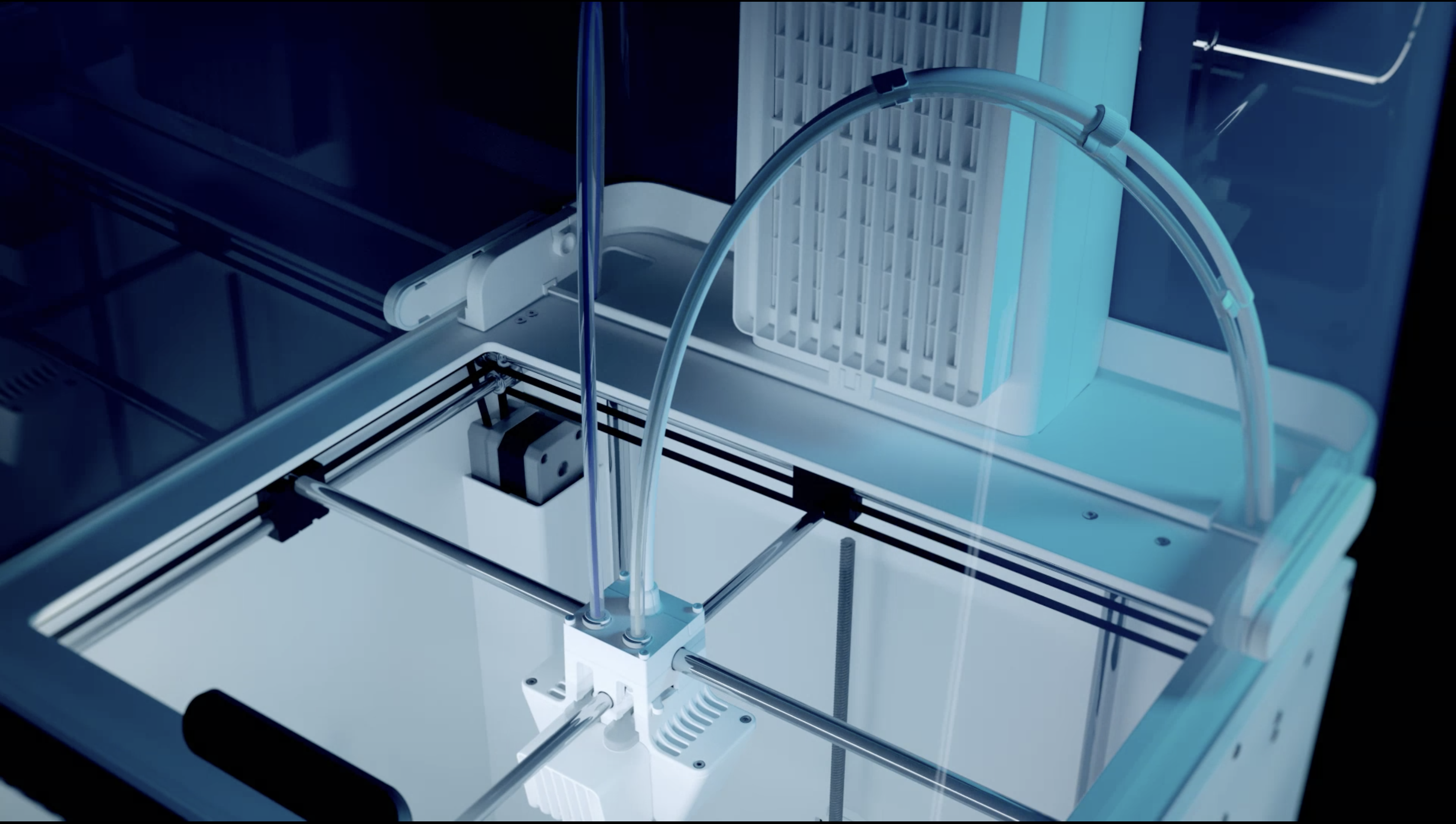

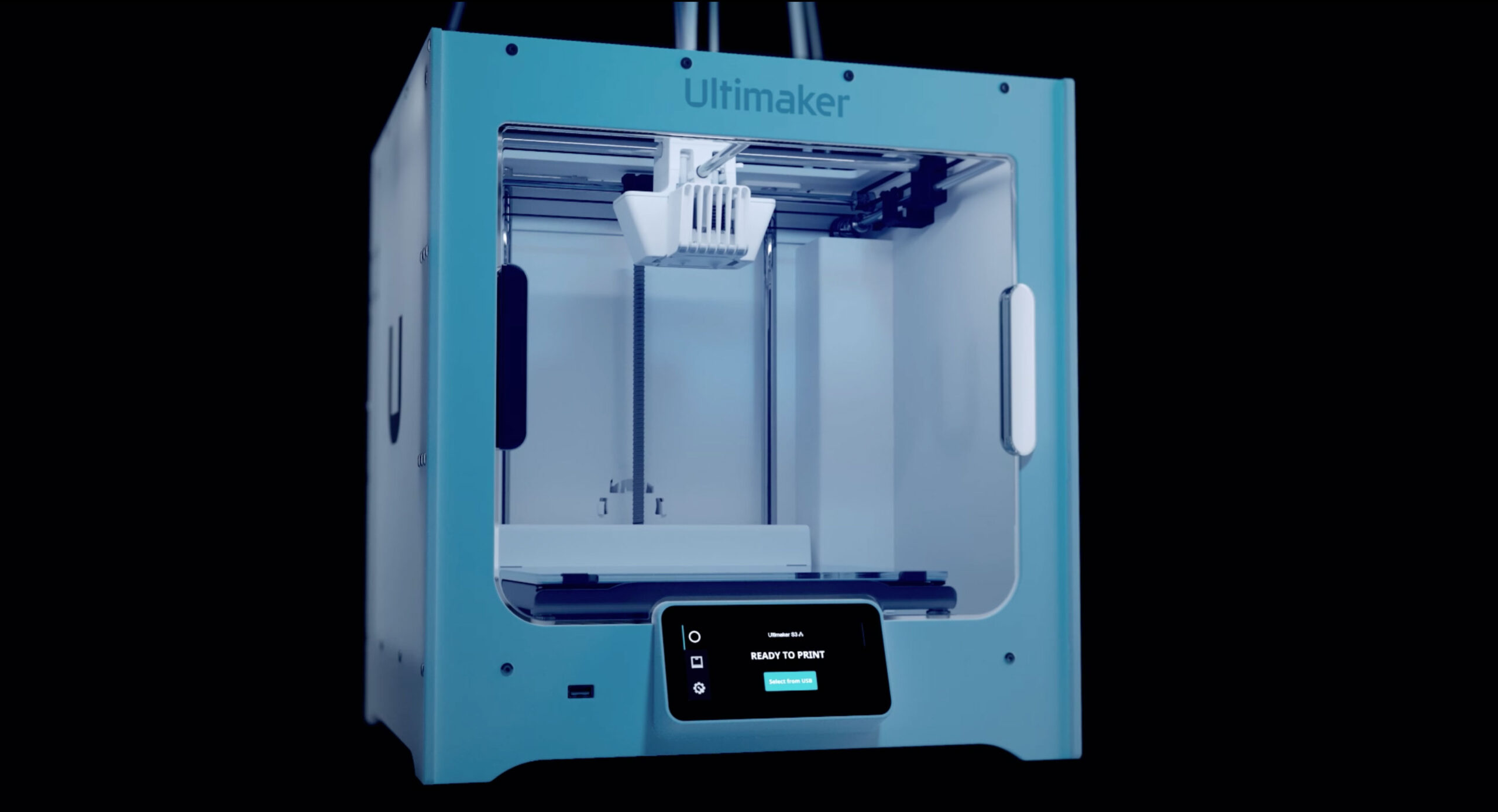

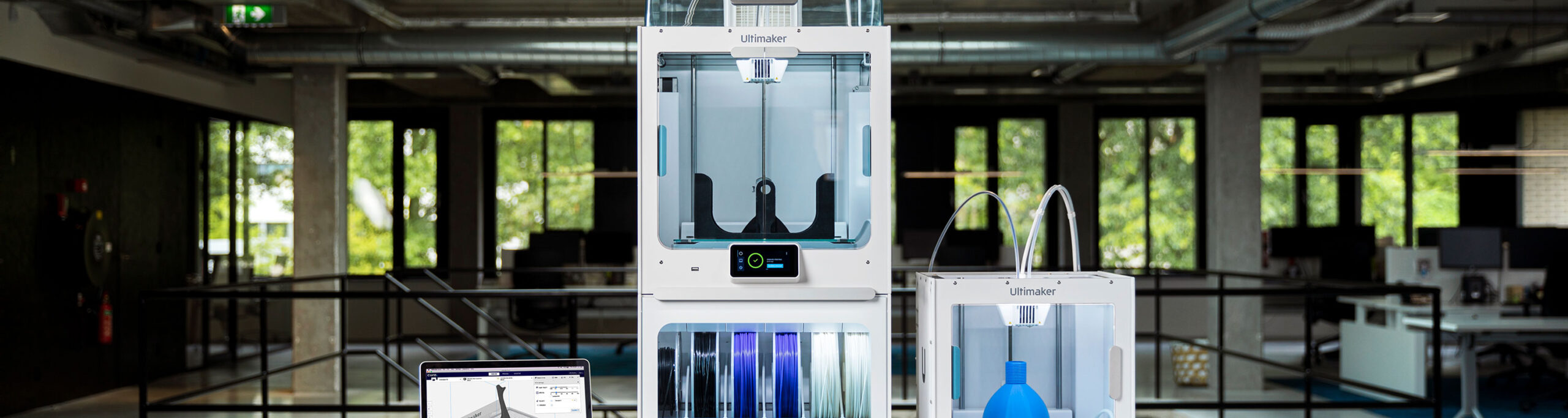

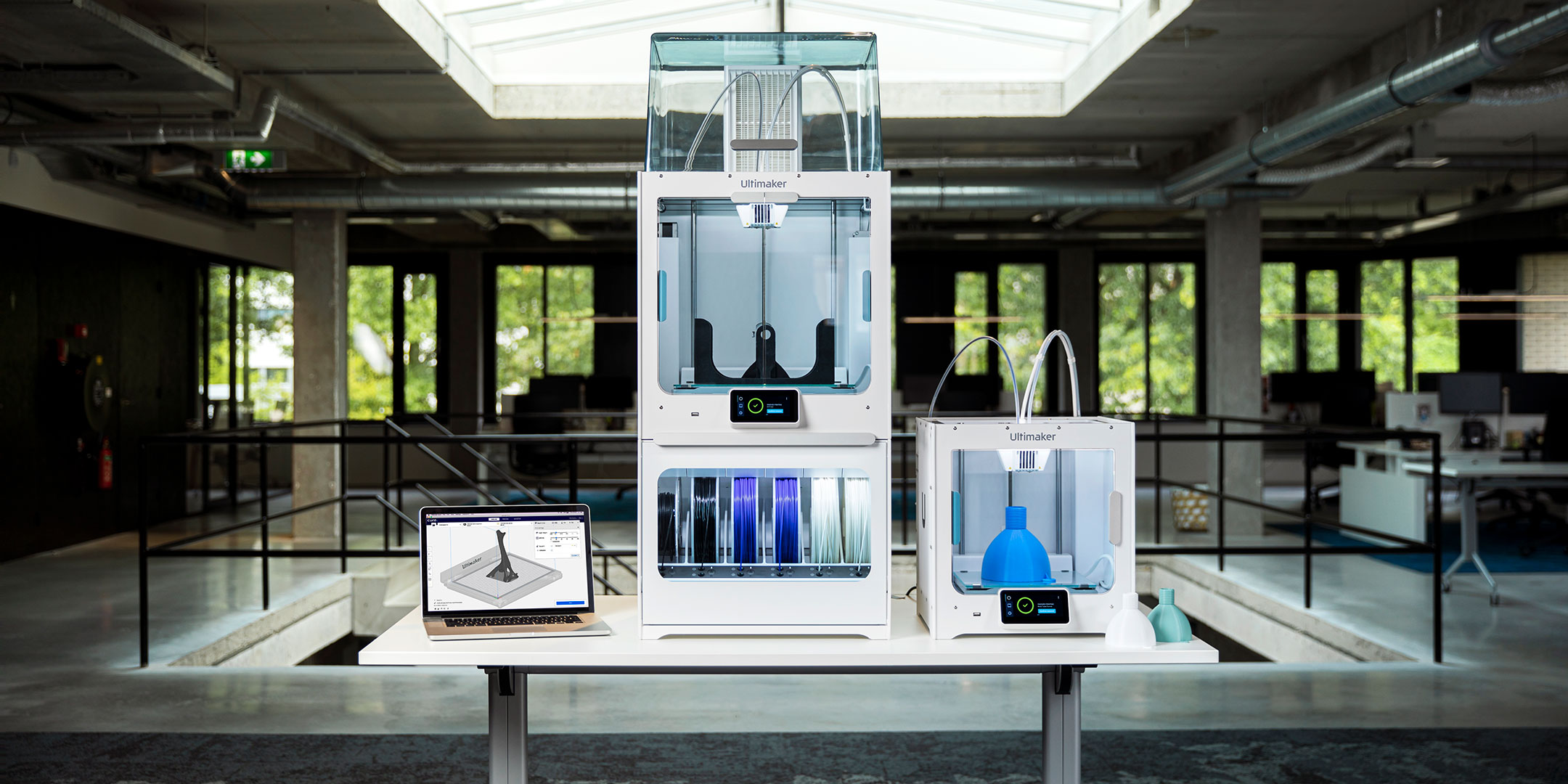

The launch of the Ultimaker S5 Pro Bundle the Ultimaker S3 were the hardware highlights of 2019. The Pro Bundle features the award-winning, composite-ready Ultimaker S5 3D printer, the Material Station – a six-spool prefeeder with humidity control and automatic material switching – as well as the Air Manager, a top enclosure with a material-matching EPA filter. Together, they integrate seamlessly, enabling always-on production that deliver real business value.

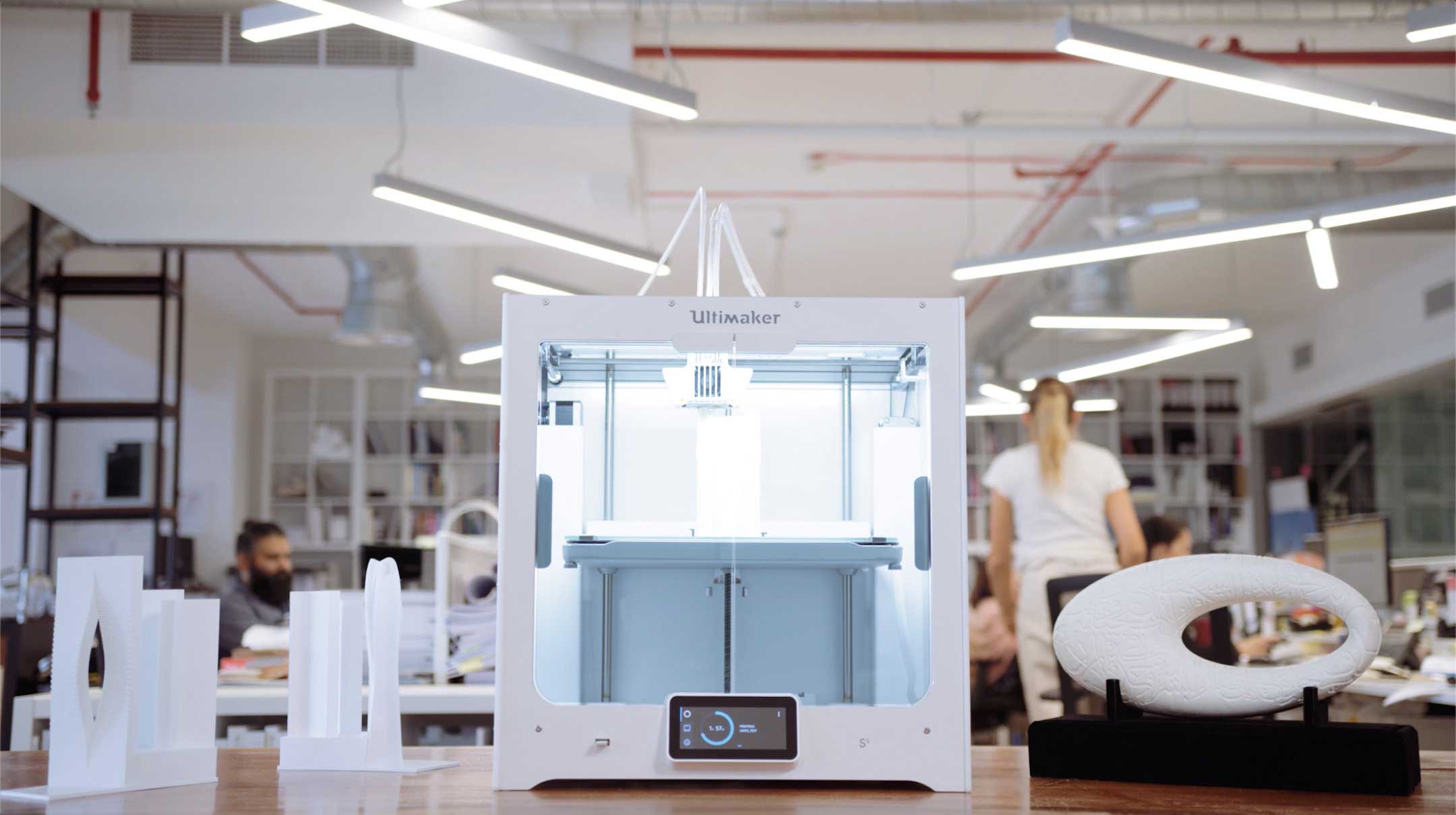

The Ultimaker S3, meanwhile, delivers many of the best features of the Ultimaker S5, combined into a smaller, more affordable device. With composite-ready dual extrusion and a footprint suitable for any desk, the Ultimaker S3 enables professional performance for any budget.

Software: Intent profiles and application enablement

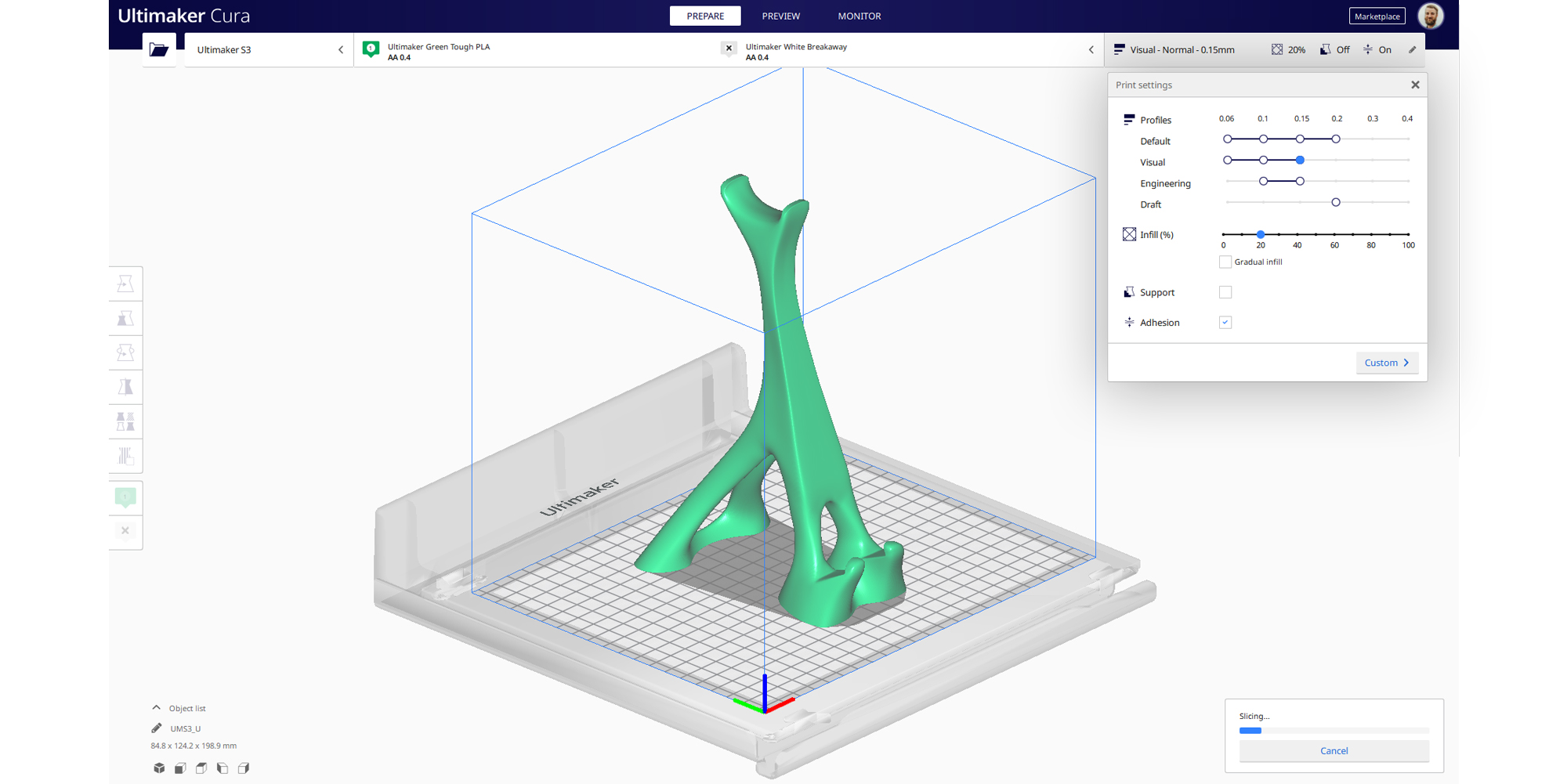

Print slicing with our open-source software, Ultimaker Cura, grew 124% in 2019, while G-codes for Ultimaker machines grew 40%. The total number of users per month nearly doubled. As well, the release of Ultimaker Cura 4.4 introduced three intent profiles, each with a specific professional application in mind: Engineering, Visual, and Draft.

The first quarter of the year saw the Ultimaker Cloud, a future-ready platform that allows for easy backup of Ultimaker Cura settings, access to the Marketplace, and remote printing. Ultimaker Cloud designed to meet the needs of today’s engineering and design professionals, simplifying the 3D printing workflow and providing seamless integration with a wide variety of industry-standard software applications and materials.

In October, the Ultimaker Marketplace hit 1 million downloads, cementing the idea that Ultimaker’s ecosystem – its hardware, software, and hardware – is truly unique, accelerating and streamlining digital manufacturing workflows around the world.

Materials: The Alliance powers up

The Ultimaker Material Alliance grew even stronger, as the Ultimaker Marketplace received its 100th material by mid-November. In Düsseldorf, Germany, the K trade show also served as a showcase for materials developed for additive manufacturing on Ultimaker 3D printers. K 2019 welcomed approximately 225,000 visitors from 165 countries, and more than 3,300 exhibitors from 63 countries.

Additionally, key players from the Material Alliance were in the spotlight at Formnext, the annual additive manufacturing exhibition in Frankfurt, Germany. There, the efforts of a collaborative push for the improvement and enablement of industrial applications of 3D printing were on fully display, including ESD-safe, recycled PLA, glass or carbon fiber-reinforced, and metal polymer composite materials.

Ultimaker also formed a partnership with LEHVOSS Group, in which the two companies will work together to obtain TÜV SÜD certification for LUVOCOM® 3F filaments on Ultimaker printers. The certification covers material properties and the print process provided by the Ultimaker S5 Pro Bundle, and is a major step towards industrialization and scalability of the 3D printing industry.

People and the industry: Uncharted territory and soaring successes

In November, we introduced the 3D Printing Sentiment Index, a measure of market awareness and adoption as well as overall sentiment towards the potential impact of the technology.

It is based on 2,548 interviews with qualified professionals and in-depth analysis of macro-economic factors. Five key elements were investigated: market awareness, adoption and install base, 3D printing growth indicators, perceived future impact and optimism, and technology infrastructure and ease of adoption.

In addition to the industry, we are also are well aware of the power of the people – rather, those individuals, businesses, and organizations which use Ultimaker 3D printers, and which are breaking new ground, pushing boundaries, and pioneering a new way of working.

Gerhard Schubert GmbH, for example, revealed its innovative ‘digital warehouse’ for on-demand manufacturing, providing its customers with future-proof, high-performance packaging machine solutions that are reliable, easy to operate, and flexible in terms of format conversion.

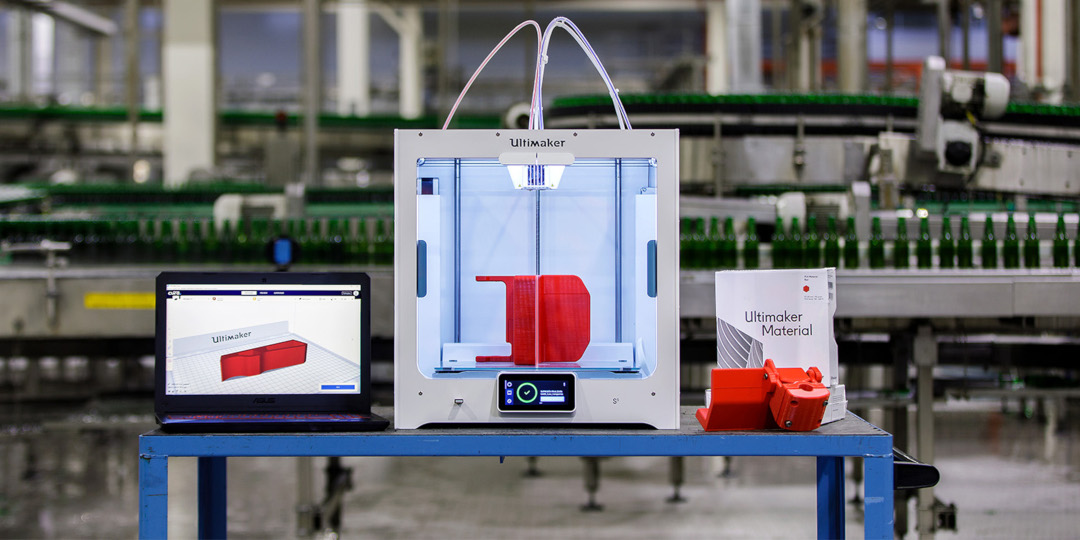

Internationally renowned brewery Heineken gave us a glimpse of how 3D printing transformed its manufacturing line. By implementing the technology, it was able to increase uptime and efficiency at its Seville brewery.

Killa Design, a Dubai-based architectural firm, also showed how it uses 3D printing to create unique, iconic designs – as well as one of the most complex structures ever built.

And it doesn’t stop there. Companies around the world are continuing to introduce 3D printing into their day-to-day operations, taking control of every step of their streamlined workflows – the above examples are but a drop in the bucket. Want to learn more about how companies are shaking up industries?

Summing up and a look ahead

“For Ultimaker, 2019 was an extremely productive and exciting year. We moved to a beautiful new location in Utrecht, celebrated the 100th material on our Marketplace, and saw a dramatic increase in Cura usage,” Paul Heiden, Ultimaker’s Senior Vice President of Product Management, said. “We also worked with Schubert to publish one of the 3D printing industry’s first cases on distributed manufacturing. As we look ahead to 2020, we hope to further our progress in the development of distributed manufacturing – and continue to accelerate the world’s transition to digital distribution and local manufacturing.”

The coming year is sure to bring even more news, stories, and industry advancements. Want to stay up to date with everything that occurs? Subscribe to the Ultimaker newsletter!