New research has prompted an important question: Do all the benefits of in-house 3D printing come at the cost of indoor air quality?

As a 3D printer manufacturer, product safety is one of Ultimaker's highest priorities. So, with a team of independent researchers, we carefully investigated the question and found a number of answers.

For example, it's widely agreed among scientists at the German and Dutch centers for health and safety that based on current knowledge extended exposure to ultrafine particles (UFPs) emitted from 3D printers is safe up to a certain concentration limit:

40,000 UFPs per cubic centimeter

By knowing this and understanding the factors that affect indoor air quality below, you can 3D print with greater peace of mind.

So what are the factors?

1. Your room's dimensional volume

To calculate the dimensional volume of your room, simply multiply its width, length, and height. This is key to the question of particle concentration, because the bigger the room, the more air, and the lower the concentration of emitted particles.

For example, it's safe to print with Ultimaker materials on any Ultimaker 3D printer under recommended conditions.

Those conditions require using one 3D printer in a room that's 30.6 m³. (E.g. a room that's 3.12 m in length, width, and height.) The room's air exchange rate also needs to be 1.8 changes per hour.

2. Your room's air exchange rate

Air exchange rate is also known as ‘air changes per hour’. It's a measure of the volume of air added or removed from a room, divided by the volume of that room.

A baseline air exchange rate of 1 means that 63.2% of the room's old air is replaced by new air each hour. The higher the value, the better the room’s air quality.

Of course, that's as long as the new air is clean and mixed continuously and thoroughly with the old air.

When 3D printing with multiple machines, it's best practice to have good ventilation and a high air exchange rate

3. How many 3D printers you are using at the same time

If one 3D printer can be the source of a certain concentration of UFPs and volatile organic compounds (VOCs), using more than one printer creates an increased concentration.

It might be tempting to think that, for example, two 3D printers create double the UFP and VOC concentration. But with so many other factors that influence air quality, it's not that simple. However, multiple printers do create an increased emission rate which should be taken into account.

4. What material(s) you're 3D printing

As they are heated and extruded, different thermoplastics emit different concentrations of UFPs and VOCs.

This is often related to the nozzle temperature required to 3D print the material. For example, extruding Ultimaker PC (polycarbonate) requires a nozzle temperature of 270 °C and emits a higher concentration of UFPs than Ultimaker PLA which requires only 200 °C.

A polymer's chemistry is also a reason why 3D printing with one material might create higher emissions than another. ABS stands for acrylonitrile butadiene styrene. Its chemical makeup emits VOCs at a higher rate than many other polymers – even at the same temperature.

The same can be said about composite materials. Because they are reinforced with additional glass or carbon fibers, their particles can become airborne, resulting in higher particle emissions.

Some materials affect air quality more than others, so it's always good to check the manufacturer's datasheets

5. How long you're 3D printing for

Your print job's duration will cause the emission of different levels of UFPs and VOCs.

Although that might sound obvious, the relationship between particles emitted and time is not necessarily linear. For example, a 12-hour print won't emit 4x the particle concentration of a 3-hour print.

From our research, we found that emissions often peak at the start of the print, when the polymer is being quickly heated and melted. But this again also varies between different materials.

6. Whether there are other emission sources in the room

It's not only 3D printers that can emit UFPs and VOCs in an office environment. There are other sources too. These can include:

Photocopiers

Laser printers

Vacuum cleaners

Cleaning agents

Computers

Citrus fruit peel

And many more...

While peeling an orange might not result in harmful particle emissions, these can all contribute to the overall UFP and VOC concentration and affect indoor air quality.

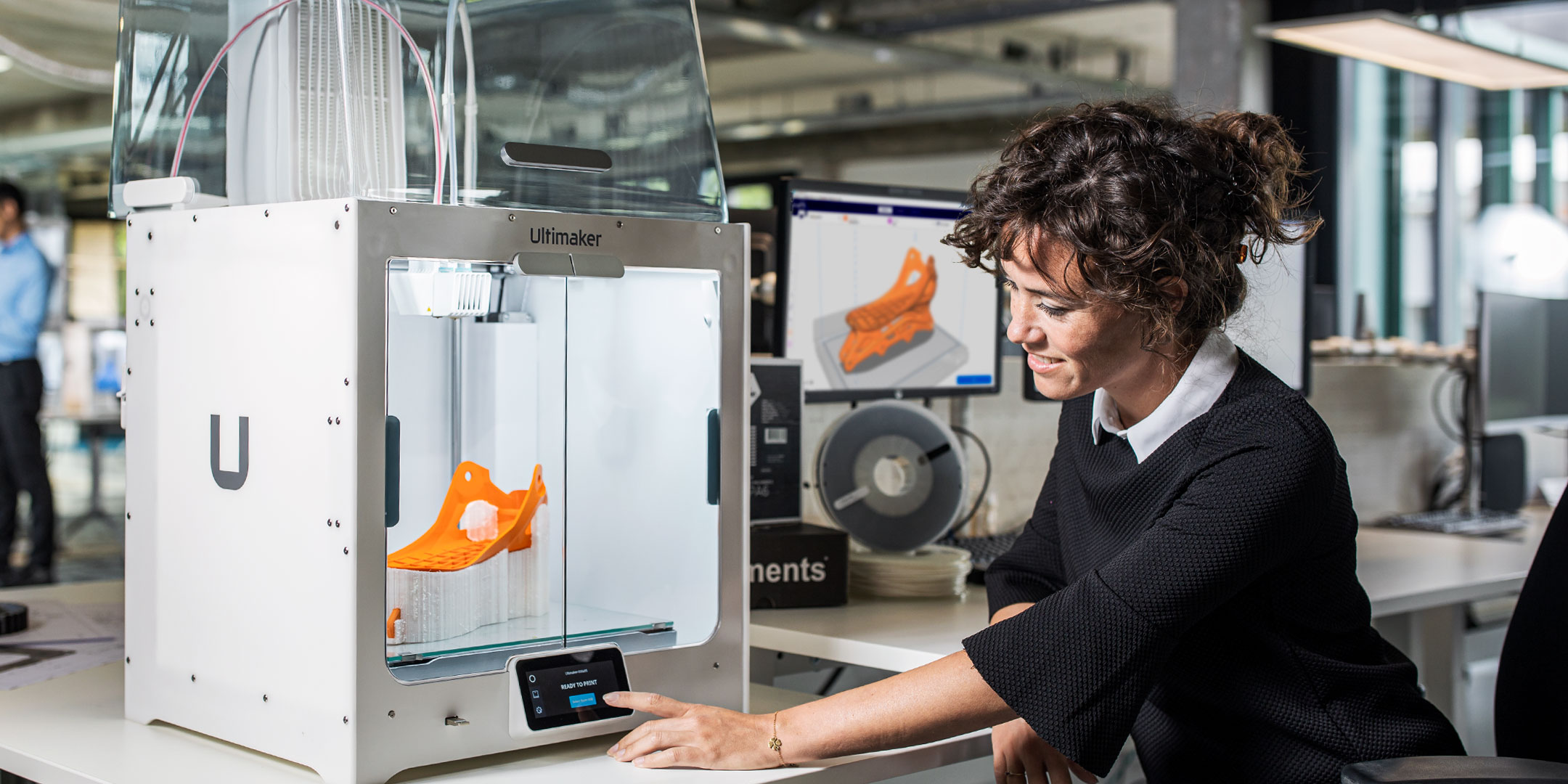

The Ultimaker S5 Air Manager's efficient air filtration provides greater peace of mind when printing with multiple printers or a wide range of materials

Conclusion: 3D print indoors with more confidence

Hopefully that helps to dispel some concerns you might have about 3D printing and air quality.

However, if you want to have more flexibility in your 3D printing setup – 3D printing with more printers or a wider range of materials – the Ultimaker S5 Air Manager as part of the Ultimaker S5 Pro Bundle is now available.

This top enclosure integrates with the Ultimaker S5 to provide a fully validated air filtration solution. It includes a multi-speed fan and EPA filter that removes up to 95% of UFPs – a percentage that's based on data rather than guesswork.

For more information on 3D printer emissions and indoor air quality (including extra details, key definitions, and data from our research), download our free white paper.