When creating a 3D printed object, it’s important to choose the right material. Each offers different benefits, such as heat-resistance, flexibility or high-quality finish, and the type of 3D printing material used can make or break your prototype, tool, or end-use part.

An introduction to 3D printing materials

All 3D printers require material to create a finished product. But with a wealth of materials available, knowing which one to choose can be bewildering. Your choice largely depends on your requirements, which you should identify before you begin.

This guide outlines the most popular 3D printing materials, their properties, and how they can benefit your business.

Material properties to consider

All 3D printing material types have different properties. Broadly speaking, they are divided into three categories:

Aesthetic

Technical

Processing

If you are creating visual aids you will likely prioritize good aesthetics. A business printing end-use parts, however, may value technical performance over appearance.

A 3D printed prototype created by Idea Reality

The following are some of the most important properties materials can determine in your print:

Good surface quality. When presenting concepts to clients (as Killa Design does with its architectural 3D printed models), a high-quality surface finish is vital

Low shrinkage. Shrinkage can be an issue during printing. A material that is shrink-resistant means that dimensions are better preserved – this is important for precision tooling Ultimaker Tough PLA blends technical performance with minimal shrinkage

Toughness and durability. A company like Gerhard Schubert GmbH, which uses 3D printers to create tools for its packaging machines, values durability above all else. End-use parts must be tough and able to withstand repeated use

Thermal resistance. Heat resistance is beneficial for companies making prototypes, as it offers greater design freedom

High tensile strength. Materials sometimes need to withstand high levels of tension. High tensile strength is important for these types of tools

Chemical resistance. If an object will regularly come into contact with chemicals, it must be able to withstand their effects

Ease of use. When creating tools, it’s imperative that materials that print parts first-time right – and that those parts are not susceptible to atmospheric conditions

Flexibility. Some products need to have flexibility to properly function properly (and to not snap under pressure)

Electrical resistance. Although this is a less common requirement, some companies need materials that insulate electricity – or prevent the discharge of static electricity – for safety reasons

3D printed architectural models created by Killa Design require a high-quality surface finish

Different types of 3D printing technology

Technology also plays a part in determining the proper 3D printing material for you. Here’s a brief rundown of the main types of 3D printing technology – and the materials best suited for them:

Fused filament fabrication (FFF). This form of 3D printing uses thermoplastic filaments such as PLA, TPU, PET, and ABS

Stereolithography (SLA) and Direct Light Processing (DLP). These use light to print, and therefore require photopolymer resin

Selective laser sintering (SLS). SLS uses thermal energy to fuse powder particles inside a build area. As such, thermoplastic powders are best (i.e. different types of nylon).

Material Jetting (MJ) and Drop on Demand (DOD). As these use droplets of material, the material needs to be photopolymer resin

Binder Jetting (BJ). Binder Jetting uses a print head to drop binder droplets on a powder surface. The best materials to use are sand or metal powder

Direct Metal Laser Sintering (DMLS), Selective Laser Melting. This adds metal powder as the finished object is being printed. It requires aluminum, stainless steel, or titanium

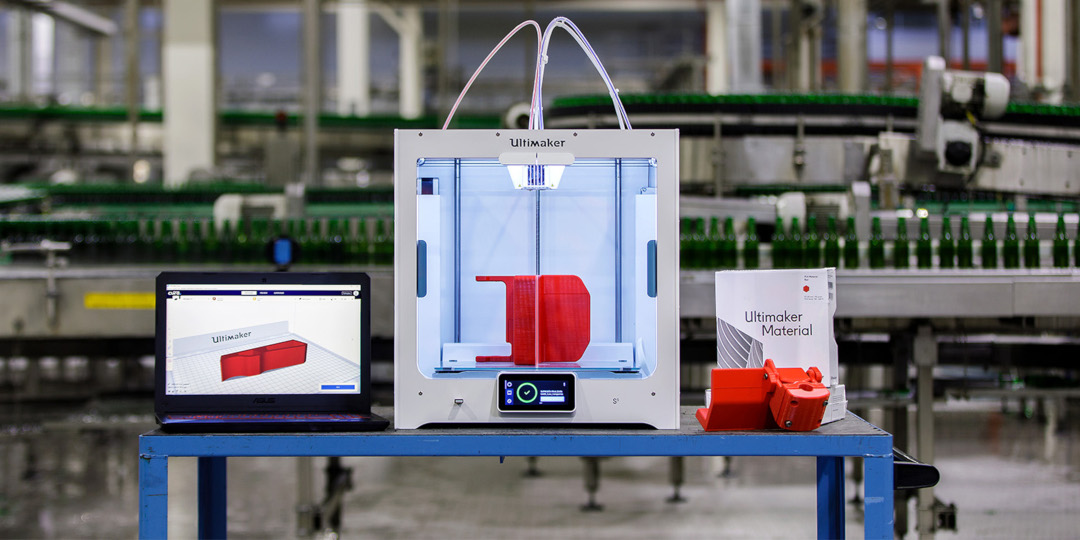

Ultimaker 3D printers use FFF technology to create parts

Materials per industry

Common 3D printing materials also vary from industry to industry. The following is a list of some sectors that use 3D printers, and the materials they favor:

Architecture. Aesthetics is a key concern for architects like Make Architects, especially when presenting 3D designs to clients. A material such as PLA is a good option, as it offers a glossy, attractive finish, and prints in a high resolution

Automotive. The automotive industry often requires quick, easy prototyping, plus printed tools and end-use parts suitable for a factory floor. Robustness and high tensile strength are key, followed by thermal resistance – and sometimes chemical resistance. ABS is a popular choice, as it’s easy to use, strong, and can withstand some heat

Consumer goods. Consumer goods businesses must often test multiple iterations of a product before committing to a final design. Easy-to-use materials such as PLA or versatile ones such as nylon are ideal

Industrial goods. Industrial goods usually need to be strong, flexible, and resistant to breakage. Heineken’s 3D printed production line tooling is an example of this. Some companies may favor materials such as CPE (which has a high tensile strength) or PC (for its exceptional strength)

Different types of 3D printing materials

There are several types of 3D printing material. Below is a list of Ultimaker's 3D printing materials used in many common applications. But with new materials being developed all the time, the choice is almost limitless.

ABS (Acrylonitrile butadiene styrene). ABS is suitable for prototyping and fit testing, making it a popular choice for industries including aviation, automotive, and industrial product development. Its properties include:

Durable

Thermal resistance (up to 85°C)

Good mechanical properties

Adversely affected by UV light

CPE (co-polyester). CPE is as strong as ABS, but odorless. It’s popular material for industrial use (prototypes, tooling, etc.). Its properties include:

CPE+ (co-polyester). CPE+ is stronger than CPE and has greater heat resistance. This makes it even more suitable for industrial purposes

Nylon (polyamide). Nylon can be used to print tools, prototypes, and end-use parts. It’s popular across a wide range of industries, due to its reliability and ease of use. Its properties include:

PC (polycarbonate). Favored by engineers, PC is one of the toughest materials available. It’s ideal for making molds, lighting, short-run manufacturing, and engineering parts. Its properties include:

Tough

Stable in UV light

Heat-resistant

Dimensionally stable

Chemical-resistant

Flame-retardant

PLA (polylactic acid). PLA is aesthetically pleasing, and useful for creating visualization aids and concept models. Architects often choose PLA. Its properties include:

PP (polypropylene). PP is popular, with a wide variety of sectors using it to create prototypes and end-use parts. Its properties include:

TPU 95A (thermoplastic polyurethane). This semi-flexible material is useful for businesses that require a rubber-like effect for prototypes or end-use parts. Its properties include:

If you’d like to find out more about the 3D printing material types, please explore Ultimaker’s three-part materials series.