Leveraging MFFF for personalized parts

Owner and driver, Erik Schwartz is an engineer by trade and spends all of his free time tinkering and maintaining his vehicle to compete in the Championship Off Road Series. Adept at turning his ideas into reality to make improvements, Schwartz makes use of UltiMaker 3D printing technology.

Once considered a novelty, 3D printing has become a necessary tool for this team to compete at a high level. With advanced material options available with the UltiMaker S5, Schwartz Off Road Motorsportz (SORM) is saving time on and off the track.

Challenge

Each year, Schwartz Off Road Motorsportz builds a new one-of-a-kind SxS Pro Mod race car from scratch. In their latest car, they use a custom mount for attaching an electric paddle fan to the radiator.

While the part was previously 3D printed using a Carbon Fiber Nylon material, the engine bay temperatures were at the upper edge of what that material could handle.

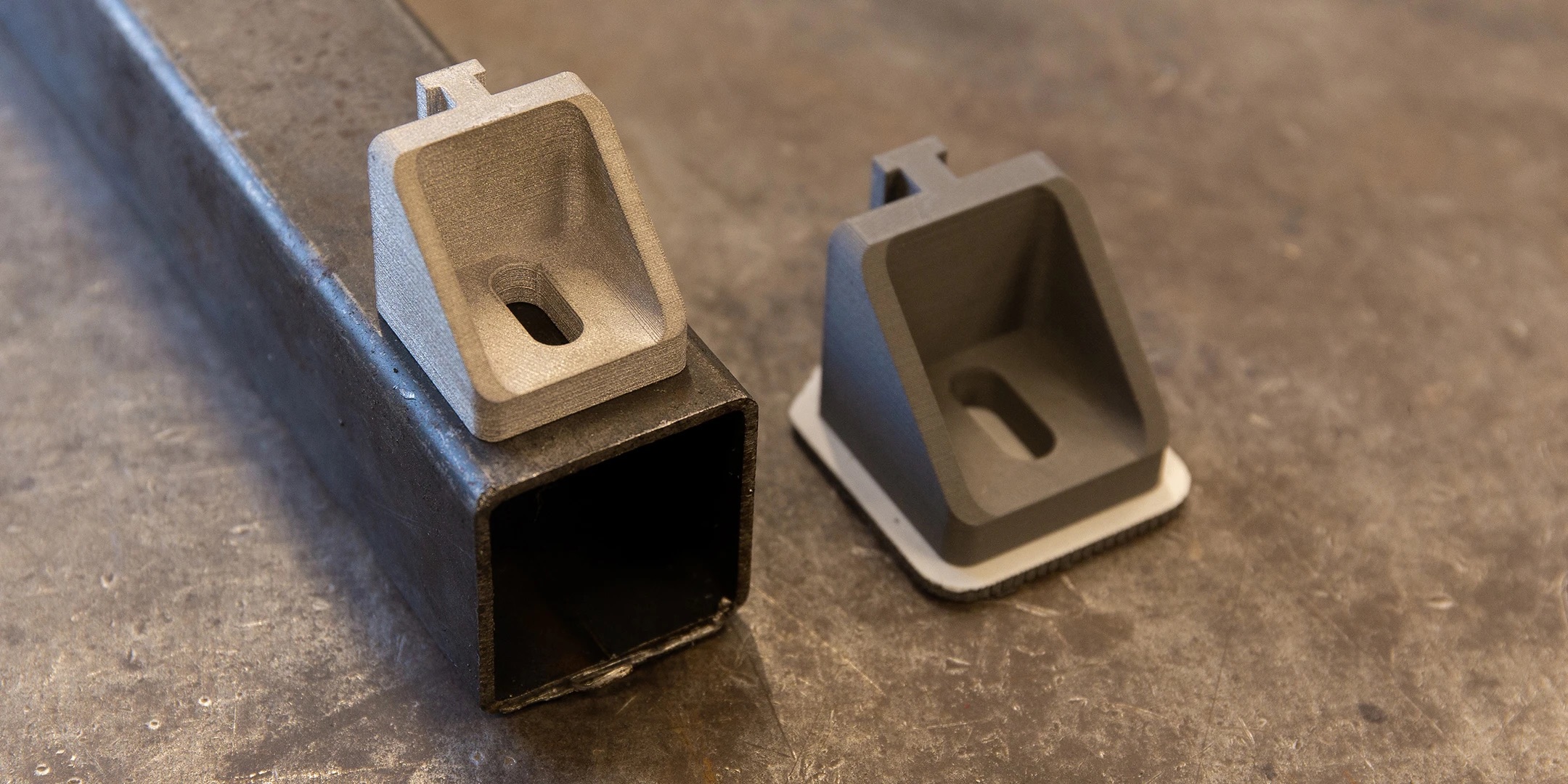

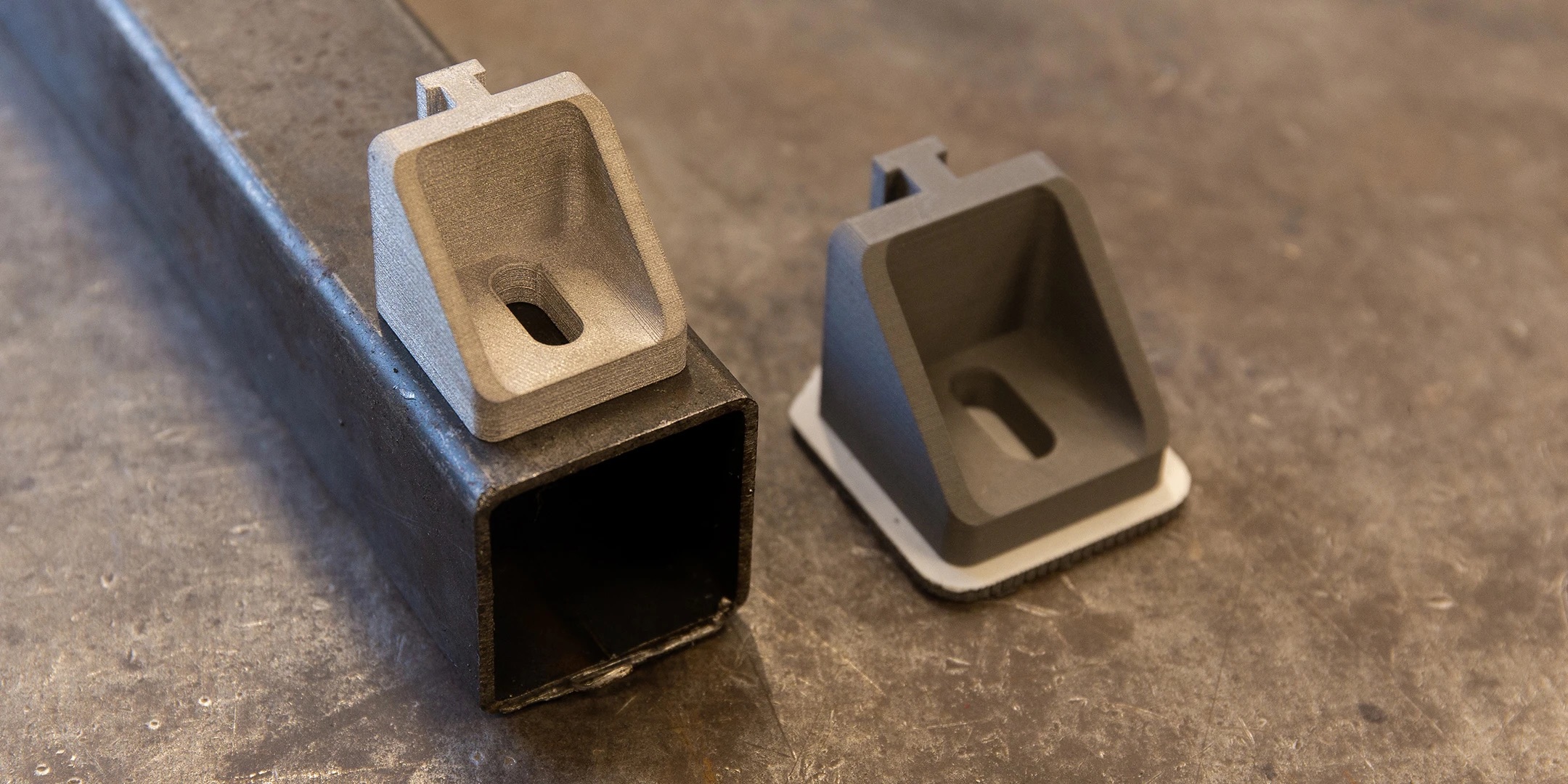

The paddle fan mount metal 3D printed part before and after debinding and sintering

Solution

A new mount was printed using BASF Forward AM Ultrafuse® 17-4PH. This metal material not only met the temperature requirements but also provided the strength required for it to be torqued down tight, allowing it to withstand the demands of a race.

The new mount design includes a custom profile that perfectly matches the OEM mounting points on the paddle fan house, allowing it to slide snugly into the fan. The other side of the mount uses a slot, which enables the inserted mount to be adjusted to match the custom holes that Schwartz Off Road Motorsportz designed into their engine.

Stronger and more temperature resistant, the new metal 3D printed part can better withstand the demands of the race.

| Print time |

Weight |

Cost |

| 4 hours 30 minutes |

154 g |

$22.92 |

Results

The new part is not only more reliable due to its improved temperature resistance, but it is also customized. Meaning it can be more easily adjusted to meet the requirements of the one-of-a-kind car designed by Schwartz Off Road Motorsportz.

From plastic to metal 3D printing

Schwartz Racing is one of many companies realizing the difference metal 3D printing can make in their production.

Click below to explore more MFFF applications stories. Or discover how to buy the UltiMaker Metal Expansion Kit for yourself.

← Explore more metal applications

Meet the Metal Expansion Kit