Native Union used their Ultimaker 3 to rapidly prototype parts and mechanisms for their latest device – the Eclipse. This innovative product resolves a common 21st century issue, making messy USB charging cables a thing of the past.

Native Union, founded in 2009 by John Brunner and Igor Duc, creates tech accessories designed to enhance the user experience, using the highest quality materials. To get the products to market, rapid, cost-effective prototyping is essential – which is where Ultimaker comes in.

What is the Eclipse?

The Eclipse, which features parts and mechanisms prototyped on an Ultimaker 3 printer, is a 3-port USB hub, designed to manage cables and streamline the user’s gadget charging experience. It also offers faster charging, an extra range for added convenience, and a sophisticated, sleek design.

How does it work?

The ingenious design lets users plug up to three USB cables to charge at once. It features a cable management system which prevents tangling, and stores up to 24 feet of cables in total. To get going, all users need to do is plug in their USB charge cables into the device, then plug the Eclipse directly into the wall.

“We’re still very much in the cable era,” says Igor Duc, the co-founder and CEO of Native Union. Although the device isn’t fitted with a wireless charging coil, they designed the Eclipse to offer optimum support for wireless charging mats.

Testing the product with the 3D printing technology

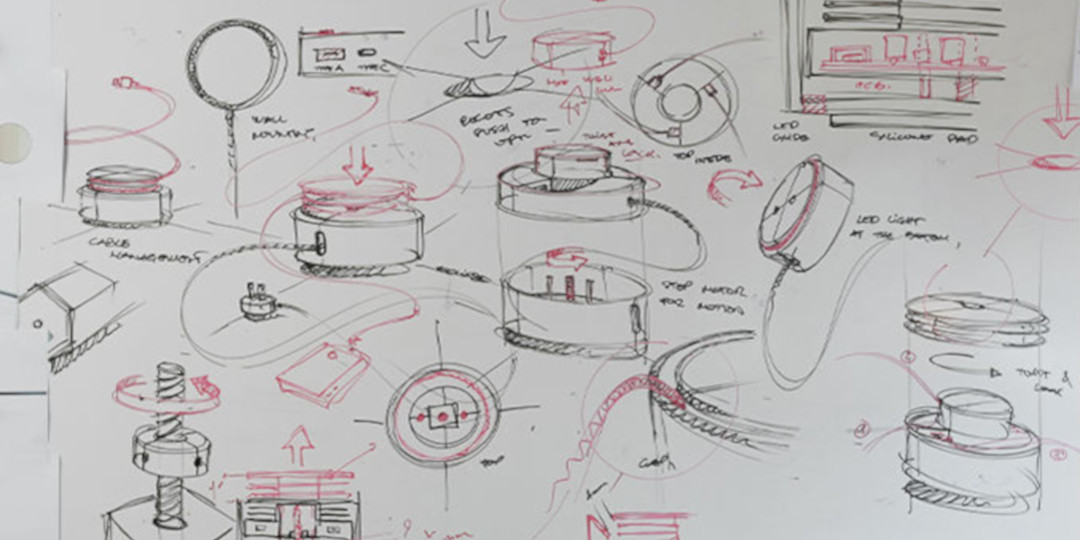

“We used 3D printing to test some of the internal parts and mechanisms,” Igor tells us. “It was a great way for us to rapidly try new ideas.” By being able to experiment with multiple iterations, Native Union could swiftly identify which designs worked and which didn’t – something that couldn’t have been achieved without an in-house 3D printer.

The 3D printing allows us to speed up the process of refinement, and aids in making some tough design decisions, therefore improving the final result.

Why Ultimaker?

The team selected Ultimaker because of its speed and quality. They also found that the software and hardware were user-friendly and intuitive and that the materials matched their requirements well.

Native Union used both PLA/PVA and TPU/PLA combinations to create their prototypes, as they best matched the properties of the materials for the final product. However, they’re considering experimenting with other printable materials in the future and are “very excited about the advancements in printable material technology.”

The company remains focused on developing cutting-edge technological aids and wants to keep enhancing how people interact with their tech devices. Their Ultimaker 3 printer gives them the power to keep building and tweaking prototypes, giving them better insight into the products they’re designing, and helping to inform their design decisions.

We were extremely happy with the quality and the print managed to bring out much of the necessary detail within the model.

Driving innovation through collaboration

Ultimaker has an extensive global network of partners, who are fully certified and trained by our team at HQ. This ensures they offer the highest level of support to all our customers, no matter where they’re based.

For companies like Native Union who are looking for manufacturing or prototyping solutions, our local partners are invaluable. In Native Union’s case, it was 3D Mart in Hong Kong who helped them take their innovative product to the next level, in the quickest, easiest way possible. Thanks to 3D Mart’s tailored 3D printing solution, Native Union was able to design without limitation – which shows just how invaluable collaboration really is!

Our local partners are here to help at every stage of the journey – from identifying the right products for your requirements to maintenance and troubleshooting.

We love Native Union’s useful, minimalist accessories. You can view all their great products on their website. If you’ve got any questions, or want to make a suggestion for our next 3D printing story, get in touch by joining our online community – we love hearing from you!