3D printing benefits many businesses in varying industries and sectors. The technology – also known as additive manufacturing – is a fast, easy way to create prototypes in-house, and to manufacture tools and end-use products.

The ability to print multiple iterations of a part results in a more informed approach to a final design – often at a greatly reduced cost. 3D printing can also be used to educate students in schools, and even enhance some medical practices.

What are the benefits of 3D printing?

One of the best aspects of 3D printing is its versatility. Businesses can achieve a range of different results, depending on the material and type of printer used.

For example, an engineer may want to create a specific tool for his or her machine. By selecting a material that’s durable and heat-resistant, with a high tensile strength, the engineer can print a finished product that perfectly matches his or her needs perfectly.

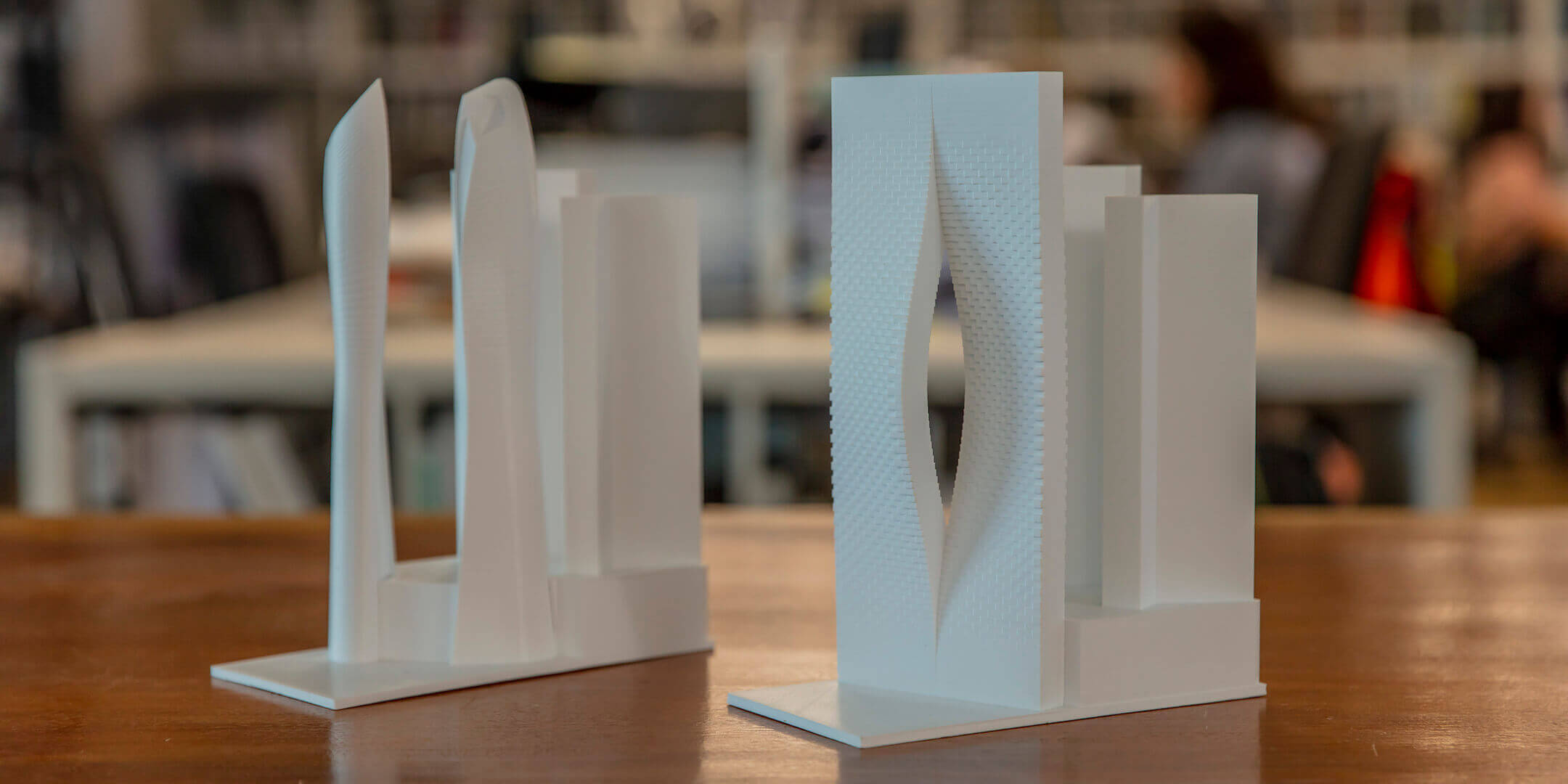

Alternatively, companies like architectural firm Killa Design can demonstrate complex building designs to clients by printing with materials that offer a top-quality finish and high resolution (for including small details).

3D printed architectural models by Killa Design

3D printing benefits per technology

Material choice isn’t the only thing to consider when 3D printing. The type of technology will also determine the results you generate. Here’s an outline of some of the more commonly used technologies and their advantages.

Benefits of FFF

FFF (fused filament fabrication) printing enables users to print with a wide variety of materials, which is handy for those who want to create more than one type of printed item. It’s also cheap, easy to use, and simple to scale-up – something that SMEs appreciate.

Benefits of SLA

An SLA (stereolithography) printer uses a laser to accurately print with resin. The advantages of 3D printing with SLA is that intricate items can be created with ease. This is useful for printing complex engineering parts or making consumer goods, such as jewelry.

Benefits of SLS

SLS technology works by fusing a powdered raw material, typically a polymer. With SLS, finished parts have relatively high mechanical properties in all directions (isotropic mechanical properties).

Benefits of material jetting

Although material jetting does have some drawbacks, it’s prized for its ability to produce an exceptionally smooth finish using liquid resin. This is ideal for companies printing end-use consumer goods, for example.

If you want to know more, read our full guide to different 3D printing technologies.

Benefits of additive manufacturing

More generally, one of the major benefits of all additive manufacturing technologies (in ecological terms) is the reduction of waste. Material is added instead of removed, which means you only use what’s needed. It’s regarded as one of the most cost-effective ways of prototyping in-house, and greatly improves workflow efficiency.

One of the main applications of 3D printing is prototyping products, like these BOSEbuild headphones

3D printing benefits per industry

Several industries have already identified the advantages of 3D printing. Here’s some insight into how they’ve used the technology to enhance their practices.

3D printing benefits in manufacturing

The technology enables companies to create 3D printed tools, jigs, and fixtures in rapid succession. This means machinery can be set up more quickly, variation is reduced during fitting and assembly, and production processes are more streamlined. By using tough, impact-resistant materials such as ABS or CPE, businesses like Ford can print tools fit for a busy production line, whenever they’re required.

3D benefits in product development

Many businesses benefit from 3D printing prototypes. Designs can be evaluated quickly, functional prototypes make it simple to test out usability in practical terms, and feedback can be swiftly obtained from the target market. It also means that products are brought to market far more quickly. BOSE used 3D printing in the product development process, creating multiple prototypes of its headphone sets.

3D printing benefits in education

Teachers and lecturers use 3D printing to explain ideas and enhance their students’ understanding. Students can also experiment and explore with 3D printing, testing out theories and refining concepts. Sometimes, materials that offer plenty of detail will be suitable – such as PLA. Alternatively, a material like nylon may be more appropriate, as it’s easy to use and produces reliable results. Here’s an example of how the Metropolitan Museum of Art tapped into the technology’s potential.

3D benefits in architecture and design

One of the advantages of 3D printing is that companies can create models of their designs, either to show clients or to review and refine their ideas. PLA is perfect for printing in greater detail, making it the preferred material for architects. Make Architects, for example, use a farm of several Ultimaker printers to enhance its design process.

3D benefits in the medical sector

3D printing is changing the face of healthcare, whether that’s creating customized prosthetics, or helping to explain surgical procedures to patients with 3D prints. The technology can even be used in dentistry – for example, OpLab uses a 3D printer to create models of dental arches.

Want to find out more about the benefits of 3D printing?