Supply chain shortages. Global trade wars. Virus mutations.

It’s fair to say that the current economic landscape is Volatile, Uncertain, Complex, and Ambiguous. This is the “VUCA” world we are living in, said Ultimaker CEO Jürgen von Hollen during our biannual showcase event.

Doing business in this environment is hard. It means constant change and the need to adapt. But we are convinced that 3D printing can play a key role in enabling many companies and industries to stay flexible. The problem is that most 3D printing systems are locked into a proprietary product portfolio.

What if engineers were able to unlock their creativity – designing and printing almost any application that suits their business goals? What would that allow companies to accomplish?

We believe this is possible through a robust 3D printing ecosystem of trusted partners. Ultimaker is uniquely positioned as a leader in the professional 3D printing segment and provides an open platform that delivers a holistic experience in hardware, software, materials, and services.

Add to that our rapidly growing ecosystem and you have a 3D printing solution that truly empowers businesses to sustain a competitive advantage – despite today's economic climate.

4 ecosystem partner highlights at Formnext

From November 16 to 19 at Formnext, many of our ecosystem partners showed off what they have achieved using the Ultimake platform. Here’s a summary of what’s new with Ultimaker’s ecosystem partnerships:

LEHVOSS Group

LEHVOSS LUVOCOM 3F PAHT® 9825 NT is a high-temperature Polyamide-based material. It's also the first Ultimaker certified material on the Ultimaker platform.

A 3D printed cover with the first Ultimaker Certified Material – LEHVOSS LUVOCOM 3F PAHT ® 9825 NT: a reproducible and repeatable part is the result

Certifying materials has huge benefits. It helps customers safely use materials, machines, and processes for the optimal reproduction of products and parts. It also provides the best experience on an Ultimaker 3D printer. For example, we validated the materials’ print profile, filament, and made sure they fit our workflow – with an NFC chip embedded in the spool for auto-recognition. Plus, certified materials are easily available via the Ultimaker reseller network.

Siemens

Siemens NX is now integrated with Ultimaker’s software platform, combining Ultimaker Cura, the world's most popular slicing engine, with leading CAD/CAM software. This enables you to turn to 3D printing as your go-to manufacturing solution, one which delivers first-time-right results where and when they are needed. For engineers and operators using Siemens NX, this integration simplifies 3D printing processes, enabling them to print directly from existing, established software rather than adding to a tech stack.

Make 3D printing your go-to manufacturing solution thanks to integration with leading CAD/CAM software Siemens NX

Autodesk Fusion 360

A full end-to-end CAD platform, Autodesk's Fusion 360 tightly integrates across dedicated additive manufacturing spaces – such as Ultimaker Cura and Ultimaker Digital Factory. This means that users can now simulate and engineer their work, then seamlessly switch software platforms for granular control over setup, support materials, orientation, slicing, and the creation of STL or 3MF files for printing. Users don’t have to worry about setting up and slicing parts every time they need to make a new print, Fusion 360 will automate that through the additive manufacturing space!

Autodesk's Fusion 360 integration with Ultimaker software automates the crossover between part simulation and print preparation

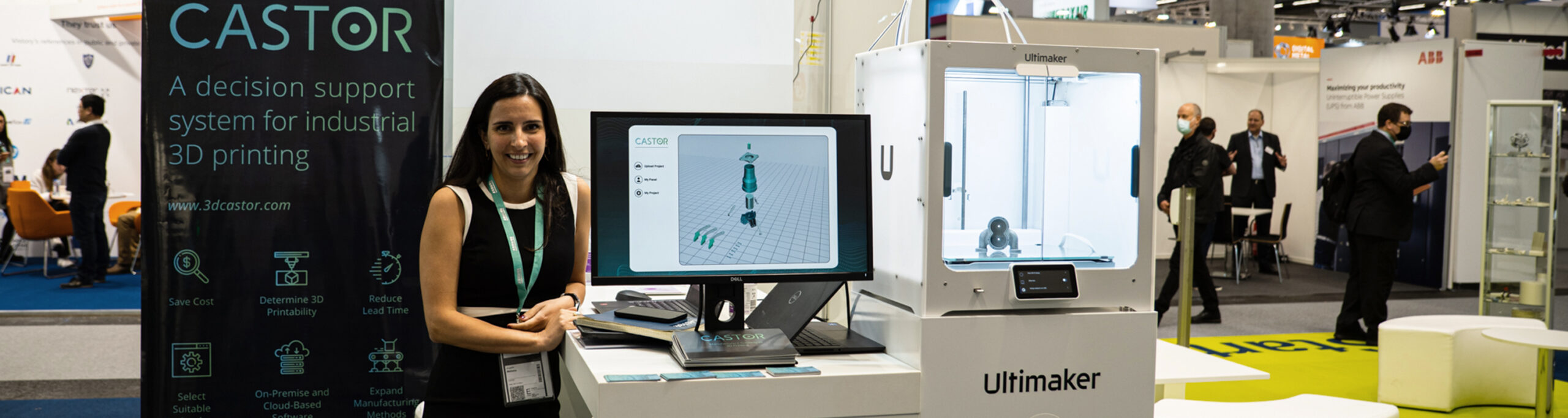

Castor

Castor makes part identification software, which solves the initial problem of finding the right parts that makes sense to 3D print, both technically and economically. They recently developed an integration for the Utimaker Digital Factory, which allows you to directly export parts from Castor to your in-house Ultimaker 3D printer. This saves both time and effort, streamlining the 3D printing process, as there is no need to switch between platforms.

Castor makes it possible to identify the right parts to 3D print and then export them to your printer via Ultimaker Digital Factory

All the Ultimaker ecosystem partners at Formnext

Below is an overview of the ecosystem partners that attended Formnext. Each demonstrated the Ultimaker platform in combination with their software integrations, materials, or hardware.

Software partners

Material partners

Other partners

In addition to these, BASF, Covestro, Kimya, Arkema, Polymaker, Lubrizol, and Twikit also showed joint 3D printing applications marked and printed with Ultimaker.

Together we unlock 3D printing applications

It was a fantastic week to showcase the collaboration happening across Ultimaker's open platform. If you missed the event, click below to check out the growing number of ecosystem partnerships. Despite today's market challenges, together we are sparking 3D printing innovation that keeps businesses ahead.