Where can you see it?

You can view the webinar below:

Unlimited application potential.

Specialized for engineering applications.

High-performance and certified materials

Over 300 materials to choose from.

From polymers to composites to metals.

Ultimaker’s first webinar, “The 3D printing mindset: How to choose the right composite material,” was broadcast on January 22. It is the first in what will become a series of monthly webinars that focus on specific, deep-dive topics that we believe are important to Ultimaker users.

You can view the webinar below:

There, you can register with your name and email address, and immediately begin watching.

Ultimaker Application Engineers Lars de Jongh and Jeremy Evers host the webinar, which runs approximately 40 minutes and includes a live Q&A with Matt Griffin, Director of Community Development for Ultimaker Americas. During the entire webinar, viewers could ask questions via a chat function, download assets such as diagrams and comparison charts, and vote in polls.

The recorded broadcast teaches viewers how to:

Identify high-value applications that would benefit from composites

Make the perfect choice between glass and carbon-fiber

3D print advanced materials with the right settings

Select the best materials for 3D printing end-use parts

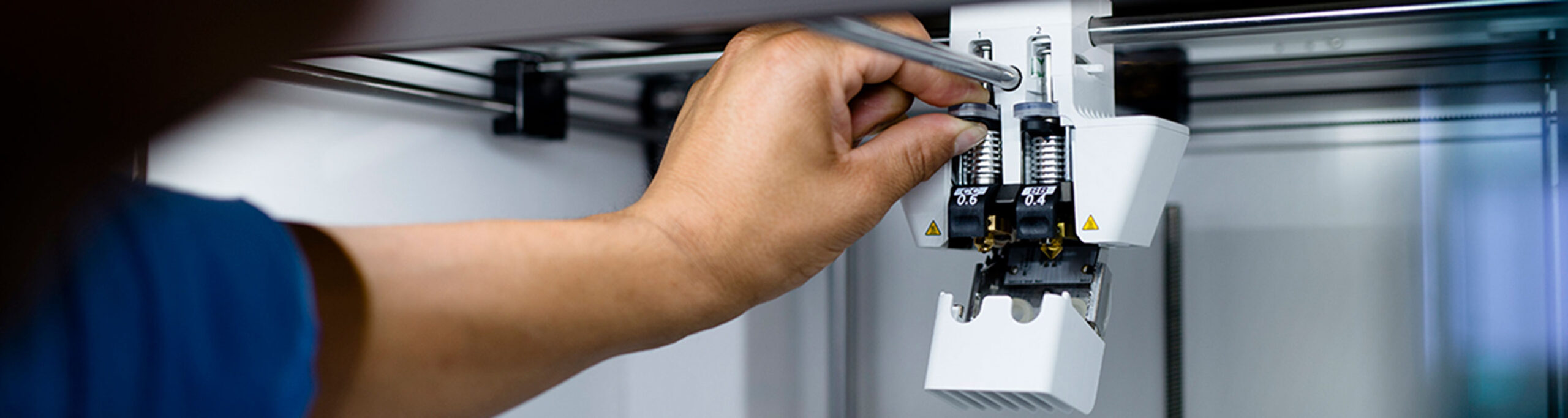

Use dual extrusion to take composite 3D printing to the next level

You’ll also get an up-close look at real-life examples of composite parts that Ultimaker Application Engineers have recently worked on and created for customers.

You really need to have a certain mindset to start off with tackling higher-requirement applications.

In the live Q&A, you’ll learn the answers to questions such as:

Which material would you recommend starting with for your first composite print?

Is there a composite material that makes prints both stronger and more flexible?

What are the key differences between chopped fiber composites and continuous fiber? Why would you choose one over the other?

The next Ultimaker webinar, “The 3D printing mindset: Distributed manufacturing”, is scheduled for February 19, at 10am and 5pm CET. Keep an eye on Ultimaker’s social media channels in the coming weeks for a sign-up link. We look forward to seeing you there!

For more material-related content, check out our blog post comparing glass and carbon-fiber composites, or download our white paper on 3D printing applications. You can visit our Materials page to view various material and their properties, ensuring that you are making the right choice for developing ground-breaking applications.

Want to stay up to date with everything that’s happening at Ultimaker, including all the latest webinar news?

UltiMaker uses functional, analytical and tracking cookies. Tracking cookies enhance your experience on our website and may also collect your personal data outside of Ultimaker websites. If you agree with the use of tracking cookies, click “Accept all”. You can withdraw your consent at any time. If you do not consent with the use of tracking cookies, click “Manage”. You can find more information about cookies on our Privacy and Cookie Policy page.

To monitor the performance of our site and to enhance your browsing experience.

To understand user behavior in order to provide you with a more relevant browsing experience or personalize the content on our site.

To personalized and measure the effectiveness of advertising on our site and other websites.