De naadloze, efficiënte upgrade die uw productieprocessen nodig hebben.

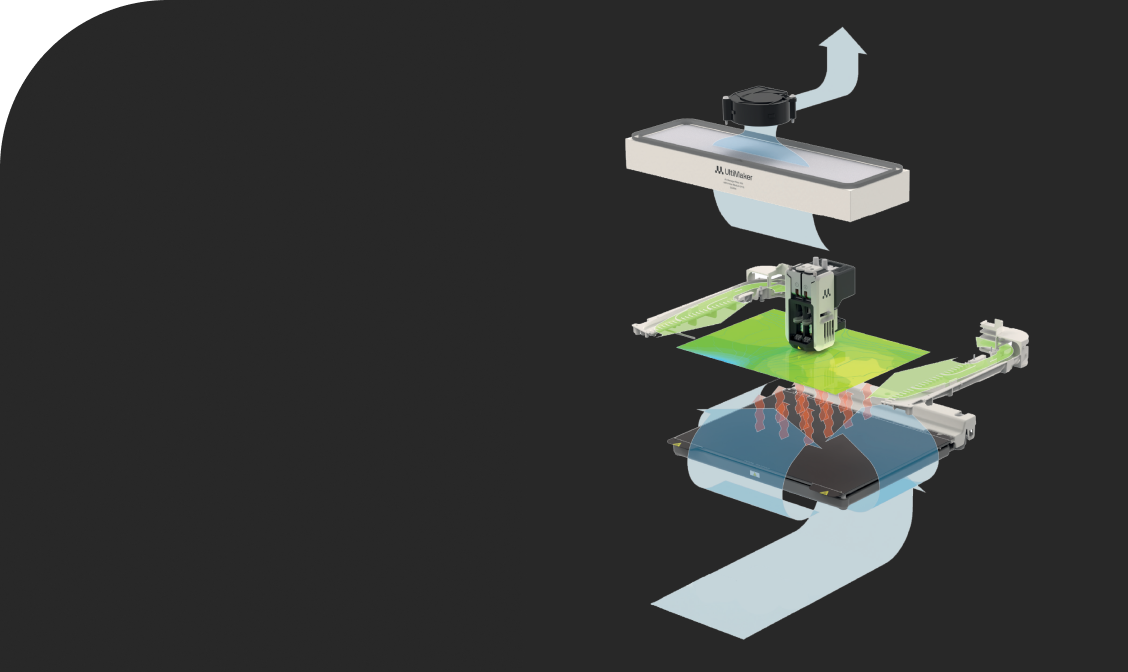

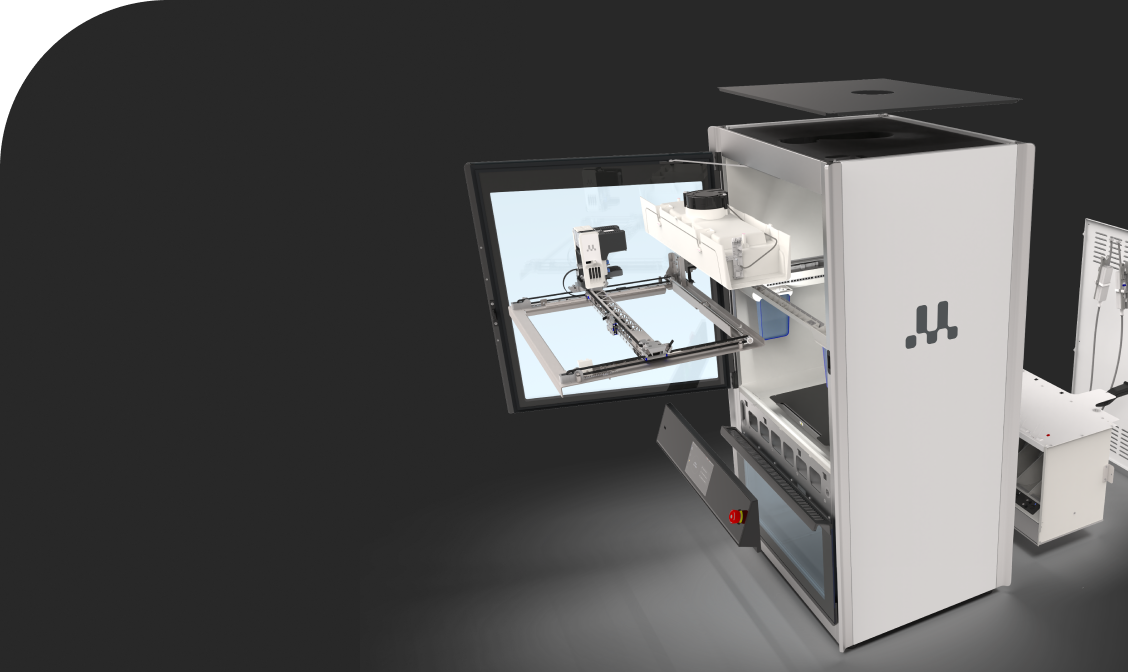

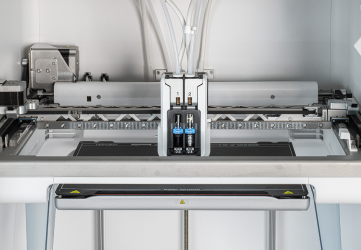

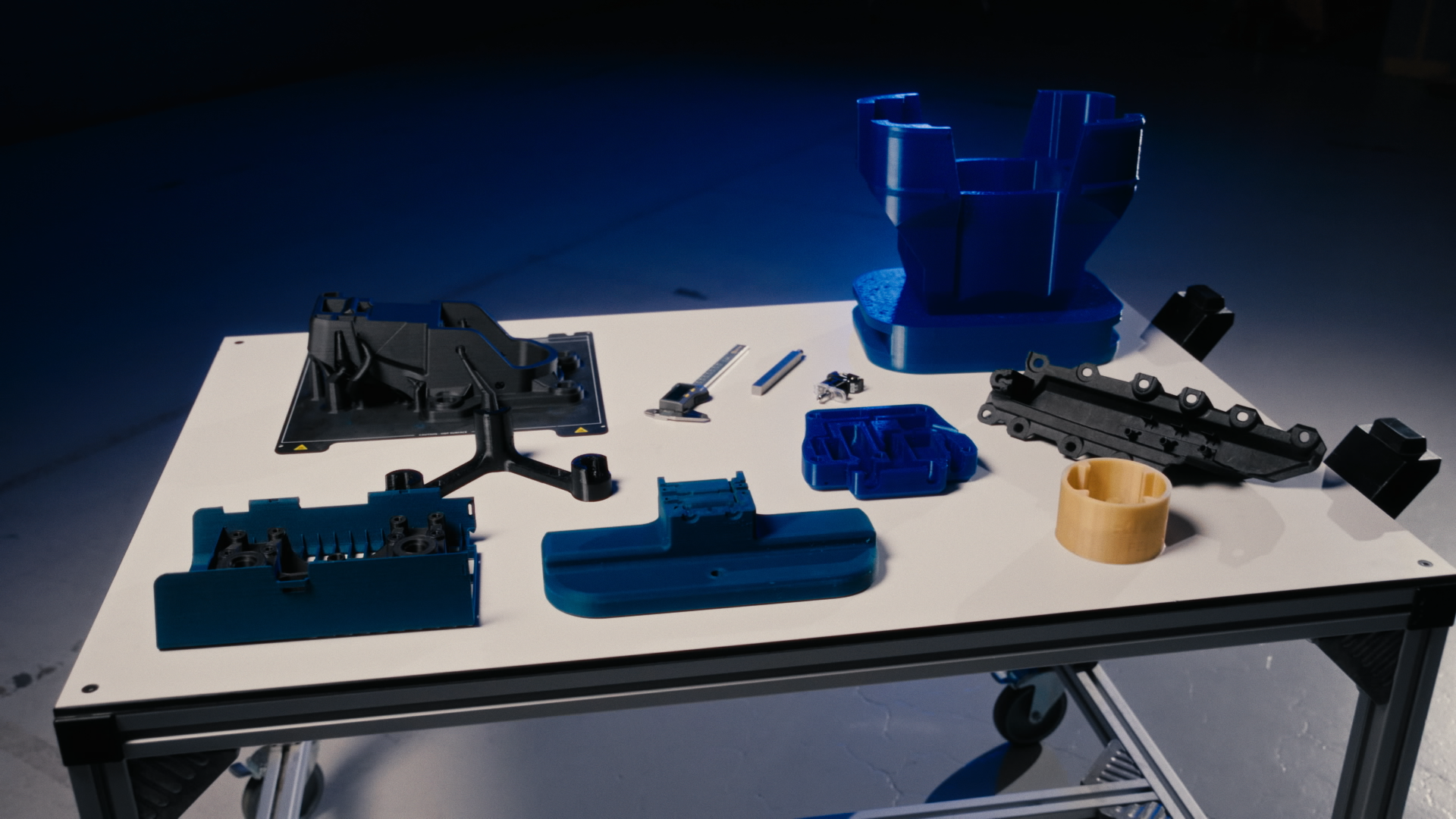

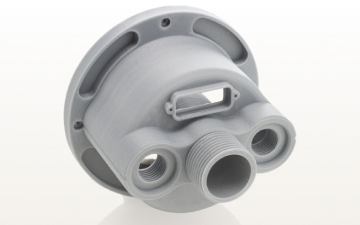

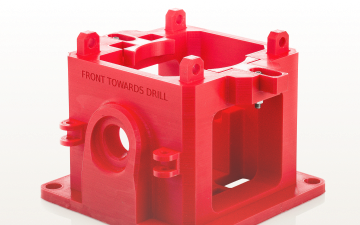

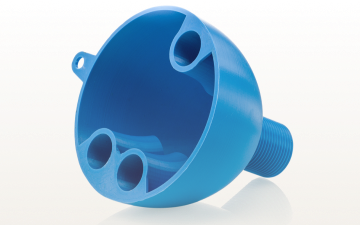

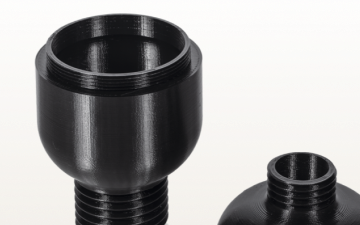

De Factor 4 verhoogt de productiecapaciteit met zijn drievoudig geïsoleerde bouwkamer en directe dubbele extrusie. Het geautomatiseerde systeem voor materiaalbehandeling garandeert de kwaliteit van het filament. Daarnaast zorgt het robuuste, temperatuurgestuurde ontwerp voor een consistente productie-output, zelfs bij complexe en uitdagende ontwerpen.

Heavy duty, heavy weight

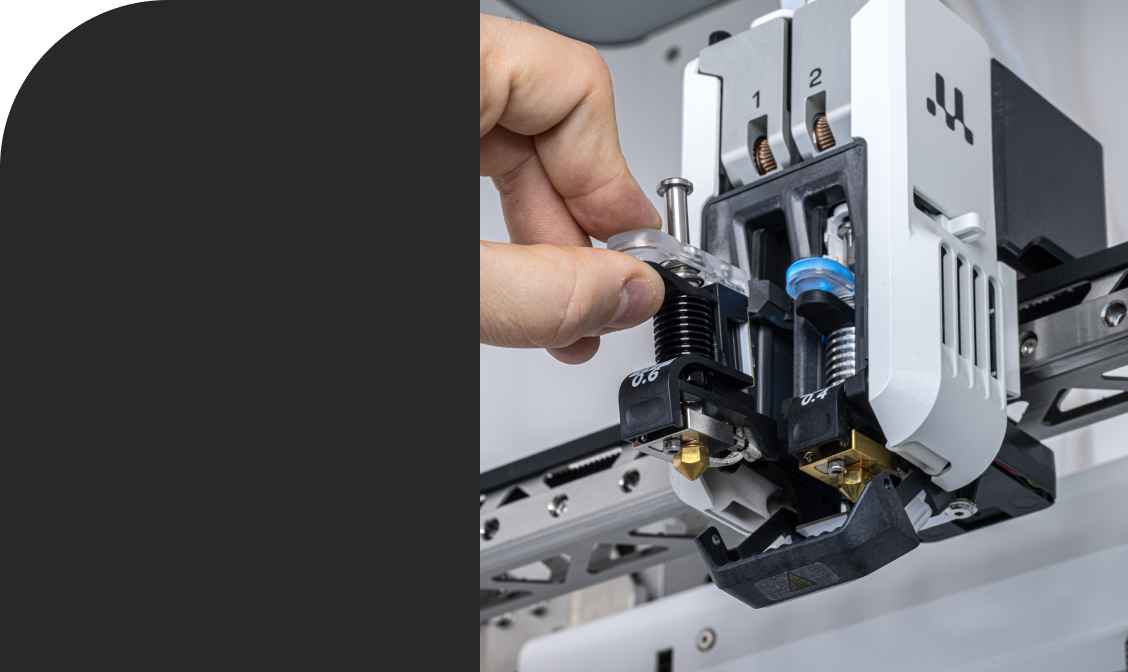

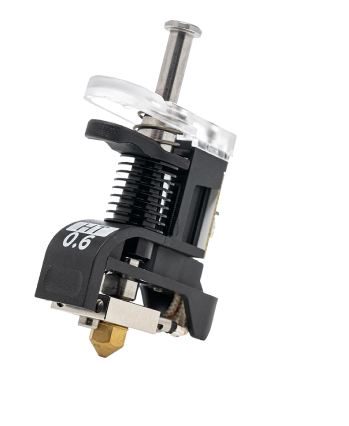

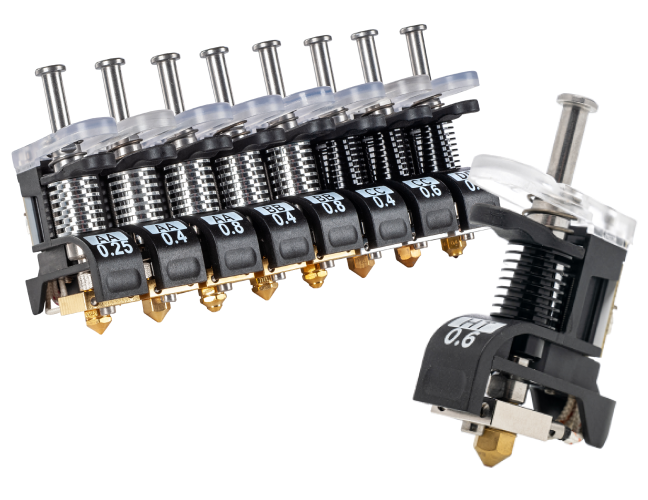

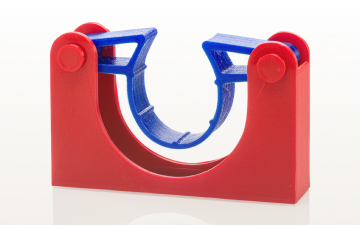

Direct

Dual

Extrusion

effective dual 3D printing