Recycling potential

The recyclability of 3D printing filaments varies widely:

- PET and PETG: These materials are widely recycled in many regions, making them a good choice for environmentally conscious users.

- ABS and Nylon: While technically recyclable, these materials are often not accepted in curbside recycling programs due to their higher melting points.

- Composite filaments: Materials containing additives like carbon fiber or metal powders are generally not recyclable through conventional means.

Some filament manufacturers now offer recycling programs for their products, helping to close the loop on 3D printing waste.

Energy consumption and emissions

The environmental impact of 3D printing extends beyond the filament itself. Consider these factors:

- Printing temperature: Lower-temperature filaments like PLA generally require less energy to print than high-temperature materials like PC or PEEK.

- VOC emissions: Some filaments, particularly ABS, emit potentially harmful volatile organic compounds (VOCs) during printing. Opting for low-emission materials like PLA or PETG can improve indoor air quality.

Read further in our article that deep-dives into 3D printer emissions and air quality.

Emerging eco-friendly filaments

Innovative manufacturers are developing new filaments with improved environmental profiles:

- Recycled filaments: Made from post-consumer or post-industrial plastic waste, these materials give new life to discarded plastics.

- Wood-filled filaments: Combining PLA with wood fibers, these materials offer a unique aesthetic while utilizing renewable resources.

- Algae-based filaments: Experimental materials derived from algae biomass show promise as a sustainable alternative to traditional plastics.

Balancing performance and sustainability

When selecting filaments for environmental sustainability, consider the following:

- Application lifespan: For short-term or prototype parts, prioritize biodegradable materials. For long-lasting functional parts, durability may outweigh biodegradability.

- Local recycling capabilities: Choose materials that are recyclable in your area when possible.

- Print success rate: Failed prints contribute to waste, so selecting a filament that prints reliably can reduce overall material consumption.

Future trends in sustainable 3D printing

The 3D printing industry is actively working towards more sustainable practices:

- Closed-loop systems: Printers that can recycle failed prints or support materials directly into new filament.

- Bio-based engineering plastics: Development of high-performance materials derived from renewable resources.

- Improved energy efficiency: Advancements in printer technology to reduce power consumption during the printing process.

By considering these environmental factors alongside the mechanical and printing properties discussed in previous sections, makers can make informed decisions that balance performance requirements with sustainability goals. As the 3D printing industry continues to evolve, we can expect to see further innovations in eco-friendly materials and processes, driving the technology towards a more sustainable future.

Choosing the right filament for your project

As we have explored the diverse landscape of 3D printer filaments, the next step is to determine how to select the most suitable filament for your specific project needs. This decision-making process involves evaluating several critical factors that influence the final outcome of your 3D printed objects.

Project requirements and filament properties

Understanding the specific requirements of your project is paramount. Consider the following aspects:

- Functionality: Determine whether the printed object needs to be functional or a visual prototype. Functional parts often require filaments with higher strength and durability, such as ABS or Nylon, while decorative items might benefit from the ease of use and aesthetic variety of PLA.

- Environmental Conditions: Consider the environment in which the object will be used. For outdoor applications, materials like ASA or PETG, known for their UV resistance, are preferable. For high-temperature environments, polycarbonate or PPS CF may be necessary.

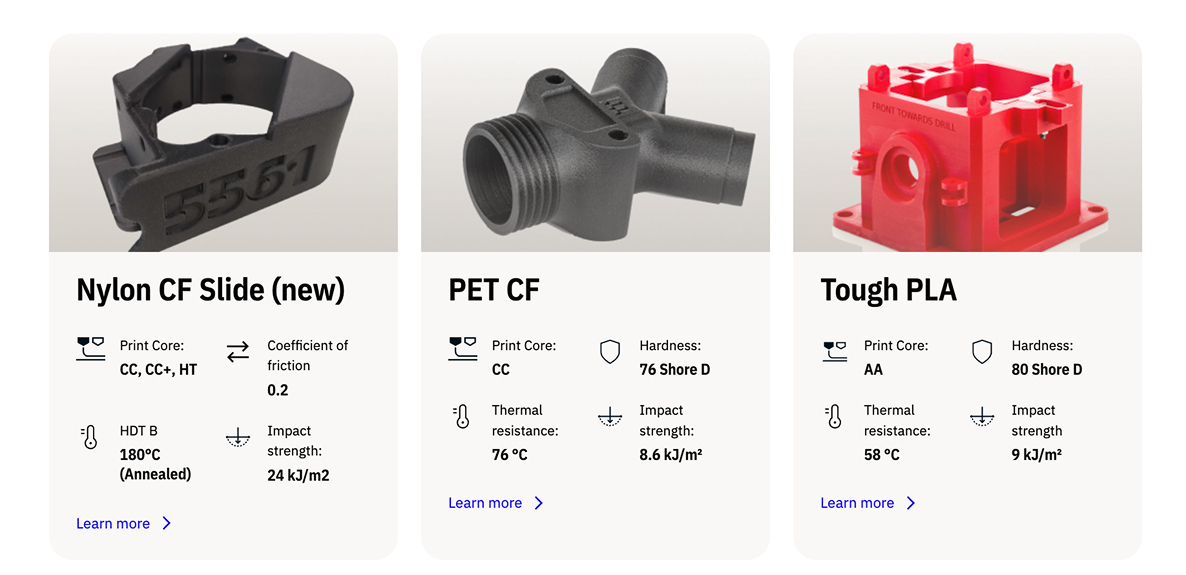

- Mechanical Properties: Assess the need for flexibility, impact resistance, or tensile strength. As discussed in the Filament Strength and Durability section, materials like TPU offer flexibility, while carbon fiber-filled filaments provide enhanced stiffness.

Printer compatibility and technical considerations

Ensure that your 3D printer is compatible with the chosen filament:

- Temperature Capabilities: Verify that your printer can reach the necessary nozzle and bed temperatures for the filament. High-performance materials like PEEK require specialized printers capable of maintaining high temperatures.

- Extruder Type: Some filaments, particularly flexible ones like TPU, perform better with direct drive extruders. Check your printer's specifications to ensure compatibility.

- Build Volume and Bed Adhesion: Consider the size of your print and the adhesion properties of the filament. Materials like ABS may require a heated bed and enclosure to prevent warping.

Cost and availability

Budget constraints and material availability can also influence your choice:

- Cost-Effectiveness: While advanced materials offer superior properties, they often come at a higher cost. Balance the need for performance with budget considerations, especially for large-scale projects.

- Local Availability: Ensure that the filament is readily available from suppliers in your region to avoid delays in your project timeline.

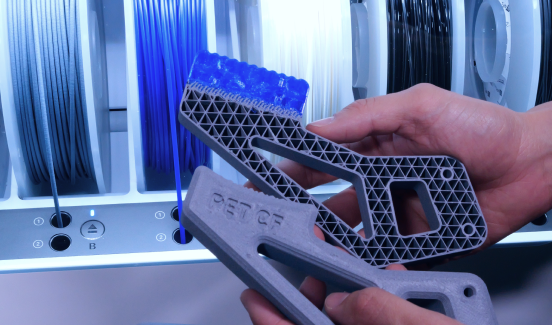

At UltiMaker’s Marketplace, you can find both UltiMaker and third-party filaments to fit your needs.

Testing and iteration

Before committing to a large print, conduct small test prints to evaluate the filament's performance. This allows you to:

- Fine-Tune Settings: Adjust print speed, temperature, and other parameters to optimize print quality.

- Assess Material Suitability: Confirm that the filament meets the mechanical and aesthetic requirements of your project.

Choosing the right filament is a nuanced process that requires a thorough understanding of both the material properties and the specific demands of your project. By considering the factors outlined above, you can make informed decisions that enhance the quality and functionality of your 3D printed objects. As we continue our exploration,

Conclusion and future trends in 3D printing filaments

As we conclude our comprehensive exploration of 3D printer filament types and uses, it's clear that the world of additive manufacturing materials is diverse, complex, and rapidly evolving. Let's recap some key takeaways and look ahead to emerging trends that will shape the future of 3D printing filaments.

Key takeaways

- Material Diversity: From basic PLA to engineering-grade polymers like PEEK, the range of available filaments caters to a wide spectrum of applications and user needs.

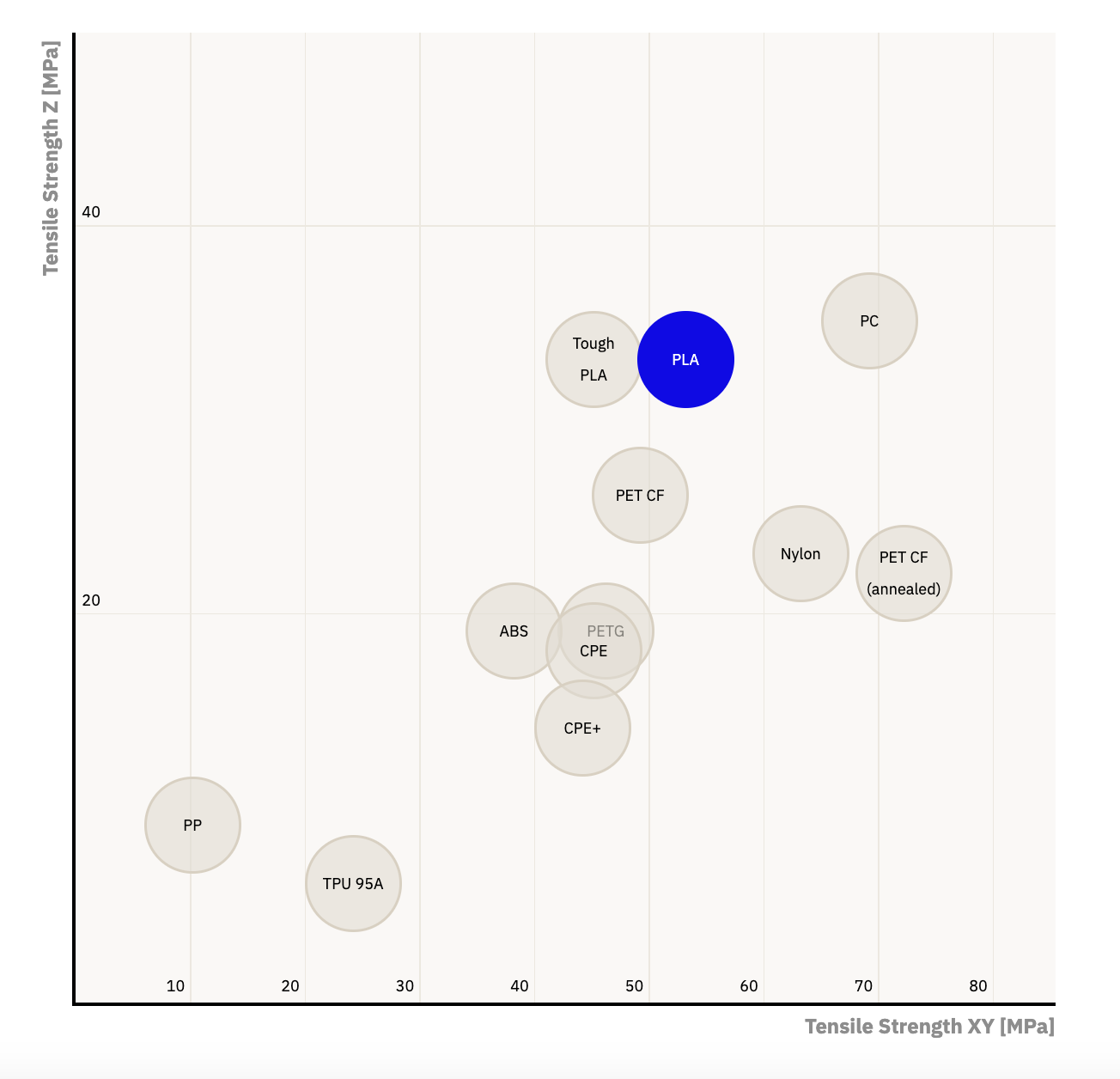

- Property Trade-offs: As discussed in our comparison chart, each filament type offers a unique balance of properties such as strength, flexibility, and printability. Selecting the right material often involves carefully weighing these trade-offs.

- Environmental Considerations: The growing focus on sustainability has led to innovations in biodegradable and recycled filaments, as well as more eco-friendly manufacturing processes.

- Proper Handling: The importance of correct storage and handling practices cannot be overstated, as they directly impact print quality and material longevity.

Emerging trends and future developments

Looking to the future, several exciting trends are poised to shape the landscape of 3D printing filaments:

1. Advanced composite materials

Building on the success of carbon fiber and metal-filled filaments, we can expect to see more advanced composite materials that combine the printability of thermoplastics with the enhanced properties of additives. These may include:

- Nano-reinforced filaments for improved strength and conductivity

- Bio-based composites that blend renewable resources with high-performance additives

- Smart materials that can change properties in response to external stimuli

2. Expanded functional properties

Future filaments may offer enhanced functional properties beyond mechanical strength, such as:

- Improved thermal and electrical conductivity for printed electronics

- Enhanced antimicrobial properties for medical applications

- Self-healing capabilities to extend the lifespan of printed parts

3. Sustainability innovations

The push for more environmentally friendly 3D printing practices will likely drive developments in:

- Fully biodegradable filaments that break down in natural environments

- Improved recycling processes for a wider range of filament types

- Filaments derived from captured carbon or ocean plastics

4. Material-specific printer optimizations

As filaments become more specialized, we may see printers designed to optimize performance with specific materials:

- Advanced temperature control systems for high-performance polymers

- Integrated filament drying and storage solutions

- Specialized extruders for highly flexible or abrasive materials

5. AI-driven material development

Artificial intelligence and machine learning could revolutionize filament development by:

- Predicting optimal formulations for specific property profiles

- Automating the testing and iteration process for new materials

- Generating custom filament recipes tailored to individual print requirements

The world of 3D printer filaments is dynamic and full of potential. As we've seen throughout this guide, understanding the properties, applications, and best practices for various filament types is crucial for successful 3D printing. By staying informed about current materials and emerging trends, makers and professionals alike can harness the full power of additive manufacturing to bring their ideas to life.

As 3D printing technology continues to advance, we can expect filaments to become more specialized, sustainable, and capable of producing parts that rival or exceed those made by traditional manufacturing methods. The future of 3D printing filaments is bright, promising exciting possibilities for innovation across industries and applications.

Innovate with the UltiMaker Ecosystem

UltiMaker offers a complete ecosystem for you to innvoate with additive manufacturing - from certified filaments to industry-grade 3D printers. Whether you need to streamline your workflow, reduce downtime, or explore customized components, 3D printing offers endless opportunities to enhance your operations. Get in touch to discover how UltiMaker's industrial-grade solutions can help push your business forward.