Custom-built, in-house

Traditionally machined from materials like POM, timing screws can be expensive and slow to produce - especially when customized to fit specific product shapes. By switching to in-house 3D printing with UltiMaker Nylon CF Slide, manufacturers can create tailored, wear-resistant screws that meet their exact needs.

The design is even split into two parts for easier assembly and maintenance - no complex tooling or long lead times required.

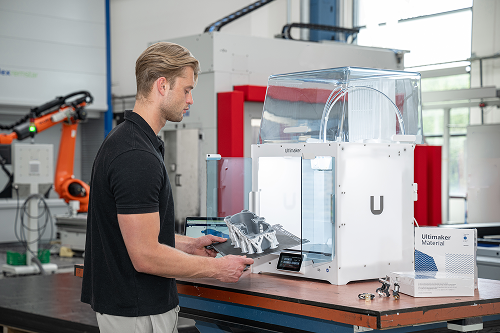

This timing screw was printed on the UltiMaker S6 - our latest professional 3D printer designed for high-demand applications. Powered by the new Cheetah motion planner, the S6 delivers faster print speeds without compromising dimensional accuracy or surface quality. That means teams can move from design to deployment faster than ever, with confidence that every part will perform under pressure.

Results that matter

Switching to 3D printing delivered dramatic efficiency gains:

- €9,901.50 in cost savings

- Lead time reduced by 90% (12.5 days saved)

Built to perform

** Thanks to Nylon CF Slide’s low-friction and high-wear resistance properties, the timing screw is ideal for continuous motion environments. The printed geometry is optimized for smooth product handling, while dual extrusion allows for built-in wear indicators—making proactive maintenance easier than ever.

Faster lines, fewer headaches with UltiMaker S6

This application shows how even highly specialized parts can benefit from additive manufacturing. When you need precision, speed, and durability - UltiMaker has you covered.

The UltiMaker S6 is your most straightforward and accessible entry point into the comprehensive UltiMaker ecosystem. Get up to 4x productivity, hundreds of materials, and powerful tools like Cura Cloud and UltiMaker Digital Factory, all within easier reach.

Discover how professional 3D printing can unlock new efficiencies in your production line, one part at a time.