Azoth has built a new business helping manufacturing customers have machine parts right on time, while saving thousands of dollars.

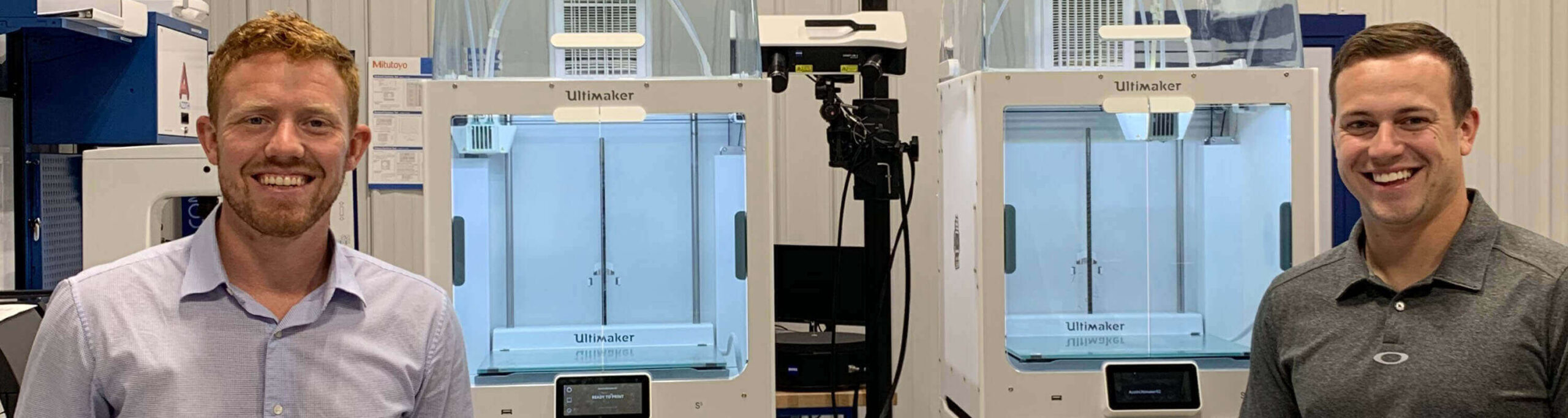

When engineers get enthusiastic on the topic of additive manufacturing, it can be compelling. Indeed, in the presence of Cody Cochran, Azoth’s general manager, and Ronnie Sherrer, polymers engineering lead at Azoth, you can’t be anything but a fan. Their expertise and energetic approach have been successful in consistently delivering new value propositions to their manufacturing customers through the intelligent application of additive manufacturing and 3D data for end-use parts.

Additive manufacturing and materials have recently evolved to the point where many end-use parts can be produced tool-free and at a lower cost than traditional methods. According to Cochran, it is all about identifying parts in their customers’ inventories that meet the specifications and having a clear business case. Then they are evolved into a digital inventory for immediate, on-demand part production.

“Not all parts are ideal for additive,” said Cochran. “We sort through and find where the complexities are in the supply chain, the overload of inventory, where parts often fail, and build a business case for each one.”

Azoth was formed by the EWIE Group of Companies (EGC) to bring the advantages of additive manufacturing to its customer base. EGC focuses on fulfilling the indirect manufacturing needs of its Fortune 500 customer base across 12 countries, with customers such as John Deere, GM, and Ford. Azoth also focuses on those indirect needs by applying additive manufacturing to machine parts.

Azoth have achieved significant part cost reductions for customers, reduced inventory, and streamlined parts supply

The Azoth Approach

As customer engagement begins, the team at Azoth takes a methodical approach by working through their inventories and initially identifying machine parts that are overstocked as a result of minimum order quantities or that are often out of stock because of lengthy production lead times of five to 10 weeks—or longer. The team then goes on to identify parts that have a high failure rate or that need some re-engineering for greater efficiency. All of these parts are wasting their customers’ money, wasting time, and causing unnecessary complexity in the supply chain.

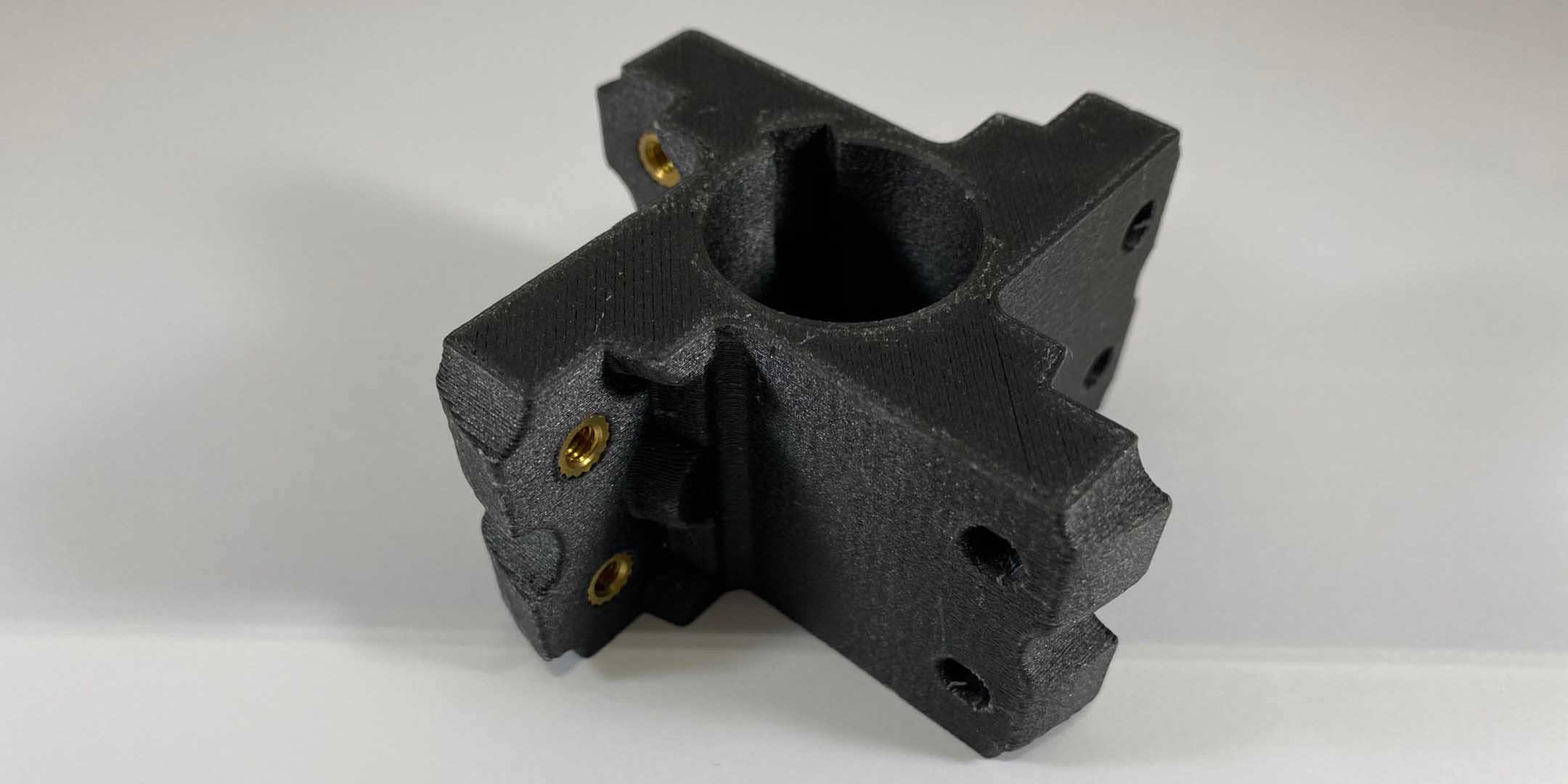

The Azoth team is equipped with 3D scanners and software so that parts without CAD data can be reverse-engineered and then re-engineered, if necessary, to improve mean time between failure (MTBF). Material analysis is applied, as well as an understanding of the tolerances in play. And asa part is validated, an analysis of cost—including post-processing, material, build times, and part size—is delivered.

Selecting the right 3D printer and materials is also part of this equation. Azoth uses both metal and plastic additive manufacturing and is particularly reliant on its Ultimaker 3D printers in this process. The Ultimaker systems use fused filament fabrication (FFF) technology and are compact enough to fit on a desktop while delivering generous build sizes: The S3 offers a build size of up to 230 x 190 x 200 mm and the S5 can build up to 330 x 240 x 300 mm—both with dual material extrusion and layer thicknesses as small as 20 microns.

“The materials and the printers from Ultimaker are key in this process,” said Cochran. “The low cost of operation, the high-quality materials, have made our success possible—providing significant cost reductions for our customers.”

The team also looks at metal parts to see if they can be produced more efficiently in plastic while maintaining tolerances and performance.

“The Ultimaker materials are less expensive and often outperform traditional plastics, and even some metals,” said Cochran. “With some gripper finger parts that were originally machined from metal, we took the cost from $350 down to $75 per part by re-engineering them for plastic additive production. And they maintained performance.”

Aluminum gripper fingers converted to 3D printed polymer gripper fingers, designed with added hardened dowel pins

The types of parts that the Azoth team analyzes include jigs and fixtures, gripper fingers, blow-off nozzles, gage handles, and more. They look for parts that will benefit from being produced additively, and with no tooling, tool setup, or minimum order quantities, amazing time and cost savings can be made.

“The average person wouldn’t find these parts sexy in any way,” said Cochran, “but these are the workhorse parts that enable production to continue. We work to eliminate machine downtime on our customers’ shop floors, reduce complexity, reduce cost, and shrink physical inventory. And we have been successful at it!”

Azoth increased performance by designing a nozzle that hits the part exactly where it should – previously this was unable to be manufactured

Take One, Make One

Once the customer’s digital inventory is in play, Azoth uses a model it calls “Take One, Make One.” This is a direct form of on-demand production where as soon as a replacement part is taken, a new part is made. Azoth operates this through synchronization with parts vending machines and ERP/MRP systems that send an order to Azoth’s competency center. The new part is typically built and shipped within 24 hours.

"The vending machine implementation can generate instant work orders,” said Sheerer. “This means that the customer maintains a limited inventory driven by actual usage and not based on random requirements, such as minimum order requirements. This saves money and increases efficiency for the manufacturer.”

Dynamism, a provider of 3D printing solutions, materials, and consulting expertise located in Chicago, Illinois, was a key collaborator in the company’s TOMO initiative. The Azoth team was introduced to the Ultimaker platforms by Dynamism, and both teams maintain a strategic relationship to push the boundaries of 3D printing.

“The continual support, expertise, and creativity from the Dynamism team allows us to meet the needs of our customers,” said Cochran. “Their help means we can always offer the best solutions, materials, and outcomes.”

This automotive fixture is 3D printed with magnet inserts for self-locating the component

In the event of running out of inventory of a steel injector pin, a polymer replacement can be 3D printed in two days

The results

Each part produced by Azoth is delivered with a proven business case for the customers. Depending on the part, the business case can be quite different.

“Our approach disrupts the status quo in a positive way for our customers,” said Sheerer. “When we transitioned a simple wear pad part to additive with Ultimaker, it resulted in $30,000 in cost savings for the customer. That is what we call a business case.”

The ability to rapid prototype parts is also a part of the work done by the Azoth team. For some prototype cutter parts, the customer would typically have them CNC machined in steel, which took 12-14 weeks. The Azoth team had plastic prototypes that could be used for a direct, accurate fit and checked within one day. Azoth’s results speak for themselves. They are regularly achieving cost reductions of 50-90%.

The lead time for this prototype cutter part is one day with 3D printing, compared to 12-14 weeks with CNC machining

“With one gripper finger part, we produce about 30 a month at about half the cost of the traditionally manufactured part,” said Cochran. “We tested the new part with SLS nylon, SLA-based resin, but ended up using the PA 4035 on the Ultimakers. It replaced Delrin, and that’s a tough, workhorse material in our world.”

The Azoth team is also able to produce emergency parts to help reduce machine downtime. One example was of a tool steel injector pin that ran out in inventory. The team had a polymer replacement pin in 48 hours, whereas the 3D metal replacement took a week.

Azoth are able to produce 30 of these gripper fingers for end of arm tooling each month with Ultimaker 3D printers

With the tools and expertise, the Azoth team is also able to re-engineer parts for better performance. Complex blow-off nozzles with designs that accurately target the air flow are great examples—and are simple to produce with additive manufacturing.

The Azoth team has proven to itself and its customers that additive has a valuable and important place in the manufacturing supply chain, and both Cochran and Sherrer are keen to continue to lead, innovate, and help customers be more successful.

“Daily, we are changing mindsets within our customers as we deliver valid business cases on their parts inventory using additive manufacturing,” said Cochran. “With Ultimaker 3D printers and materials, the cost is right—they offer easily scalable production and a reliability that we couldn’t have anticipated.”