Years ago, when I first began teaching at Riverside, I was asked to teach an engineering design course to 14-17-year-olds. As the only teacher in our program with a propensity for designing and creating, I was the obvious choice to send for training. I set out knowing I would need to learn how to utilize and implement a piece of CAD software called Inventor Pro. A day or two into the training and I was introduced to the Puzzle Cube project; a short assignment that reinforces the design process and introduces students to Inventor’s basic tools and usage---certainly not intended as a final project for the course.

Wowed by the potential of this assignment resulting in a toy to play with and the creation of a package to keep it in, I was determined to find ways of enhancing this mid-curriculum project. Most assignments in our engineering curricula are open source by design---meaning anything and everything about them is intended to be altered and you are encouraged to share these changes. During the first couple years of assigning this project, I treated it much like my experience at the training. Students followed the activity and project sheets exactly, reporting their likes and dislikes, and were assessed with rubrics. Because of this, students didn't seem to want to dig deeper into the design process---they just followed the directions---and what simple directions they were. So simple, in fact, that students had difficulty transitioning from one task to the next. They would ask “How?” and “Why?” so much it made sense to let them determine their own answers.

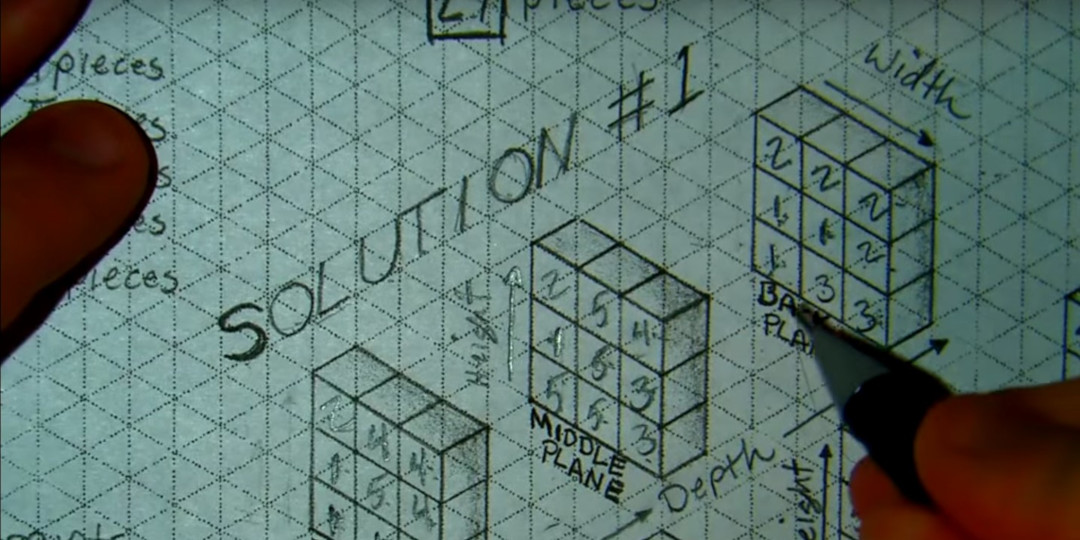

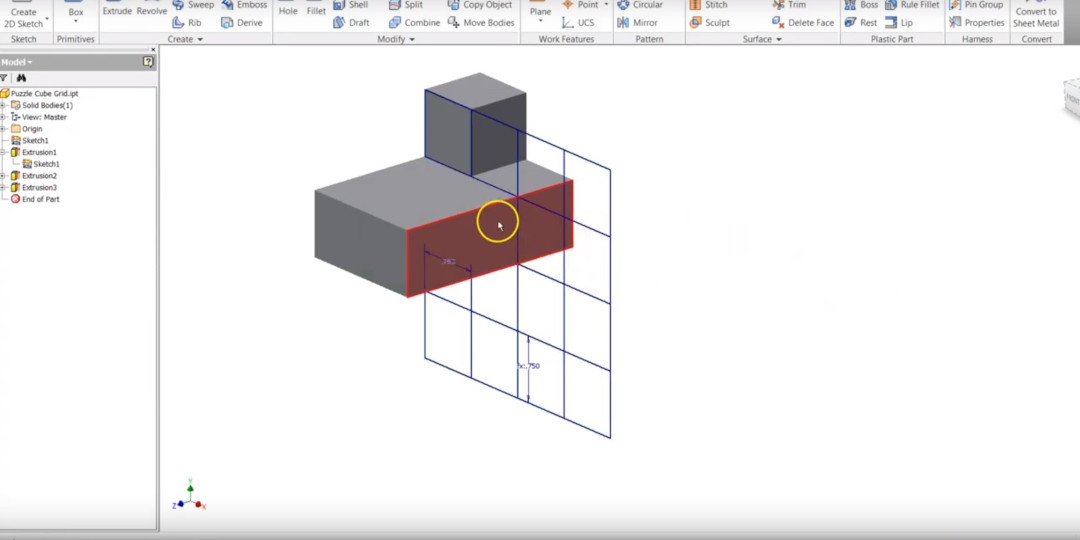

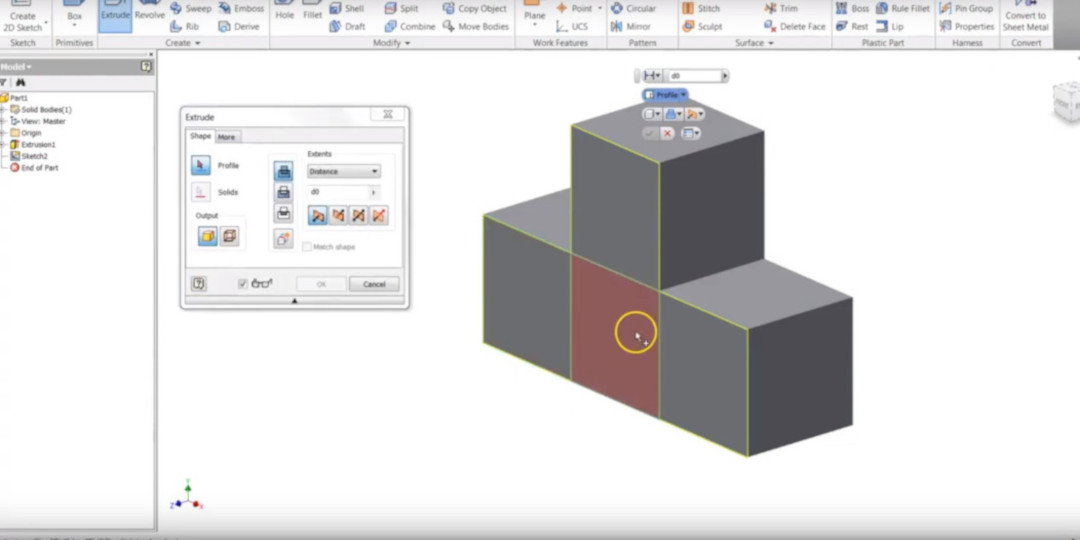

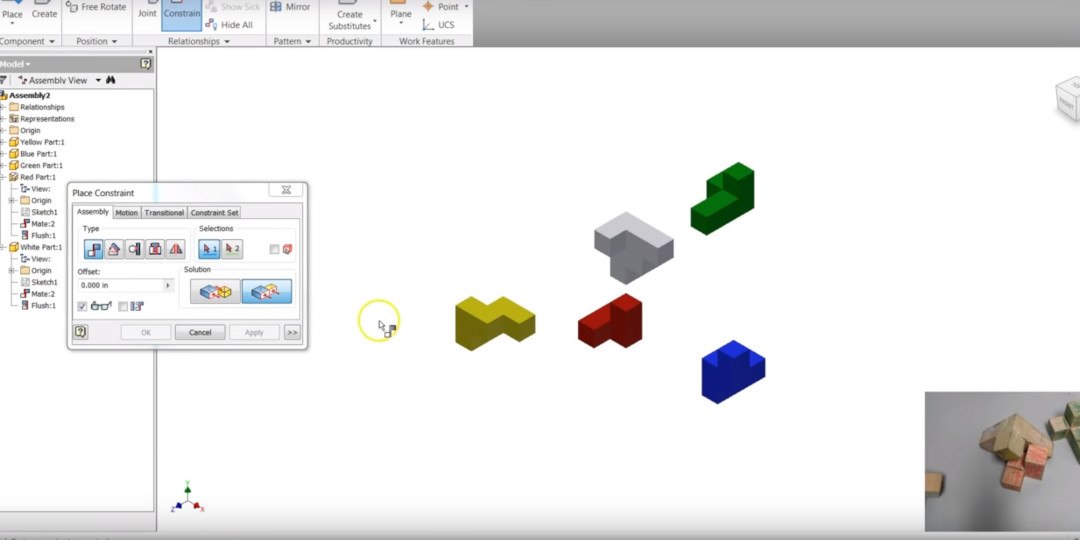

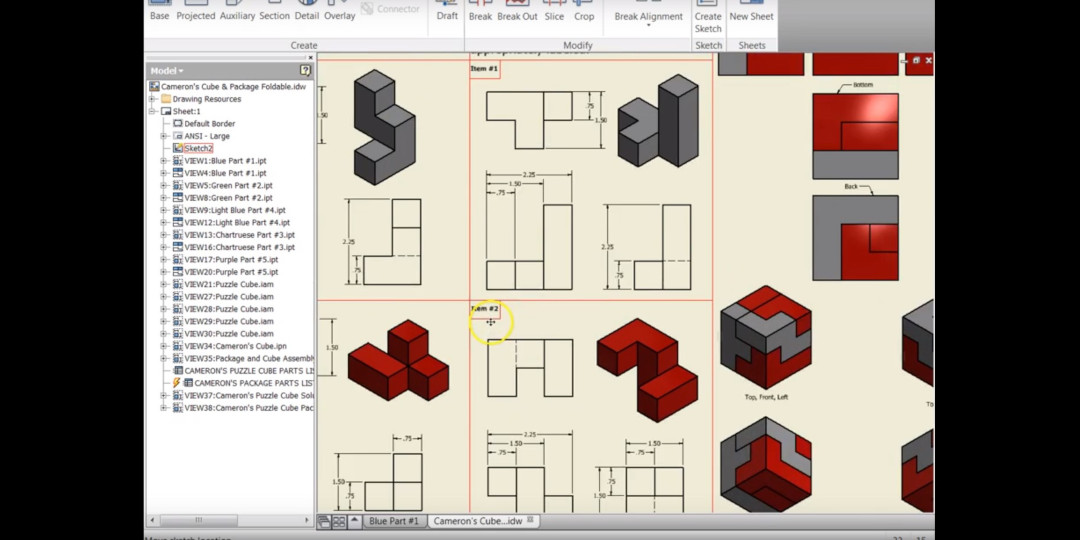

The project originally began by having students sketch a variety of parts that satisfied a set of criteria and a few constraints. For example, parts had to be a particular size to fit within a puzzle. The puzzle would later be designed by fitting parts together and discovering which parts were needed in the end to complete the 3 x 3 x 3 piece puzzle. The curriculum had many different activities for the students to reference and complete. But there was an insistence that students work individually and share their designs with classmates, instead of encouraging teamwork and reinforcing collaboration. Because the project became monotonous for me as an educator, and because students took it upon themselves to suggest (and request) changes in the project guidelines, I decided to upend this assignment and recreate it keeping in mind 3D printing technology and a bit of role-playing. I also decided to ditch the activity and projects sheets along with all rubrics. I created a few helpful guides and a persona whom I would role play.

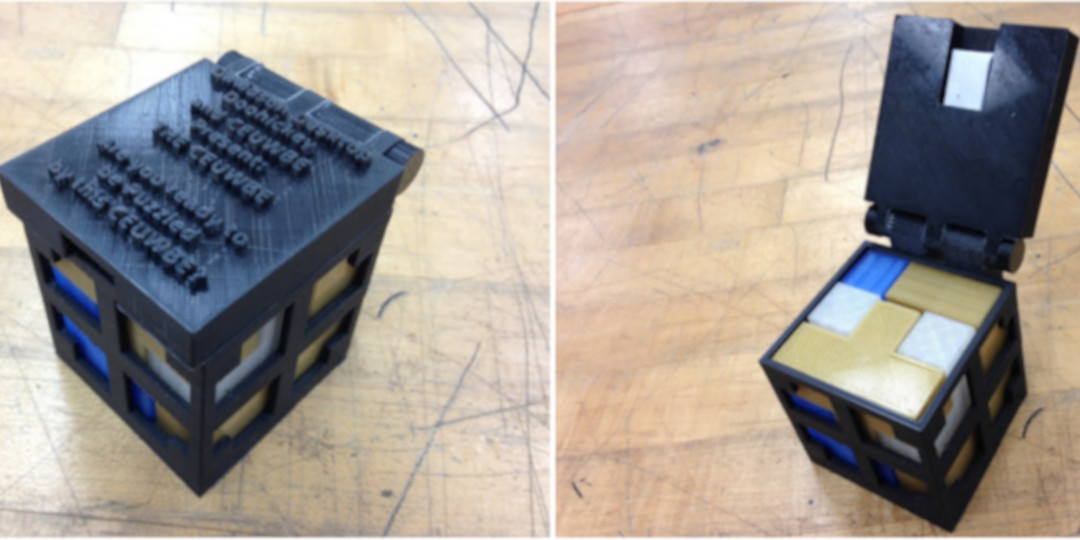

This changed the game completely. Students began enjoying the project again. They loved the idea that they were in charge of their own depth of learning. They selected their own teams. They developed contracts for their teams, and most importantly, held themselves to the team norms in their contract. The persona I developed, owner and operator of Davidson Desktop Doohickeys, became their boss; the person they could report to when problems arose and impress when designs were finalized. Instead of working individually, occasionally sharing their thoughts with classmates, the assignment became a team final project. The students, or employees as I would now refer to them, were encouraged to raise the bar each semester making the project take on new meaning, new constraints, and more challenges than ever before. They became deeply involved in the development of their curriculum. They were not responsible for creating the project, they were inherently doing it because they felt the need to make it “better” for the next group of employees.

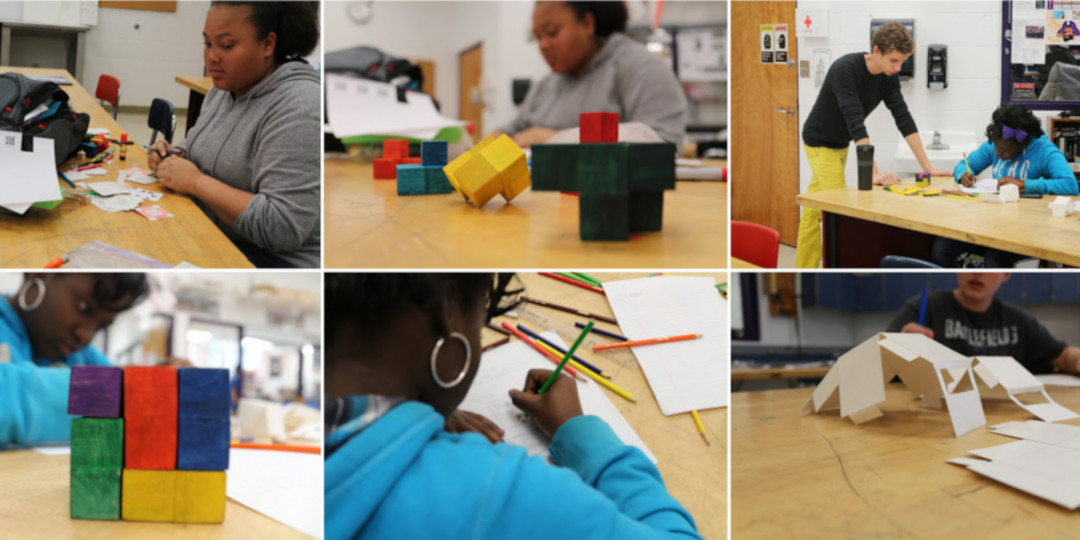

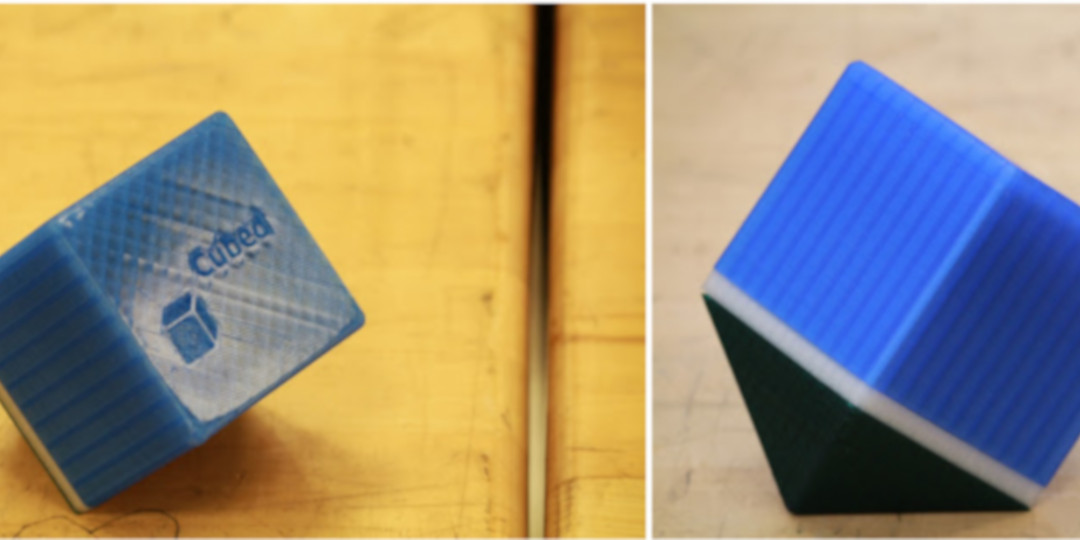

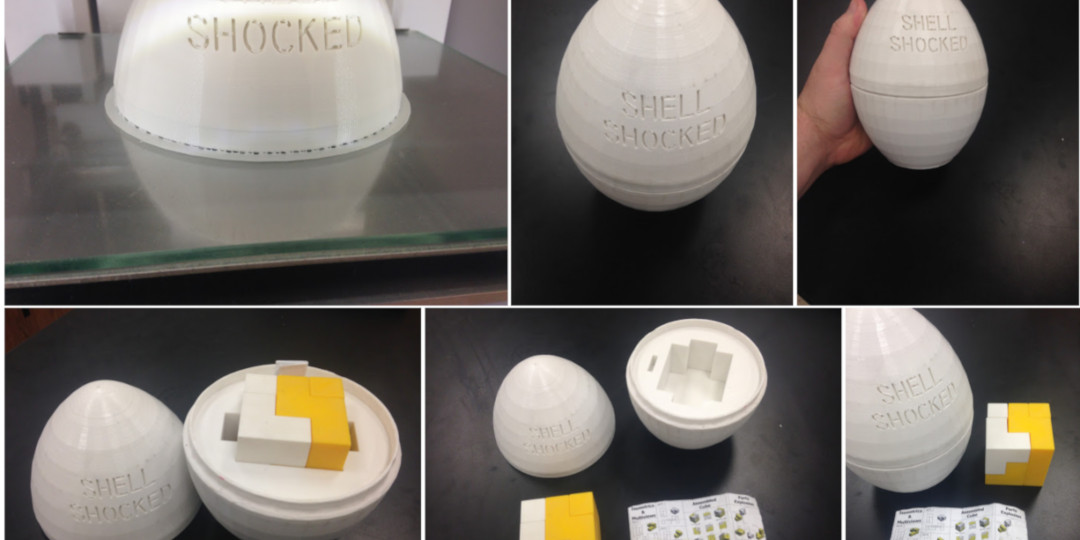

While writing this blog, I think back to nearly a decade ago when my students created wooden block puzzle cube parts. Gluing them together, they had to tirelessly sand them smooth. The parts were colored with permanent markers and sometimes poorly painted. Packages were made from card stock; net patterns held together with tape and rubber cement. Some were better than others, and over the years students created some awesome packages and had some great ideas. But this meant the project began changing as new potentials were realized and eventually with the implementation of our Ultimaker 2’s, 2+’s, and now our Ultimaker 3 Extended, my employees are creating extraordinary designs for their cube parts. They have moved on to extremely complex packages and can print them with precision they were never able to achieve using wooden blocks and cardstock.

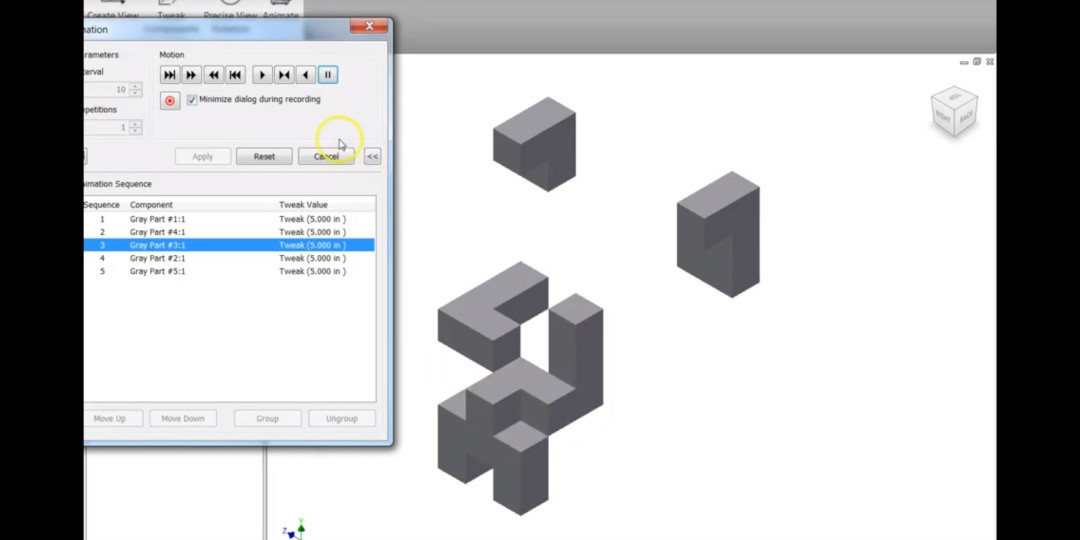

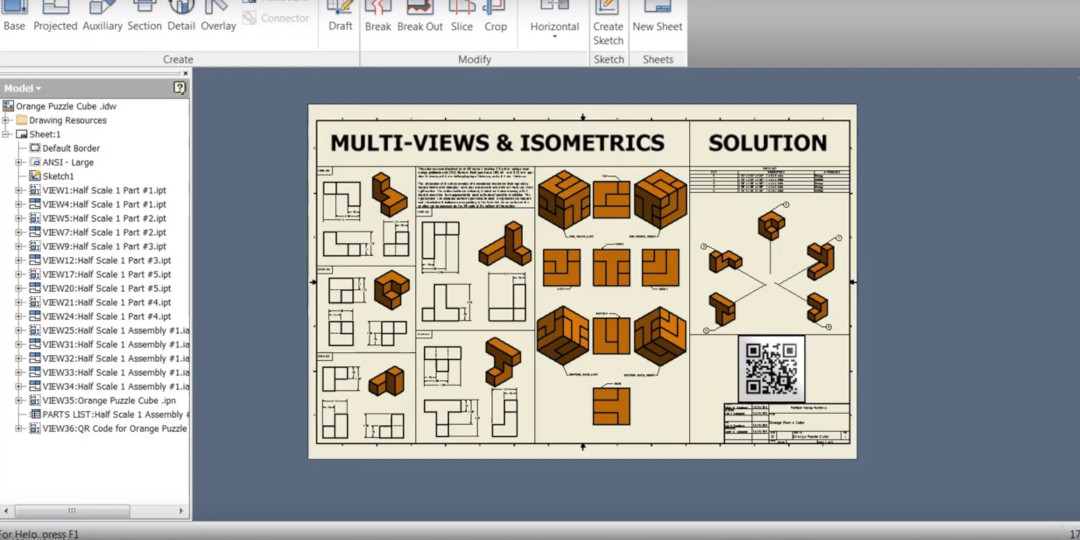

My employees still start with the end in mind, but now they work in teams from nearly the start of the semester. Using a 3-plane explosion solution sheet they create their own prototypes. They now work together to utilize a decision matrix to determine the best prototype, color choice, and other decisions they need to make as a team. Employees still use Inventor Pro to develop 3D models, assemblies, videos, and drawing sheets that are used to explain their completed product and demonstrate a working solution. Their skills are enhanced further when they create a package that matches their overarching theme and a portfolio that compiles their process and work.