Have you ever discovered a great new engineering filament only to find that you need to configure hundreds of settings in your slicing software to use it? Ultimaker has a solution.

Our open filament system enables you to load and print third-party filament of your choice, but achieving high-quality results also depends on a range of software settings – especially when using materials with advanced engineering properties. It’s possible to adjust settings individually with some trial-and-error, but this is a time-consuming, error-prone process that will cut into your bottom line.

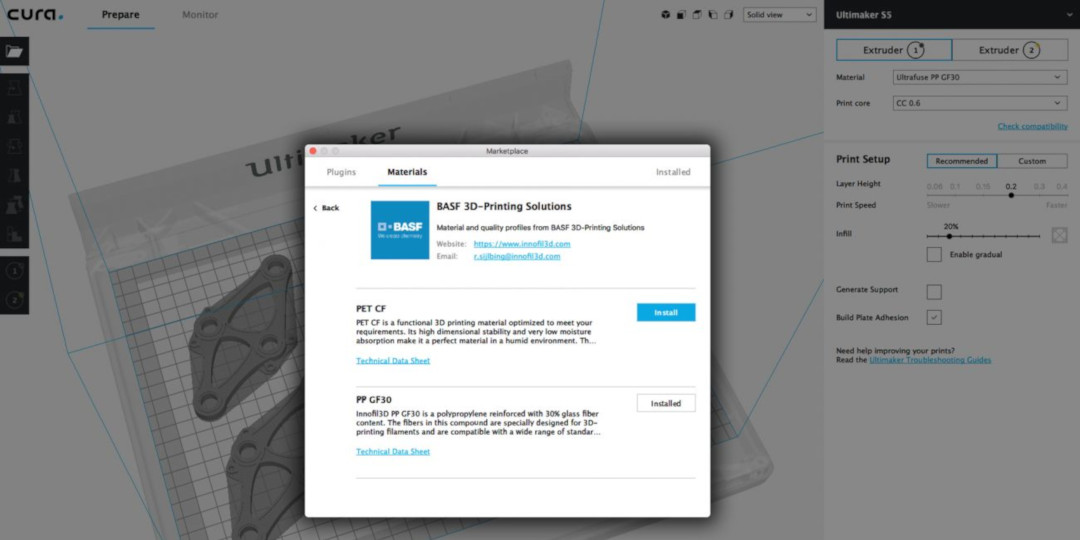

To tackle this challenge, Ultimaker has formed alliances with leading material manufacturers, such as BASF, DuPont, DSM, Owens Corning, and Clariant, who have developed print profiles for their own 3D printing materials that are optimized for Ultimaker software and hardware, including the Ultimaker S5 and print core CC Red 0.6. These profiles are now available in Ultimaker Cura via the Marketplace, and enable you to easily prepare prints and achieve reliable results for carbon fiber, flame retardant, ESD-safe, and many more advanced 3D printing materials.

But how does each profile end up in the Marketplace?

The Marketplace in Ultimaker Cura 3.6

Reducing development time

Print profiles in Ultimaker Cura consist of a range of slicing parameters. We enable members of our alliance program to develop profiles using specialized software tools that work with our software and guide the process. Slicing parameters are adjusted by the supplier, and tested against a series of sample models with complex geometries for FFF 3D printing. Using this software, suppliers are able to verify if the material will have good overhang quality, build plate adhesion, compatibility with water-soluble or Breakaway support material, and other important factors to ensure a reliable 3D printing process.

The advantage of a guided development process is that profiles that would usually take six months to develop from scratch for the Ultimaker S5 can now be achieved in a few weeks.

When a profile is sufficiently tested and validated by the supplier, it is submitted to Ultimaker Cura’s Marketplace via our contributor portal. Each supplier is in full control of the information that is published with the print profile, and is able to include relevant supplementary information, such as data sheets, printing guidelines, and certifications.

BASF materials in the Marketplace

Available to millions of 3D printing professionals all over the world

Contributing profiles to the Marketplace is an extremely effective way to broadcast materials to Ultimaker Cura’s user base, which includes thousands of engineers, designers, architects, and other 3D printing professionals worldwide.

To date, over 60 different material manufacturers have voiced their interest in our alliance program, and as time goes on, the Marketplace will be further enriched with more profiles for reliable prints.