We decided to dig deeper into the manufacturing industry as a whole to answer the question: What exactly is a manufacturing minute worth?

What’s a manufacturing minute worth?

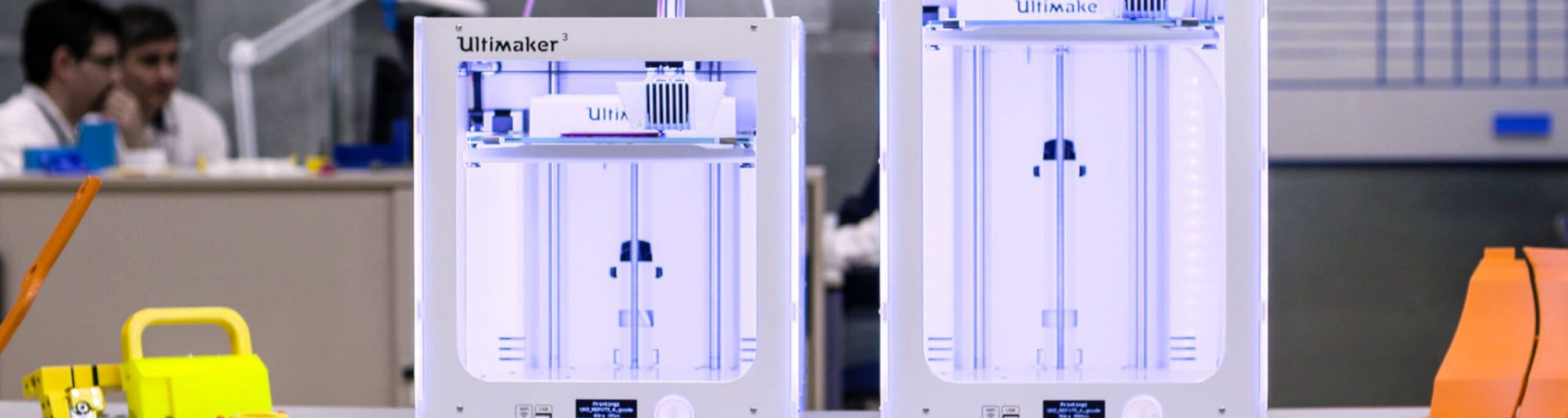

Almost every major automotive brand, including Volkswagen Autoeuropa, has documented the benefits that 3D printing has brought to their design and production process, noting significant reductions in both time and cost. To demonstrate the potential financial impact of these efficiencies brought on by 3D printing, Ultimaker recently explored what a minute is worth in the automotive industry. What we found: the cost of automotive manufacturing in the United States is $460,706 per minute or $1,110,663,840 per week.

Replicating the same formula and evaluating similar publicly available statistics, Ultimaker found that the cost of US manufacturing is $4,258,341 per minute, while the revenue is $4,280,821. This means that the margin for profitability per minute is just $22,480. Such tight margins suggest that even the slightest improvements in efficiency – like those brought on by 3D printing – can introduce time and cost savings that have a major influence on a company’s bottom line.

Many major manufacturers are already reaping the benefits of 3D printing. For example, Jabil, one of the largest manufacturing service providers in the world, has implemented 3D printers into the workflow at their Auburn Hills facility, cutting production time by 80% and reducing the cost of tooling by 30%.

Jabil’s engineers understood early on that having to wait three weeks for a machine shop to produce a tool – up to two months for complicated parts – was significantly reducing their ability to create custom products in a timely manner. In order to better serve their healthcare and industrial customers, it was essential that they found a way to speed up production time while also cutting costs.

The full methodology and numbers are below. As professional 3D printers become mainstays within the industry, it will be interesting to see if these profit margins increase due to cost and time savings, and greater efficiency overall.

The numbers, including the following, are based on these public data sets from the Bureau of Labor Statistics (BLS), which report the number of people employed in the U.S. manufacturing industry, the number of workers in certain manufacturing roles, and average salaries for each role. Additionally, manufacturing industry economic data was brought into the calculations.

Manufacturing minute costs (employees/salaries rolled up together)

Per week – $43,042,002,652

Per day – $6,132,011,337

Per hour – $255,500,472

Per minute – $4,258,341

Manufacturing revenue

Per week – $43,269,230,769

Per day – $6,164,383,562

Per hour – $256,849,315

Per minute – $4,280,822

Revenue margins

Per week – $227,228,117

Per day – $32,372,225

Per hour – $1,348,843

Per minute – $22,480

Are you surprised by the worth of a manufacturing minute? What do you think about 3D printing’s impact on the industry?

Find out more about how 3D printing can save time and costs for your business: