One neat application of 3D printing is fabricating tools and parts in remote locations, like on Navy vessels at sea or on the Space Station. It costs thousands of dollars to put just one pound of anything into space, and yet astronauts need backup tools and spare parts. What if instead of sending all those extra tools and parts (many of which never get used), you just had a printer with files for parts? Then you could print them on-demand and save weight and space. What’s more, custom parts can be designed on Earth and then printed in space. Commander Barry Wilmore printed the first ever tool in space, a socket wrench made available by NASA. This wrench actually has a ratchet mechanism built-in, so it ratchets right off the printer.

Wrench Engineering

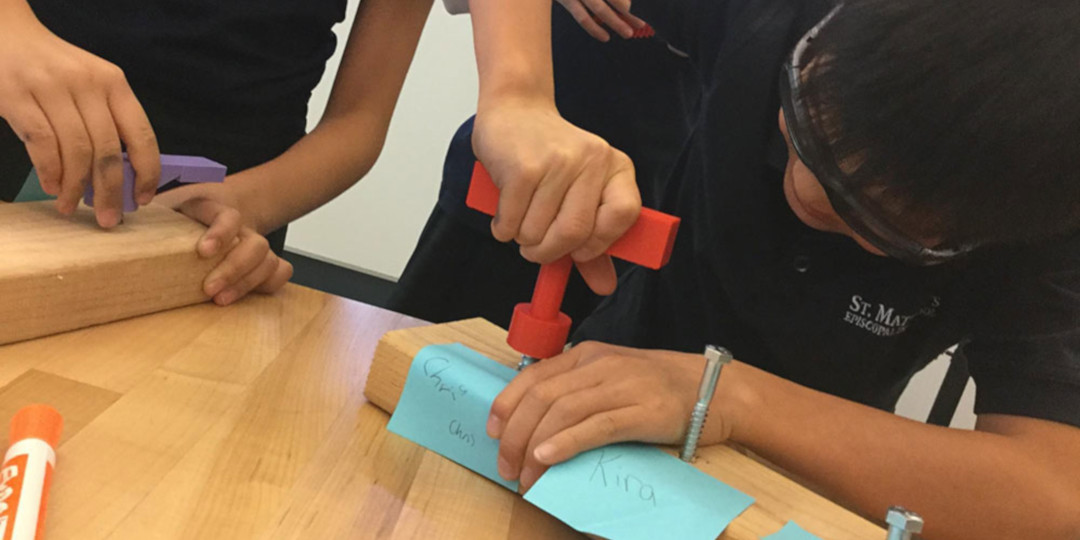

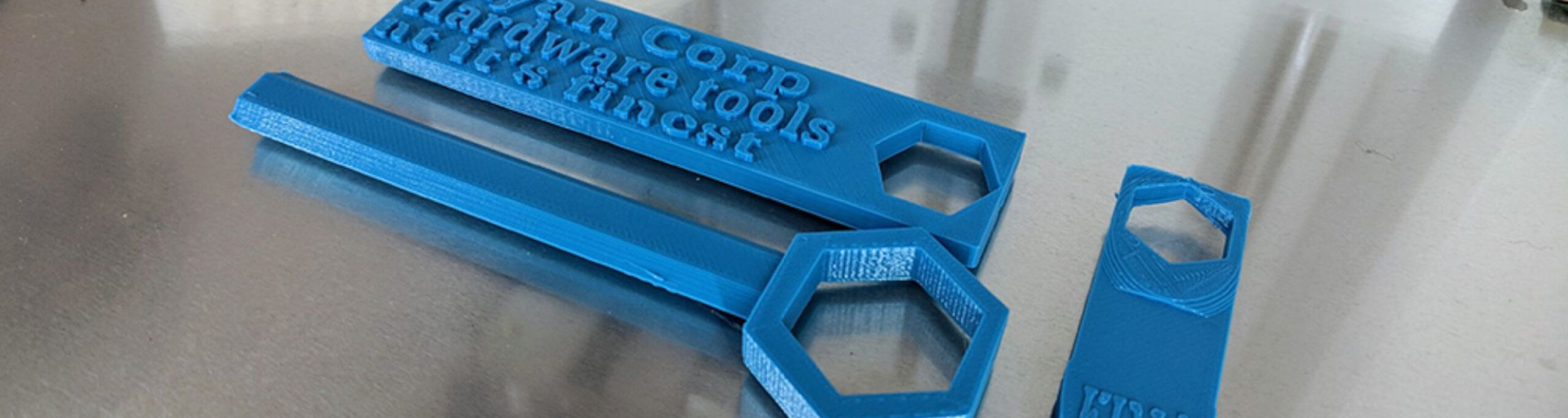

Inspired by NASA printed in space wrench, Pioneer Rob Morrill gave his fifth graders a design challenge to design their own real-world tool.

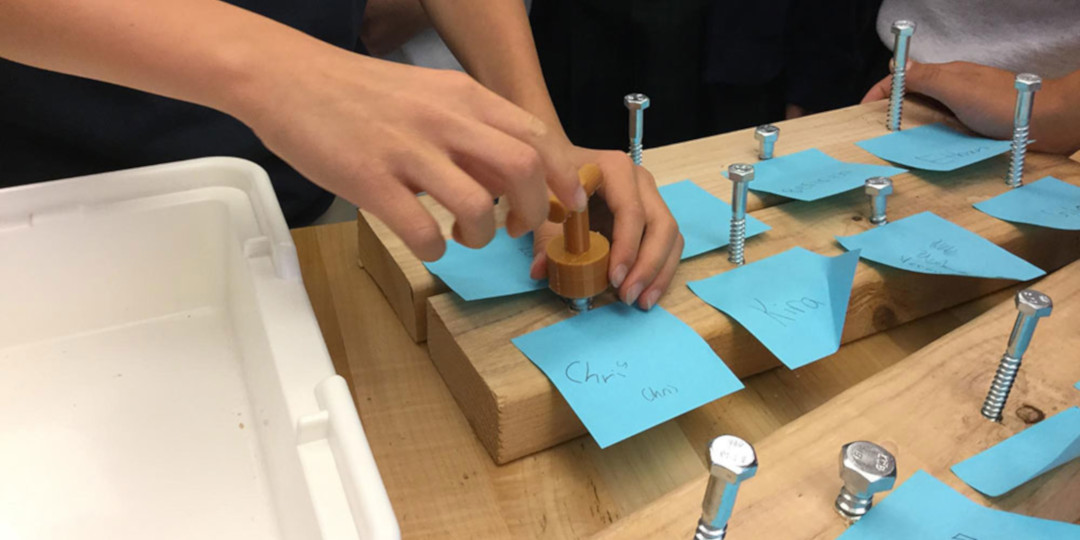

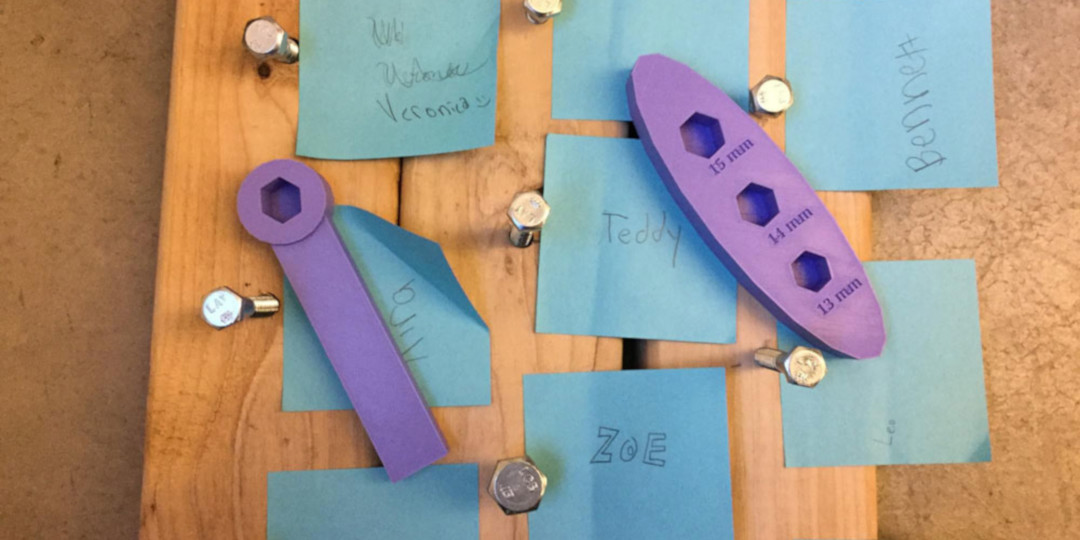

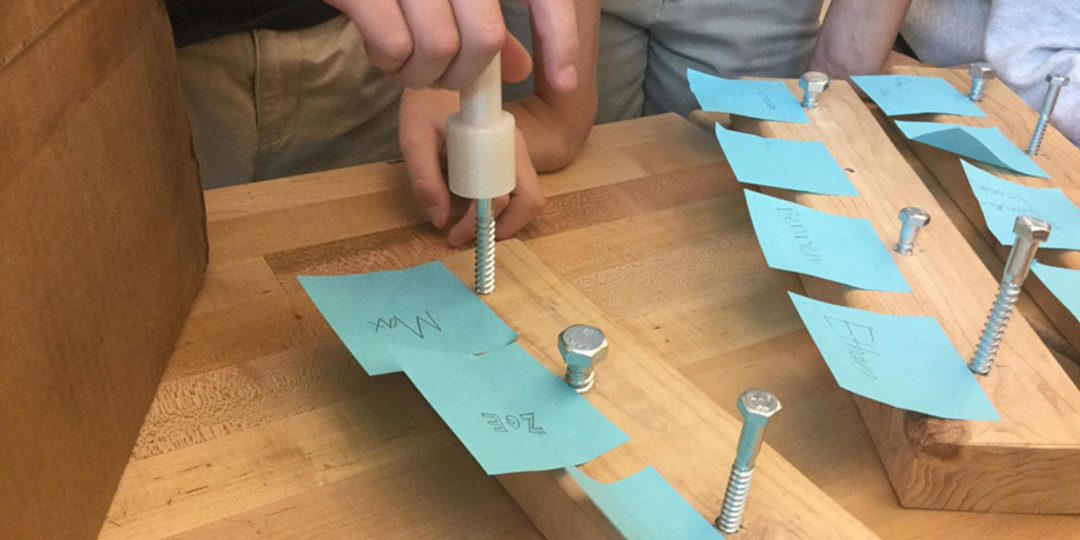

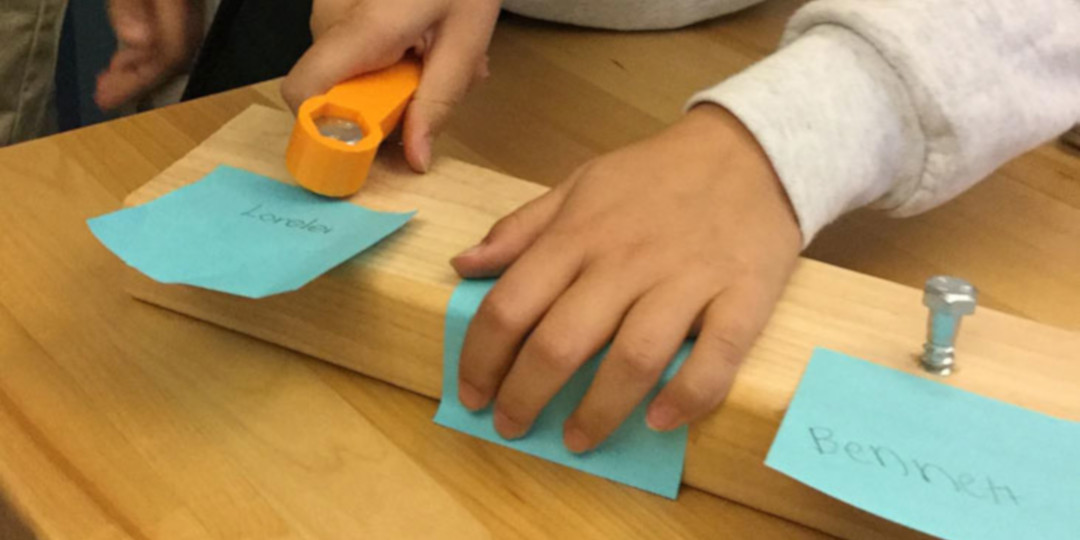

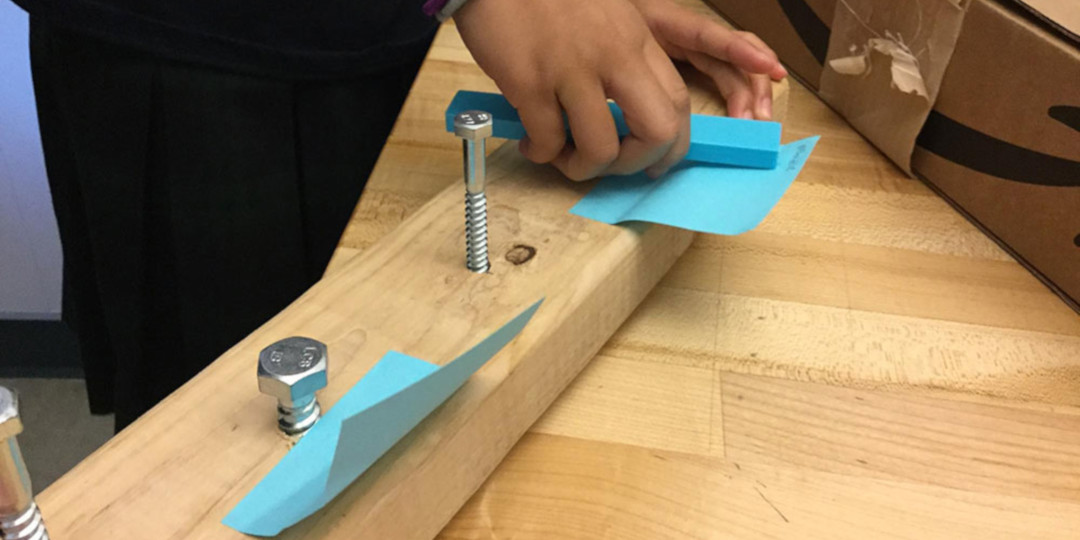

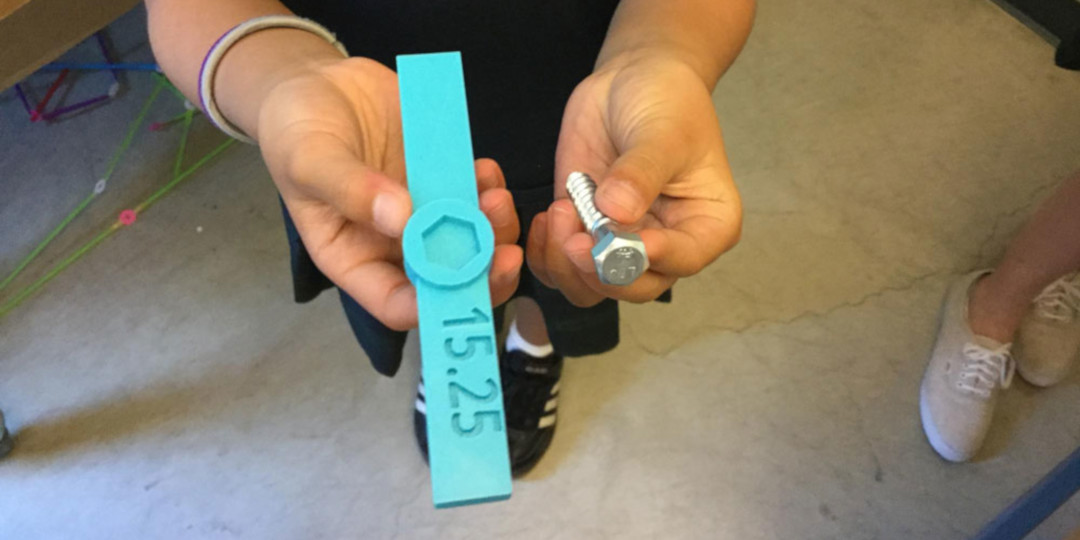

I developed a design challenge for my fifth graders that asks them to design a real-world tool. I take several lengths of 2x4 wood, drill pilot holes, then screw lag screws of various sizes into the wood. Every student is assigned a screw, and they must engineer a custom wrench to get it out of the wood. We learn to use calipers to measure the distance between the flat sections of the screw heads.

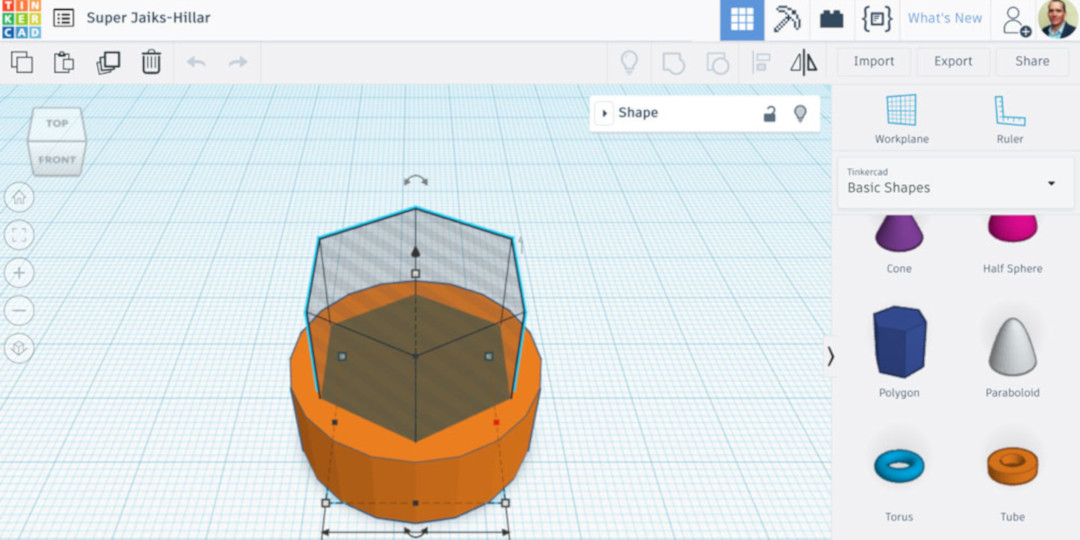

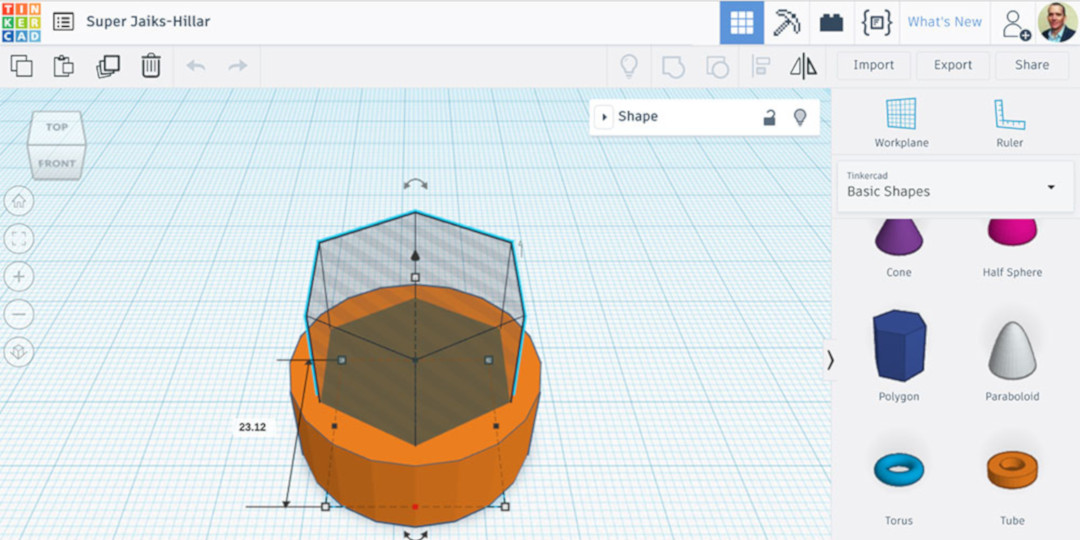

In Tinkercad, students use the polygon shape and turn it into a hole. If you use Tinkercad, be sure to set your snap grid to .1 mm, hold shift as you enlarge so the entire shape scales up or down, and change the dimension of the flat sides of the polygon, not the pointed dimension, which is larger.

Resize your polygon with the flat sides:

Don’t resize your polygon with the pointed dimension:

Students come up with various designs for their wrenches. Sometimes the polygon hole ends up too snug or loose, sometimes the handle gives little or no leverage, sometimes the handles are functional but cut into the palm, and sometimes other edifying failures arise. When wrenches don’t work, students redesign and iterate. At the end of the unit, we reflect on various aspects of the technology itself, the design and iteration process, as well as the larger thinking skills we engaged in.