The seamless, powerful upgrade that your production workflows demand.

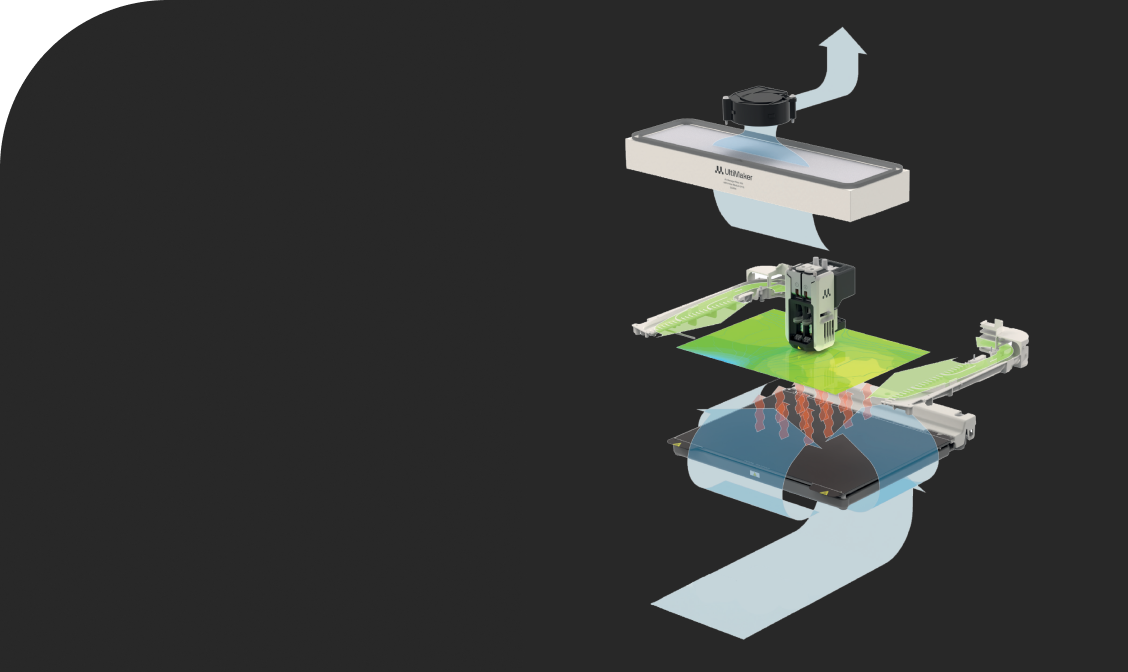

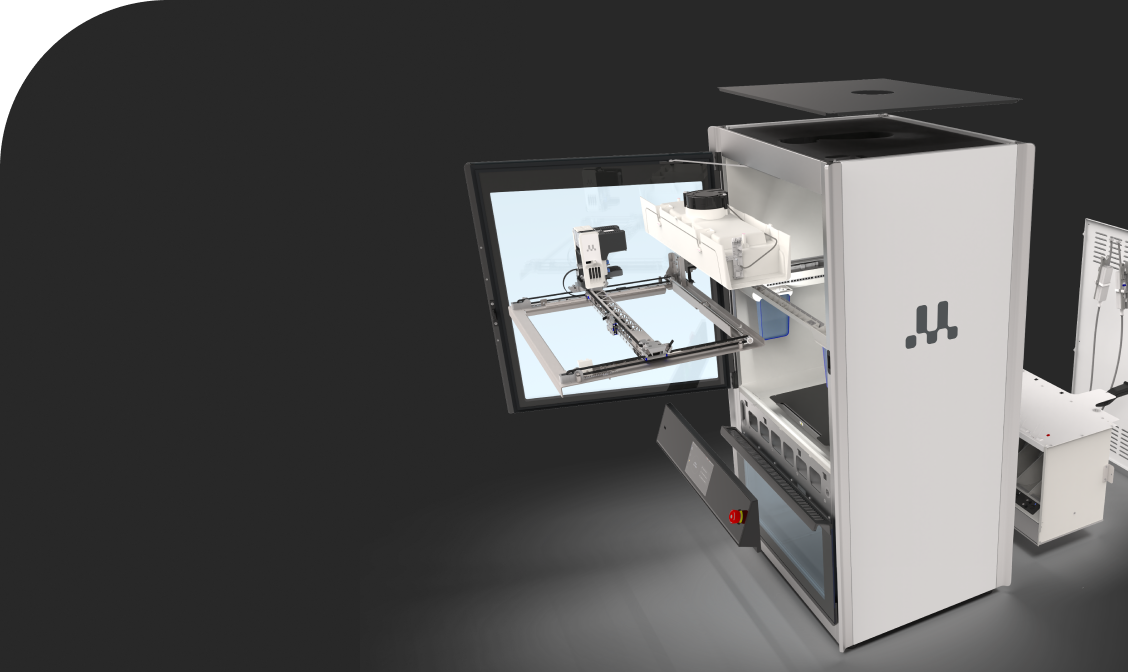

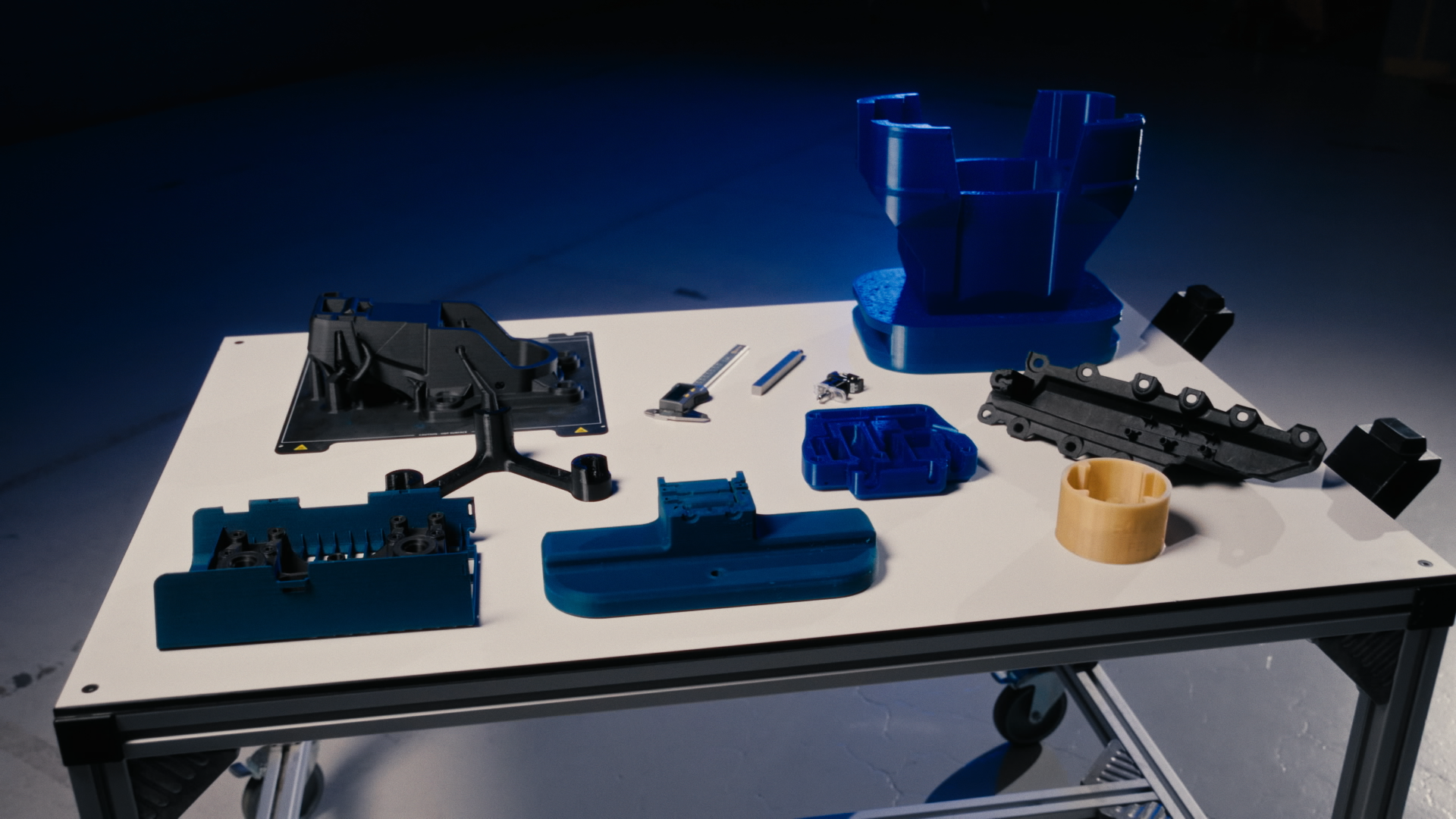

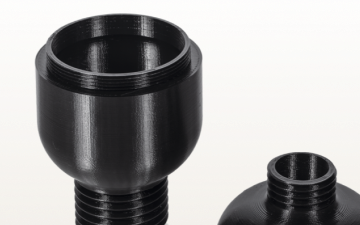

Factor 4 elevates manufacturing with its triple-insulated build chamber and direct dual extrusion. The automated material handling system maintains filament quality. And the robust, temperature-controlled design ensures consistent production output also on complex and challenging designs.

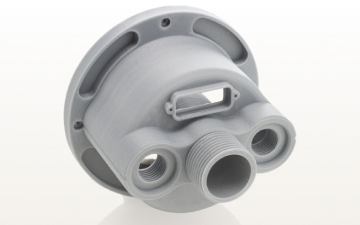

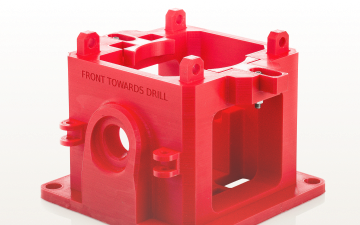

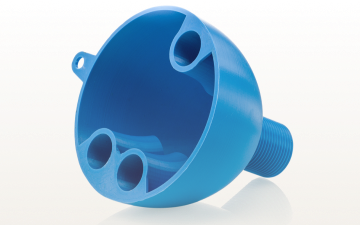

Heavy duty, heavy weight

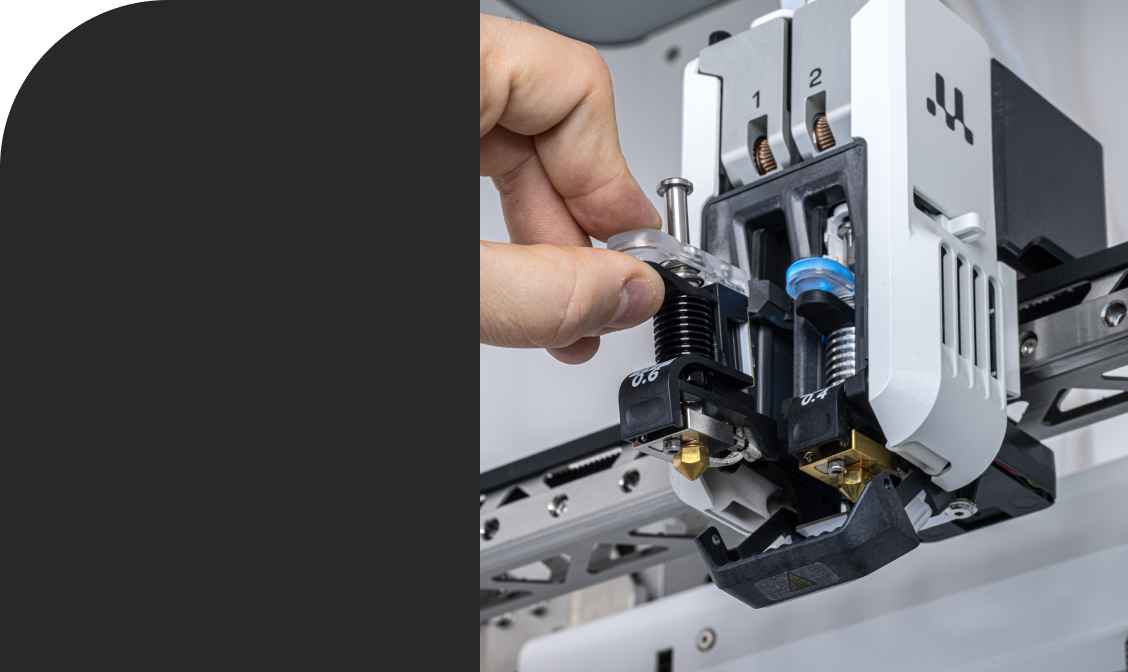

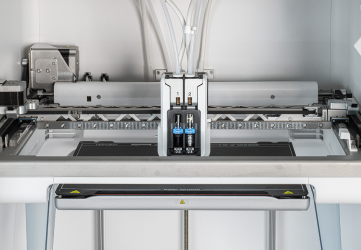

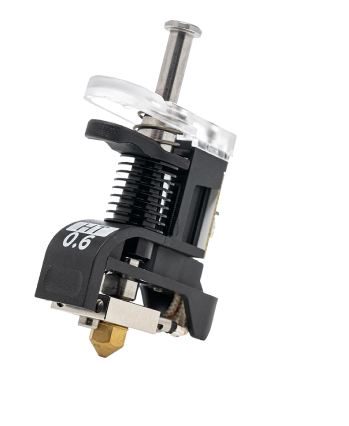

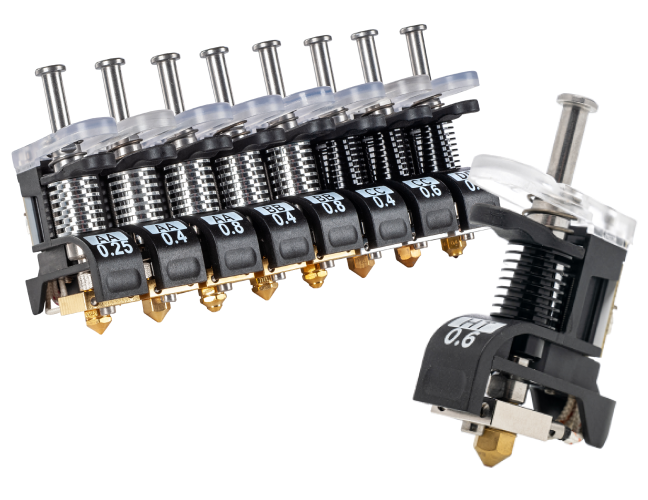

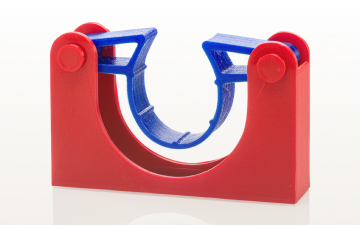

Direct

Dual

Extrusion

effective dual 3D printing