Environmental factors affecting 3D print accuracy

In addition to software settings, environmental factors play a crucial role in achieving optimal print accuracy. The environment in which industrial 3D printing takes place significantly influences 3D print accuracy and overall quality. These factors work in conjunction with the software settings and calibration techniques discussed earlier to ensure the best possible print results.

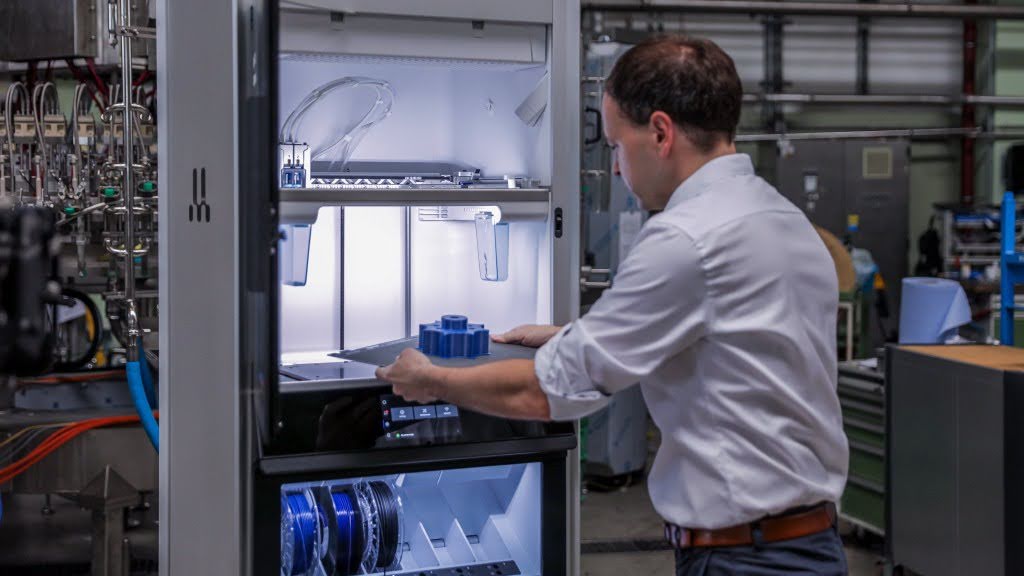

Maintaining a stable ambient temperature is essential for achieving high accuracy in manufacturing settings. Consistent room temperature helps prevent warping and layer separation, while enclosed printing chambers help maintain optimal temperatures for materials sensitive to temperature fluctuations. The room's dimensional volume and air exchange rate are key factors that affect indoor air quality when 3D printing, which in turn can impact print accuracy and overall quality.

Humidity is a critical factor that affects both the printing process and material properties in industrial applications. High humidity can cause moisture absorption in hygroscopic filaments, leading to poor surface finish and weak layer adhesion. Maintaining low humidity (30-50%) in the printing area is ideal for most materials used in manufacturing. Proper air circulation impacts print cooling and overall accuracy in industrial settings. Adequate airflow helps cool layers quickly, improving surface quality, while controlled air circulation is particularly important for materials sensitive to cooling rates.

Minimizing vibrations is crucial for maintaining high accuracy in manufacturing environments. External vibrations can cause shifts in print layers, reducing dimensional accuracy. Placing printers on stable surfaces or using vibration-dampening systems can improve print quality in industrial settings. A clean printing environment contributes to better accuracy in manufacturing. Regular cleaning of printers and surrounding areas, along with the use of air filtration systems, helps maintain consistent print quality in industrial 3D printing applications.

Quality control methods for industrial 3D printing

Quality control in industrial 3D printing requires systematic measurement and verification techniques to ensure consistent part accuracy and performance.

Implementing dimensional verification using precision measurement tools such as coordinate measuring machines (CMMs), laser scanners, or digital calipers allows manufacturers to compare printed parts against CAD specifications with micron-level precision.

For critical applications, non-destructive testing methods including CT scanning and ultrasonic inspection can reveal internal defects or voids that might compromise structural integrity.

Many manufacturing facilities are now implementing in-process monitoring systems with high-resolution cameras and sensors that detect anomalies during printing, enabling real-time adjustments before defects propagate through the part.

Establishing statistical process control (SPC) protocols helps identify trends and variations across production runs, while maintaining detailed quality documentation for each print parameter creates a valuable knowledge base for continuous improvement.

For industries with stringent requirements like aerospace or medical device manufacturing, implementing standardized testing protocols based on ASTM or ISO standards provides verifiable evidence of part quality and consistency.

Troubleshooting FAQ: Common 3D print quality issues

Building on our comprehensive exploration of factors affecting 3D print quality, this FAQ section addresses common quality issues encountered in industrial 3D printing environments. By identifying these problems and implementing the suggested solutions, manufacturers can maintain consistent print quality and minimize production disruptions.

Layer adhesion problems

Q: What causes poor layer adhesion in industrial 3D prints?

A: Poor layer adhesion can result from several factors in manufacturing settings, including insufficient extrusion temperature, excessive cooling fan speed, or improper layer height. In industrial applications, this issue often manifests as delamination between layers, compromising the structural integrity of functional parts.

Q: How can I improve layer adhesion in industrial printing?

A: To enhance layer adhesion in manufacturing environments, try increasing the nozzle temperature by 5-10°C, reducing cooling fan speed for the first few layers, and ensuring proper layer height-to-nozzle diameter ratio. For industrial applications requiring high strength, consider using materials specifically formulated for superior layer bonding and adjusting print orientation to optimize layer direction relative to mechanical stress.

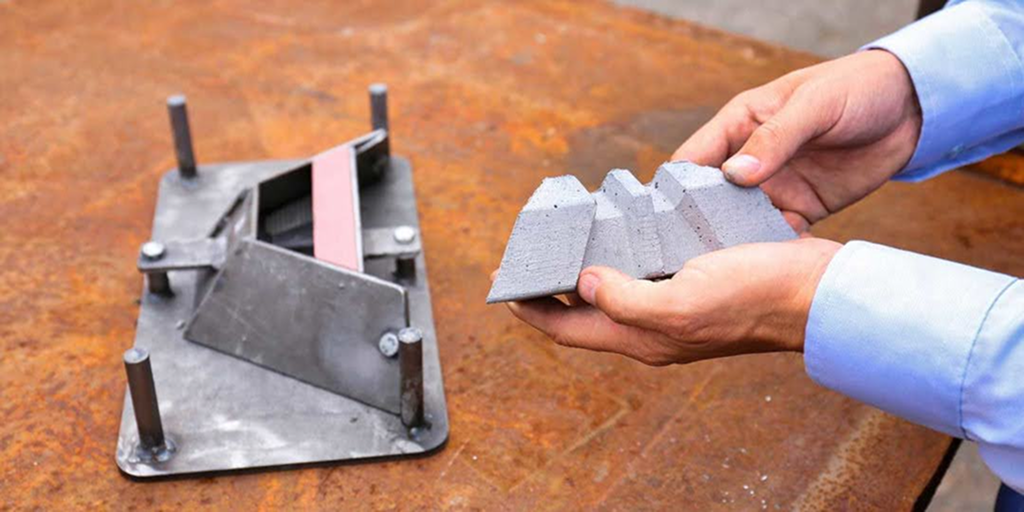

Warping and dimensional accuracy

Q: Why do my industrial prints warp or curl at the corners?

A: Warping occurs when different parts of the print cool at uneven rates in manufacturing settings. This is particularly problematic with high-temperature materials and large industrial parts where thermal stresses are more significant. The result is lifted corners, compromised dimensional accuracy, and potential print failures.

Q: What techniques can prevent warping in industrial 3D printing?

A: To minimize warping in manufacturing applications, ensure proper bed adhesion using appropriate build plate surfaces or adhesives specific to your material. Maintain consistent ambient temperature by using enclosed printing chambers. For large industrial parts, consider using a heated chamber or gradually reducing bed temperature during printing. Adding a brim or raft can also help distribute thermal stresses more evenly across the base of the print.

Stringing and oozing

Q: What causes stringing and how does it affect industrial print quality?

A: In industrial 3D printing, stringing occurs when small threads of plastic are left behind as the print head moves between parts of the model. This not only affects visual quality but can also impact the dimensional accuracy and functionality of precision components in manufacturing.

Q: How can I eliminate stringing in industrial prints?

A: To reduce stringing in manufacturing settings, optimize retraction settings by increasing retraction distance (typically 5-8mm for Bowden setups and 1-3mm for direct drive extruders) and adjusting retraction speed (30-60mm/s is often effective). Additionally, fine-tune printing temperature, as excessive heat can contribute to material oozing. For industrial applications requiring pristine surface finish, consider implementing a coasting feature in your slicer software to reduce pressure in the nozzle before travel moves.

Under-extrusion and gaps

Q: What causes under-extrusion in industrial 3D printing?

A: Under-extrusion in manufacturing environments is characterized by gaps between perimeters, sparse infill, and weak layer bonding. This issue can stem from partial nozzle clogs, incorrect flow rate settings, filament feed issues, or insufficient printing temperature—all of which compromise part strength and dimensional accuracy in industrial applications.

Q: How can I fix under-extrusion problems?

A: To address under-extrusion in industrial settings, first verify that your extruder is properly calibrated using the E-steps calibration process mentioned in our calibration section. Check for potential nozzle blockages by performing cold pulls or using cleaning filament. Ensure consistent filament diameter and quality, as variations can significantly impact extrusion consistency in production environments. Increase nozzle temperature by 5-10°C if filament isn't flowing properly, and verify that cooling fans aren't causing premature solidification of the material before proper layer adhesion occurs.

Over-extrusion and dimensional inaccuracy

Q: How does over-extrusion affect industrial print quality?

A: Over-extrusion in manufacturing leads to excess material deposition, causing dimensional inaccuracies, blob formation, and rough surface finish. In industrial applications requiring precise tolerances, over-extrusion can render parts unusable by exceeding specification limits.

Q: What solutions can address over-extrusion in industrial 3D printing?

A: To mitigate over-extrusion in manufacturing settings, reduce the flow rate in your slicer software by 2-5% increments until optimal results are achieved. Verify that your filament diameter is correctly specified in your slicer settings, as even small discrepancies can significantly impact extrusion volume. For industrial applications requiring tight tolerances, consider implementing linear advance or pressure advance features in your firmware to better control material flow during acceleration and deceleration.

First layer problems

Q: Why is the first layer so critical in industrial 3D printing?

A: In manufacturing environments, the first layer sets the foundation for the entire print. Problems with the first layer can propagate throughout the model, causing warping, poor adhesion, and ultimately print failure. For industrial parts, a compromised first layer can lead to scrapped production runs and material waste.

Q: How can I ensure perfect first layers in industrial applications?

A: To achieve optimal first layers in manufacturing, ensure proper bed leveling using precision feeler gauges or automated mesh bed leveling systems. Adjust the Z-offset carefully to achieve the ideal "squish" of the first layer onto the build plate. For industrial applications, consider using a dedicated adhesion material suited to your build material (such as specific adhesives, PEI surfaces, or specialized build plates). Slowing down the first layer speed by 30-50% compared to normal printing speed allows for better material deposition and adhesion. Additionally, increasing the first layer width by 10-20% can improve adhesion by creating more contact surface with the build plate.