Held every three years in Düsseldorf, Germany, the K trade show is the premier exhibition for the plastics and rubber industry. This year, the Ultimaker Material Alliance was in the spotlight, as many of the world’s leading material companies showcased materials developed for additive manufacturing on Ultimaker 3D printers. K 2019 welcomed approximately 225,000 visitors from 165 countries, and more than 3,300 exhibitors from 63 countries. The show was a perfect opportunity to present Ultimaker as a go-to solution for in-house 3D printing.

“The high number of visitors at K 2019 is a good reflection of the immense scale of the material industry,” Paul Heiden, Senior Vice President Product Management at Ultimaker, said. “It is great to see that additive manufacturing is so high on the agendas of many of these leading material companies.”

Through the Ultimaker Material Alliance, the doors are opening for a vast range of materials, which is rapidly growing, pushing the boundaries of the 3D printing industry. Read on for a rundown of the Ultimaker Material Alliance at K 2019.

The Lehvoss booth at K 2019 showcased its LUVOCOM® 3F filaments, which are suitable for high-performance industrial applications

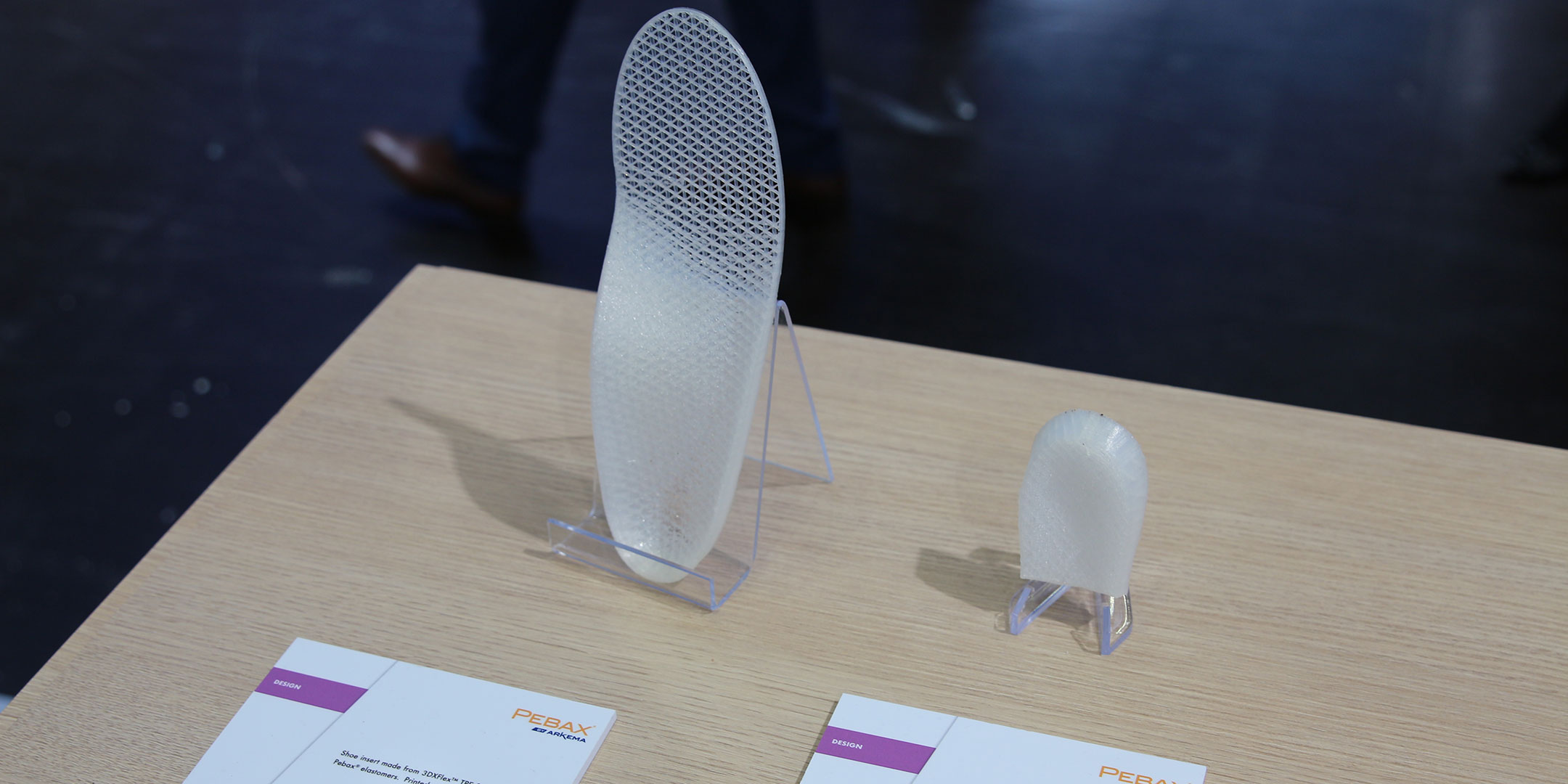

Arkema shared advanced materials and solutions for strong added performance in durability, sustainability, design, program optimization and reinforcement. Arkema showcased shoe inserts and athletic midsoles printed on the Ultimaker S5 with Pebax material; automotive parts printed with Kynar material; and consumer goods parts

Adrien Lapeyre, Arkema's Technical Polymers Global 3D Printing Market Manager, said:

For Arkema, K 2019 was a celebration of ‘durability and sustainability’. Indeed, our portfolio of FFF 3D solutions fits well within this theme. The final parts, printed by Ultimaker using filaments from our partners drew lots of attention from end users wishing to explore applications related to our flagship Pebax® elastomers, and our Kynar® PVDF extreme performance materials. Our motto is ‘An extreme world needs extreme materials’, and we clearly see a bright future in our collaborative journey with Ultimaker and our filament partners.

Arkema showcased shoe inserts and athletic midsoles printed on the Ultimaker S5

Spare parts for a Ducati motorbike presented by DSM Additive Manufacturing

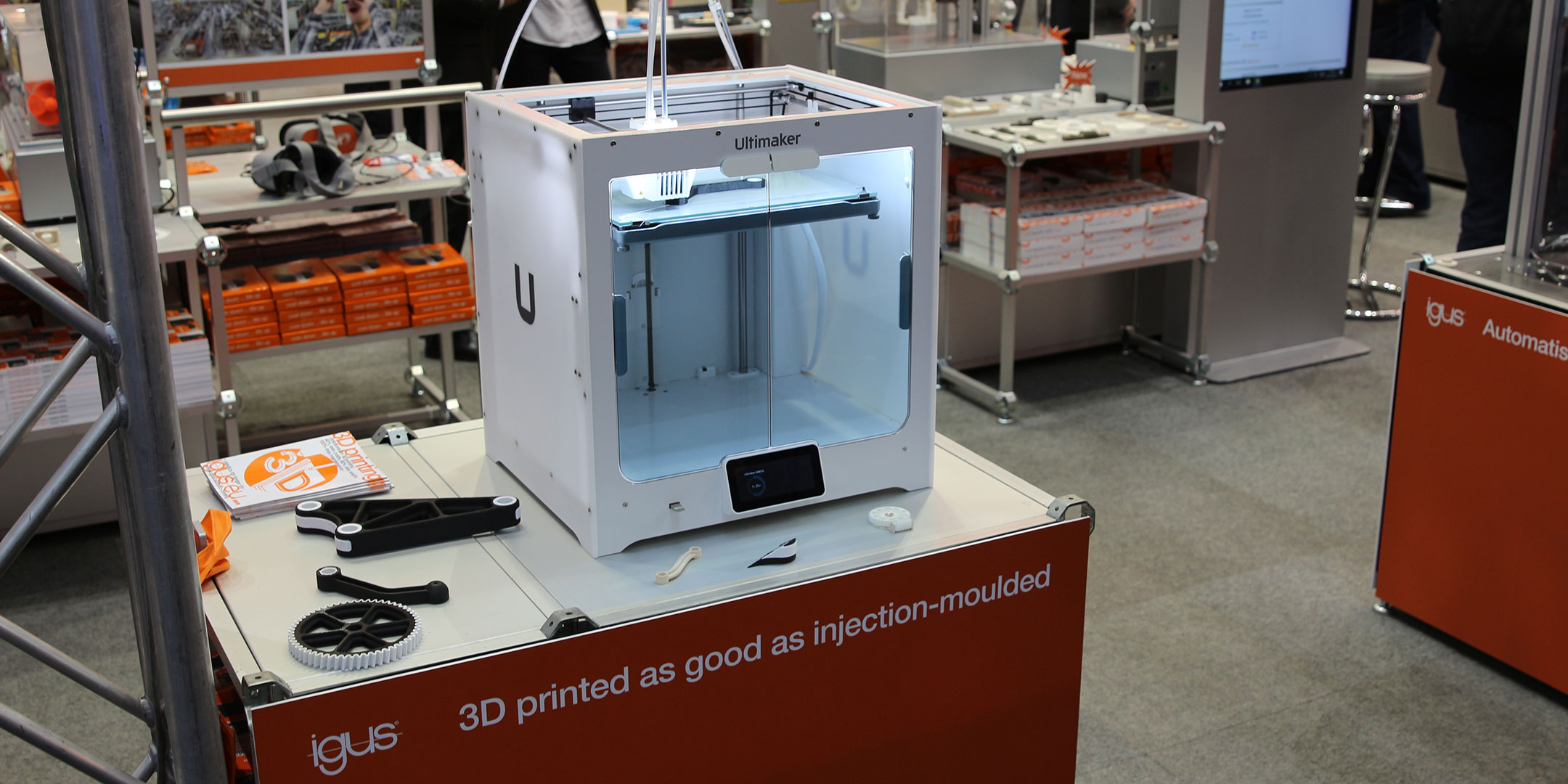

The Igus booth at K 2019, featuring an Ultimaker S5 and 3D printed parts with functional wear properties

Niklas Eutebach, Development Engineer Additive Manufacturing for Igus GmbH, said:

We think that 3D printing has caught traction in a wide field of industries. This is reflected by the lots and lots of different applications and solutions that we provide to our customers every day. We’ll continue to broaden our portfolio of materials by listening to our customer’s demands, adding filaments to enable more and more difficult use cases.

Huntsman's TPU filament delivers less friction in the filament guiding tubes, resulting in reliable prints for applications requiring softness, flexibility, and durability

Unlock new applications

Ready to explore new applications with 3D printing? Download the latest version of Ultimaker Cura for free and discover the print profiles available on the Ultimaker Marketplace.