Welcome back to our application spotlight series, where we showcase real-world 3D printed parts that drive smarter, faster, and more efficient manufacturing. Each week, we dive into practical examples that highlight how additive manufacturing solves everyday industrial challenges.

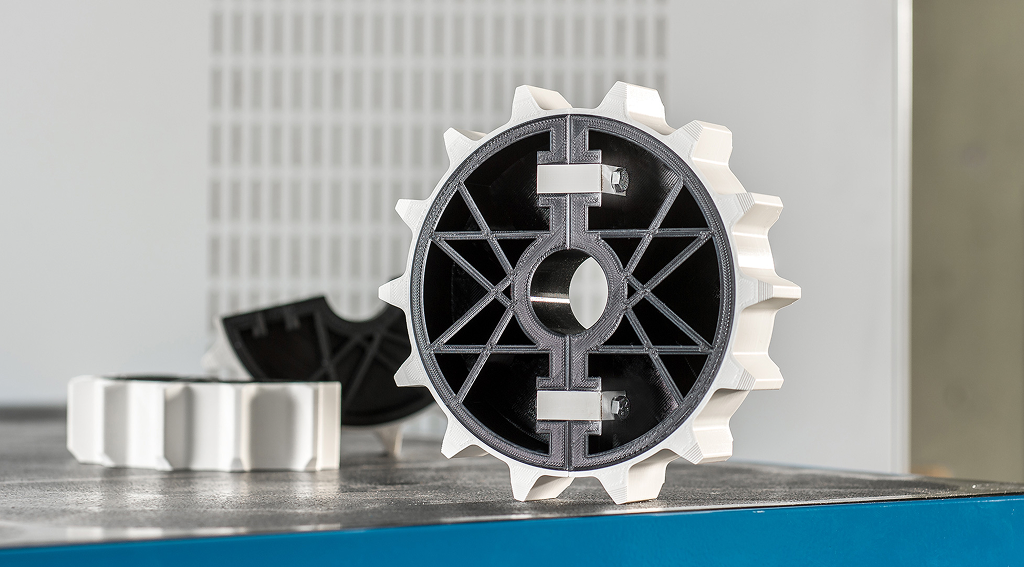

This week, we’re turning our attention to a custom 3D printed sprocket wheel: A small but powerful component essential to keeping conveyor systems moving.

Driving performance with 3D printing

Sprocket wheels are used in conveyor lines in the food and beverage processing sectors. Their role? To engage with conveyor chains or belts and drive a continuous, smooth motion across the line. Precision is critical- any misalignment or mechanical failure can lead to product jams, lost time, and increased costs.

Traditionally, sprockets are manufactured from stainless steel, machined nylon, or high-strength polymers - durable, yes, but often slow and expensive to produce. And when it comes to custom specifications like unique tooth counts, diameters, or bore sizes, the costs and lead times quickly add up.

Using 3D printing, manufacturers can now produce custom sprocket wheels faster and more cost-effectively, without compromising on strength or performance.

This sprocket wheel was optimized for performance by printing the sprocket with PET CF, a rigid and strong technical material as well as UltiMaker Nylon CF Slide, known for its excellent wear resistance and low friction properties. This dual-material strategy allowed for faster print times without sacrificing durability.