Optimizing print speed with the fastest infill patterns

While strength is often a primary concern, print speed can be equally important, especially for rapid prototyping or large production runs. Fortunately, certain infill patterns are designed to minimize printing time without significantly compromising structural integrity. For tips on further increasing your printing speed, see how to 3D print faster.

Speed optimization often involves compromises, and infill pattern selection is an effective way to reduce printing time without sacrificing functionality. The fastest patterns use simplified geometry and continuous printing paths that minimize printer head movement.

Lines or rectilinear infill is often the fastest due to its geometry and efficient paths. The pattern consists of parallel lines alternating direction, creating long extrusion paths that allow the printer to maintain speed. This simplicity reduces printing time, making lines infill a good choice for rapid prototyping and non-critical uses where speed is important.

Lightning infill is optimized for speed. This pattern places material only where needed to support the outer walls. Lightning infill can reduce printing time while using less material. However, this speed reduces structural integrity, making lightning infill suitable only for display models, prototypes, and non-functional uses.

Zigzag infill offers a balance between the speed of lines infill and slightly better strength. By creating continuous back-and-forth paths without lifting the print head, zigzag infill maintains speed while providing better structural performance. This pattern works well for parts needing some internal structure but not maximum strength.

Balancing infill density and print quality

Achieving the ideal 3D print involves more than just selecting a pattern; it requires fine-tuning infill density to strike a balance between strength, print quality, and material usage. Understanding how infill density affects these factors is essential for optimizing your results.

The relationship between infill percentage and print quality involves interactions between structural integrity, surface finish, material use, and printing time. Achieving good results requires understanding how infill density affects these factors.

Infill density affects strength. While higher percentages generally increase strength, this relationship isn't linear, and the point of diminishing returns varies depending on the pattern and loading conditions. For many uses, densities between 20% and 40% provide good strength-to-weight ratios while maintaining reasonable printing times and material use.

The infill overlap percentage setting controls how well the internal structure bonds with the outer walls. Proper overlap ensures the infill supports the perimeter walls, preventing delamination and improving part integrity. Insufficient overlap can lead to weak bonds, while excessive overlap can cause over-extrusion and surface issues. Most uses benefit from overlap percentages between 10% and 25%, depending on the material and printing conditions.

Don’t ignore wall count: two extra perimeters often add more strength than raising infill from 20 % → 30 %. Treat shells as the primary load path; infill is backup.

Surface quality also influences infill density. Low percentages can sometimes cause visible surface imperfections, particularly on large flat surfaces where insufficient internal support allows the outer walls to sag. High densities may cause surface bulging due to internal stresses during cooling. Finding the right balance ensures both structural performance and aesthetic quality.

Advanced infill techniques for optimal results

For those seeking to push the boundaries of 3D printing, advanced infill techniques offer a pathway to creating parts with exceptional performance and efficiency.

These methods provide granular control over material placement, allowing for optimized structures tailored to specific needs.

Variable infill density is a technique available in software. This allows different regions of the same part to use different densities, concentrating material where strength is needed while reducing it in less critical areas.

For example, a bracket might use high-density infill in stress-bearing regions while using minimal infill in decorative sections. This requires careful analysis but can result in material savings without compromising performance.

Adaptive infill adjusts infill density based on the geometric needs of different part regions. Areas with thin walls, overhangs, or complex geometry automatically receive higher density, while thick-walled regions use lower density to save material and time.

Specialized infill types offer benefits for specific uses. These patterns combine geometric principles to create internal structures optimized for particular loading conditions. Understanding when and how to apply these types can improve print quality, making the difference between adequate and good results.

But advanced tricks only help if the printer is dialled in - run through this quick checklist first:

- Nozzle diameter ≥ 0.4 mm (or adjust line-width settings)

- Flow/extrusion multiplier calibrated with a single-wall test cube

- Minimum printable feature ≥ 1.2 × nozzle diameter

- Bed level & first-layer height verified across the build plate

- Filament dry (especially PETG, ABS, nylon)

- Cooling-fan profile matched to the material

- Firmware and slicer up to date

Conclusion

Remember that while theoretical knowledge is invaluable, practical experimentation remains key. Don't hesitate to print test specimens, iterate on your designs, and push the boundaries of what's possible with your 3D printer. As the technology continues to evolve, staying curious and open to new techniques will help you stay at the forefront of 3D printing innovation.

By applying the knowledge gained from this guide and continuing to explore new possibilities, you'll be well-equipped to tackle even the most challenging 3D printing projects with confidence.

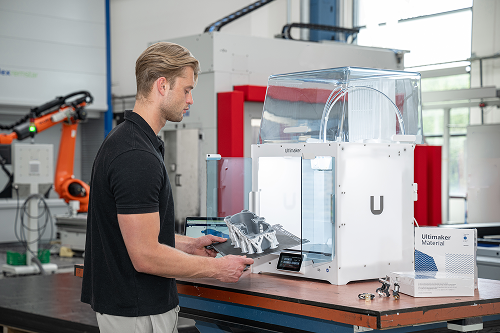

Advanced 3D printers like the UltiMaker S8 can expand your possibilities, whether you're creating rapid prototypes, end-use parts, or pushing the limits of additive manufacturing, the world of infill patterns offers a vast playground for optimization and creativity.

Further reading and resources